Mennyibe kerül egy műanyag-újrahasznosító vállalkozás indítása?

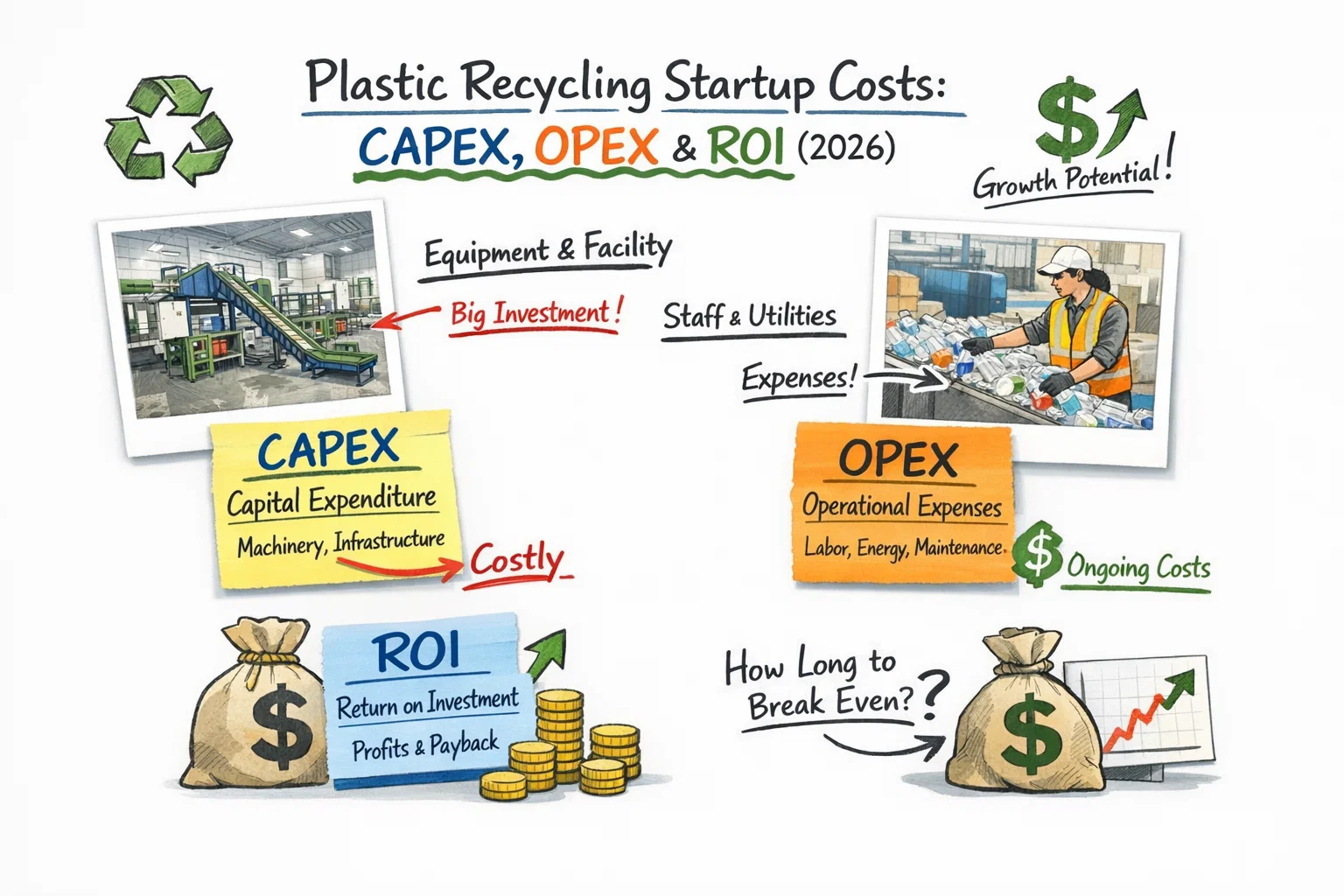

Egy műanyag-újrahasznosító vállalkozás indítása tőkeigényes döntés, amelyet a CAPEX, az OPEX és a hosszú távú működési hatékonyság határoz meg. Ez az útmutató a reális indulási költségeket ismerteti egy... közepes méretű ipari újrahasznosító üzem, bemutatva, hogy hová megy a pénz, és mely döntések befolyásolják a legközvetlenebbül a jövedelmezőséget és a megtérülési időt.

Gyors költség-pillanatkép

Az alábbi tartományok tükrözik közepes méretű ipari starterüzem aprítással, mosással és opcionális pelletizálással. A kisebb kísérleti projektek és a nagy, teljesen automatizált üzemek kívül eshetnek ezeken a tartományokon.

Tipikus befektetési tartomány

- Teljes induló befektetés: $400 000 – $1 300 000+

- Gépek és technológiai berendezések: 40–501 TP7T a teljes CAPEX-ből

- Létesítmény és közművek: 20–301 TP7T a teljes CAPEX-ből

- Működőtőke: legalább 3 hónap ajánlott

A jövedelmezőség fő mozgatórugói

- Berendezések üzemideje és megbízhatósága

- Pellet vagy pehely minősége és állaga

- Energia- és vízfogyasztás tonnánként

- Bejövő és kimenő logisztikai hatékonyság

CAPEX áttekintés

A tőkekiadások magukban foglalnak mindent, ami egy működőképes, megfelelő létesítmény eléréséhez szükséges. A CAPEX-döntéseket nehéz visszafordítani, és hosszú távú hatással vannak az üzemi haszonkulcsra.

Tipikus CAPEX összetevők

- Hulladékfeldolgozó gépek és segédberendezések

- Épületbérlés, felújítás vagy vásárlás

- Elektromos korszerűsítések és energiaelosztás

- Vízelvezető és vízelvezető rendszerek

- Tűzvédelmi és környezetvédelmi előírások

Gyakran figyelmen kívül hagyott tételek

- Telepítés és üzembe helyezés

- Alkatrészek és karbantartó eszközök

- Anyagszállító rendszerek

- Minőség-ellenőrző és vizsgáló berendezések

- Vészhelyzeti költségvetés (5–15%)

Gépek és berendezések költségei

Becsült tartomány: $200 000 – $800 000+

A berendezések minősége a legfontosabb tényező, amely befolyásolja a hosszú távú megtérülést (ROI). Az olcsó gépek gyakran magasabb energiafogyasztást, gyakori állásidőt és inkonzisztens termékminőséget eredményeznek.

A fejlett válogatással, melegmosással és olvadékszűréssel felszerelt nagy kapacitású gyártósorok az áteresztőképességtől és az automatizálási szinttől függően túlléphetik ezt a tartományt.

| Folyamatfázis | Tipikus felszerelés | Cél |

|---|---|---|

| Méretcsökkentés | Aprítók, granulátorok, fémszétválasztás | Anyag előkészítése mosáshoz és extrudáláshoz |

| Mosás és elválasztás | Súrlódó alátétek, úszómosó tartályok, forró mosás | Távolítsa el a szennyeződéseket és javítsa a tisztaságot |

| Szárítás | Víztelenítő egységek, termikus szárítók | Stabilizálja a nedvességet az extrudálás előtt |

| Extrudálás és pelletizálás | Extruderek, szűrők, pelletizálók | Egyenletes újrahasznosított pelletek előállítása |

Létesítmény és infrastruktúra

Becsült tartomány: $50,000 – $300,000 (lízing/felújítás) · $1M+ (vásárlás)

- Minimum ~10 000 négyzetláb szabványos ipari vezetékekhez

- Háromfázisú ipari áramellátás és korszerűsített panelek

- Vízszűrés és szennyvíz megfelelőség

- Tűzvédelem és biztonsági övezetek

Alapanyag-beszerzés

Becsült tartomány: $20,000 – $50,000 (kezdeti készlet)

A bálázott műanyag nem ingyenes. Az ár a polimer típusától, a szennyeződéstől és a regionális ellátástól függ. Az ipari utáni forrásokkal kötött stabil szerződések csökkentik az ingadozást és javítják a haszonkulcsokat.

Szállítás és logisztika

Becsült tartomány: $5,000 – $25,000 havonta

A szállítási hatékonyság hiánya eltörölheti a profitot. A forrásnál történő tömörítés, az optimalizált útvonaltervezés és a kiegyensúlyozott tárolás kritikus fontosságú.

Engedélyek, megfelelőség és biztosítás

Becsült tartomány: $15,000 – $40,000

Az újrahasznosító létesítményeket ipari hulladékkezelő műveletekként szabályozzák. A legtöbb joghatóságban kötelező a környezetvédelmi engedélyek, a tűzvédelmi előírások betartása és a speciális biztosítás.

Munka és képzés

Becsült tartomány: $50 000 – $150 000

Még az automatizált üzemekben is szükség van képzett kezelőkre és technikusokra. A képzésre és a megelőző karbantartásra szánt költségvetés védi az üzemidőt.

OPEX valóság

Tipikus üzemeltetési költségek

- Villany és víz

- Munkaerő- és bérterhek

- alapanyag-vásárlások

- Karbantartás és fogyóeszközök

- Bejövő és kimenő áruk

Margóvédelmi stratégiák

- Upstream szennyeződés-szabályozás

- Stabil áteresztőképességű kialakítás

- Rutinszerű leálláselemzés

- Egyértelmű vevői specifikációk

Megtérülés és fedezeti pont

A jól működő ipari újrahasznosító üzemek gyakran 18–24 hónapon belüli nyereségküszöb elérését célozzák meg, ha teljesülnek az áteresztőképességi és minőségi célok. A berendezések üzemideje a legfontosabb teljesítménymutató.

Induló költségek összefoglalása

| Költségkategória | Becsült tartomány (USD) |

|---|---|

| Gépek és berendezések | $200 000 – $800 000+ |

| Létesítmény és közművek | $50 000 – $300 000 |

| Alapanyag-készlet | $20,000 – $50,000 |

| Engedélyek és megfelelés | $15,000 – $40,000 |

| Logisztika és anyagmozgatás | $20,000 – $80,000 |

| Működőtőke | $100 000 – $200 000 |

| Teljes befektetés | $400 000 – $1 300 000+ |

Következő lépések

A polimer típusának, a szennyeződési szintnek, a célzott kimenetnek és a kapacitásnak a meghatározása a leggyorsabb módja a költségvetés finomításának és a kockázat csökkentésének.

Fedezze fel a teljes újrahasznosítási munkafolyamatokat és rendszerlehetőségeket a következő címen: Energycle Újrahasznosítási megoldások.

GYIK

Elég az $300,000 az induláshoz?

Kis vagy speciális beállításoknál működhet, de a legtöbb ipari üzem nagyobb költségvetéssel rendelkezik a stabil áteresztőképesség és az állandó minőség elérése érdekében.

Mi a legnagyobb rejtett költség?

Az elektromos korszerűsítések, a vízkezelés és az állásidők a leggyakoribb meglepetések. A logisztikai hatékonyság hiánya csendben ronthatja a haszonkulcsokat is.

Pehely vagy pellet?

A pehely előállításához alacsonyabb beruházási költségekre van szükség, és egyszerűbb a termelés. A pelletek szabványosabbak a vásárlók számára, de szigorúbb folyamatszabályozást és szűrést igényelnek.