🚀 A nagy hatékonyságú műanyag-újrahasznosító berendezések végső útmutatója!

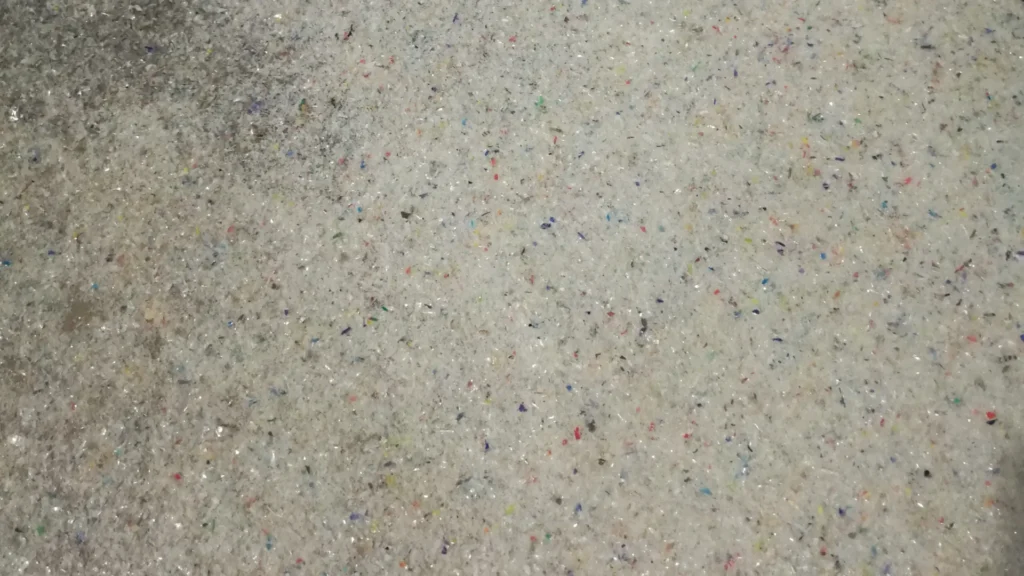

Készen állsz fellendíteni a műanyag-újrahasznosítási teljesítményedet? Merülj el részletes leírásunkban a legfontosabb gépekről, amelyek egy csúcskategóriás újrahasznosítási gyártósort működtetnek! A masszív szállítószalagoktól és a nagy teljesítményű granulátoroktól a hatékony szeparátorokig és a fejlett mosótartályokig mindent megtalálsz nálunk, amire szükséged van. Ez a 310 kW teljes beépített teljesítménnyel és óránként 1000-1500 kg hulladék előállítására alkalmas rendszer csúcsteljesítményre lett tervezve. Ez a tökéletes útiterv azoknak a vállalkozásoknak, amelyek optimalizálni szeretnék műanyag-újrahasznosítási műveleteiket, és valódi változást szeretnének elérni! ✨

Részletes berendezésspecifikációk

| Gép leírása | Specifikációk | Mennyiség (darab) |

|---|---|---|

| 1. Szállítószalag 1 | 1) Szalag szélessége: 800㎜ 2) Öv anyaga: PVC 3) Motorteljesítmény: 2,2 kW 4) Redukciós arány: 1:30 5) Hajtógörgő átmérője: φ273㎜ 6) A szalag lineáris sebessége: 0,63 m/s 7) Meghajtott görgő átmérője: φ323㎜ | 1 |

| 2. Granulátor | 1) Fő motor: 45 kW 2) Vágófej forgó átmérője: φ630㎜ 3) Vágófej szélessége: 1150㎜ 4) Forgó kések száma: 10 db 5) Állító kések száma: 4 db 6) Vágóanyag: SKD11 7) Vágófej forgási sebessége: 462 fordulat/perc 8) Vágófej anyaga: 45-ös acél 9) Szitaszövet: φ95㎜ 10) Hidraulikus nyitott adagológarat/hidraulikus szitaváltó 11) Hidraulikus állomás teljesítménye: 2,2 kW 12) Kapacitás: 1000-1200 kg/h 13) Átviteli teljesítmény: 3KW 14) Sebességváltó modell: NMRV130-30 15) Csavaros szállítószalag forgási sebessége: 20-72,5 fordulat/perc állítható 16) Csavarlapát átmérője: φ250㎜ 17) Csavartávolság: 200㎜ 18) Csavar anyaga: rozsdamentes acél | 1 |

| 3. Csavaros szállítószalag 1 | 1) Motorteljesítmény: 3,7 kW 2) Csigaszállító forgási sebessége: 20-72,5 ford/perc 3) Csavarlapát átmérője: φ390㎜ 4) Csavarlöket: 300㎜ 5) Csavar anyaga: rozsdamentes acél 6) Váz anyaga: szénacél | 1 |

| 4. Film- és pehelyleválasztó | 1) Anyag: rozsdamentes acél 2) Váz anyaga: szénacél | 1 |

| 5. Szélküldő rendszer | 1) Fúvómotor: 5,5 kW 2) Csőátmérő: φ159㎜ 3) Csőanyag: rozsdamentes acél | 1 |

| 6. Címkék tárolása | 1) Tárolóanyag: rozsdamentes acél 2) Térfogat: 2 m³ | 1 |

| 7. Csigaszállító 2 | 1) Motorteljesítmény: 3,7 kW 2) Csigaszállító forgási sebessége: 20-72,5 ford/perc 3) Csavarlapát átmérője: φ390㎜ 4) Csavarlöket: 300㎜ 5) Csavar anyaga: rozsdamentes acél 6) Váz anyaga: szénacél | 1 |

| 8. Mosótartály | 1) Belső szélesség: 1500㎜ 2) Teljes hossz: 5000㎜ 3) Anyag: rozsdamentes acél 4) Váz anyaga: szénacél 5) Alsó csavarmotor: 5,5 kW 6) Kiürítő anyagú csavarmotor: 3,7 kW 7) Emelőcsiga motor teljesítménye: 3KW 8) Fő motor teljesítménye: 3KW | 2 |

| 9. Forró (kazános) mosógép | 1) Motorteljesítmény: 7,5 kW 2) Reduktor modell: BLD5-71-7.5 3) Keverőtengely forgási sebessége: 20 fordulat/perc 4) Fűtőteljesítmény: 60 kW 5) Kazán anyaga: rozsdamentes acél 6) Átviteli teljesítmény: 3,7 kW 7) Reduktor modell: NMRV110-20 8) Csavar forgási sebessége: 20-72,5 fordulat/perc, állítható 9) Csavarlapát átmérője: φ290㎜ 10) Csavaros távtartó: 200㎜ 11) Csavar anyaga: rozsdamentes acél | 2 |

| 10. Nagy sebességű súrlódó alátét | 1) Rotor forgási átmérője: φ524㎜ 2) Rotor anyaga: szénacél 3) Rotor forgási sebessége: 960 fordulat/perc 4) Rotorlapátok száma: 24 db 5) Alátét test: rozsdamentes acél 6) Hatékony mosási hossz: 2800㎜ 7) Motorteljesítmény: 37 kW 8) Szállítási szög: 15° 9) Vezetési mód: szíjhajtás | 1 |

| 11. Csigaszállító 3 | 1) Motorteljesítmény: 3,7 kW 2) Csigaszállító forgási sebessége: 20-72,5 ford/perc 3) Csavarlapát átmérője: φ390㎜ 4) Csavarlöket: 300㎜ 5) Csavar anyaga: rozsdamentes acél 6) Váz anyaga: szénacél | 1 |

| 12. Víztelenítő gép | 1) Fő motor teljesítménye: 75 kW 2) A gép belső anyaga: rozsdamentes acél 3) Rotor forgó átmérője: φ850㎜ 4) Rotor anyaga: szénacél | 1 |

| 13. Termikus szárító | 1) Csőátmérő: φ159㎜ 2) Fúvóteljesítmény: 5,5 kW 3) Csőanyag: rozsdamentes acél 4) Fúvó modell: 9-19 NO.4X55 5) Fűtőteljesítmény: 30 kW | 2 |

| 14. Ciklonleválasztó | 1) Szeparátor átmérője: φ1000㎜ 2) Anyag: rozsdamentes acél | 1 |

| 15. Késztermék siló | 1) Siló anyaga: rozsdamentes acél 2) Siló térfogata: 2,5 m³ | 1 |

| 16. Elektromos panel | Központosított vezérlőrendszer | 1 |

| Összesen | Telepített teljesítmény: 310 kW Kapacitás: 1000–1500 kg/h |

Kezdjük el a projektedet! 🤝

Itt a Rumtoo újrahasznosítás, kiváló színvonalat biztosítunk PET palackmosó sorok Úgy terveztük, hogy a legtöbb újrahasznosító létesítmény igényeit kielégítse. De itt nem állunk meg! Szüksége van valami egyedire? Szakterületünk a PET újrahasznosító üzemek egyedi tervezése és telepítése, amelyeket pontosan az Ön alkalmazásához, kapacitási követelményeihez és specifikációihoz igazítunk. Bármi legyen is a projektje, számíthat ránk a kiváló ügyfélszolgálat és a világos kommunikáció terén a folyamat minden lépésében. Izgatottan segítünk életre kelteni újrahasznosítási elképzelését!