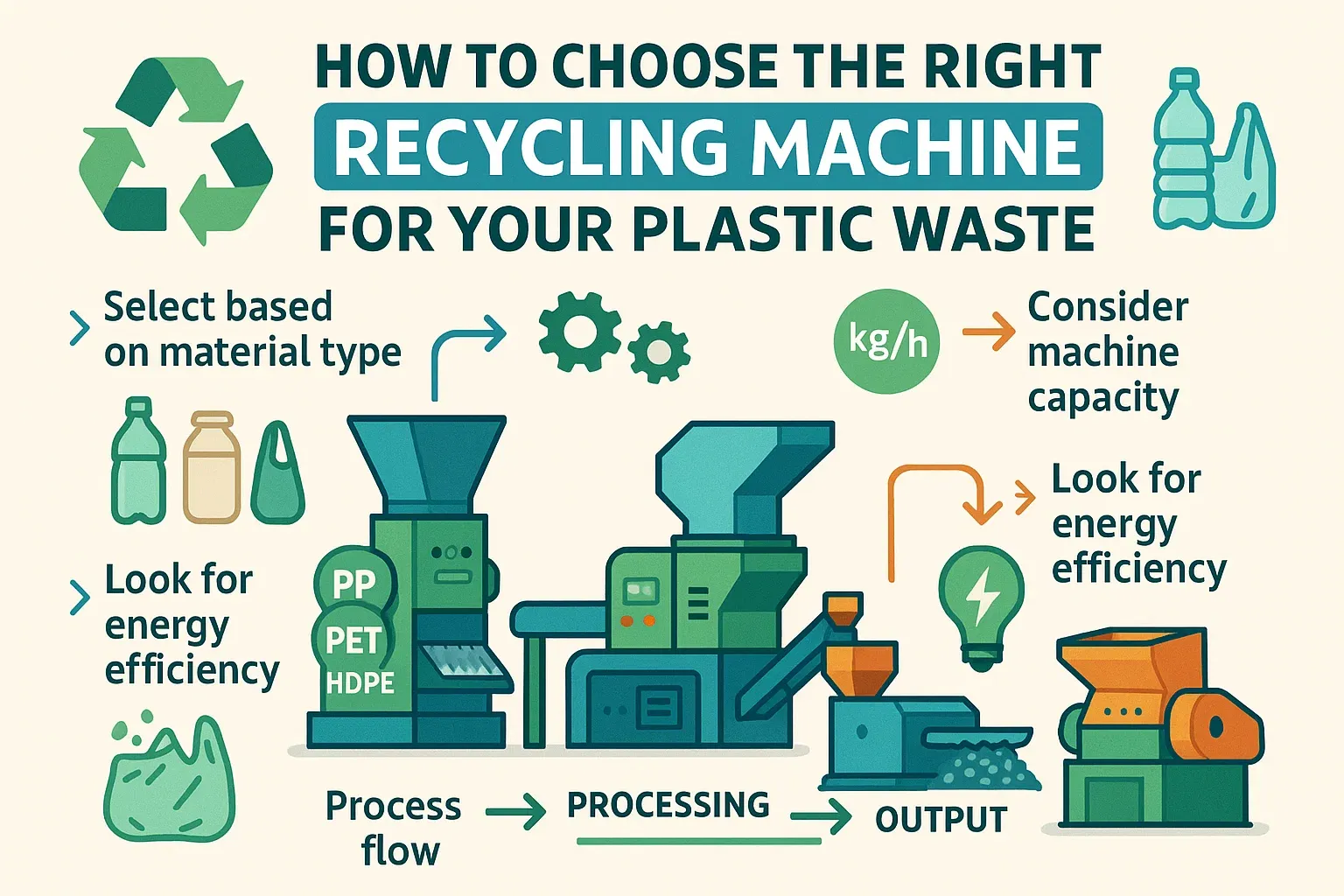

Nell'attuale settore del riciclaggio in rapida evoluzione, la scelta della macchina giusta è fondamentale per trattare i rifiuti plastici in modo efficace ed efficiente. Che si operi nel riciclaggio della plastica, nella gestione dei rifiuti o nella produzione, disporre dell'attrezzatura giusta non solo aumenta l'efficienza operativa, ma contribuisce anche al raggiungimento degli obiettivi di sostenibilità. Questo articolo fornisce una guida completa per aiutare gli acquirenti di attrezzature industriali, gli ingegneri e il personale tecnico a scegliere la macchina ideale per il riciclaggio in base al tipo e al volume di rifiuti plastici da trattare.

Capire i tipi di rifiuti plastici

Prima di addentrarci nella scelta della macchina, è fondamentale comprendere i tipi di rifiuti plastici che si stanno trattando. Le diverse plastiche hanno proprietà distinte che influenzano il modo in cui possono essere trattate. Ecco una panoramica dei tipi di plastica più comuni e le relative considerazioni sul riciclaggio:

- Polietilene (PE) e polipropilene (PP): Queste plastiche sono comuni nei materiali di imballaggio come bottiglie, sacchetti e contenitori. Sono termoplastiche, il che significa che possono essere riscaldate, rimodellate e riciclate più volte.

- Cloruro di polivinile (PVC): Presente in tubi, pavimenti e prodotti medicali, il PVC è più rigido e richiede macchinari specializzati in grado di gestire le sue proprietà uniche.

- Polietilene tereftalato (PET): Ampiamente utilizzato in bottiglie e contenitori, il PET è altamente riciclabile, ma spesso richiede una pulizia accurata per rimuovere i contaminanti.

- Polistirene (PS):Utilizzato negli imballaggi e nei prodotti monouso, il PS è leggero, ma può essere difficile da riciclare a causa della sua fragilità e della tendenza a rompersi in piccoli pezzi.

- Plastica mista: Spesso le aziende si imbattono in rifiuti plastici misti. Ciò richiede macchinari in grado di trattare più tipi di plastica, solitamente attraverso una combinazione di sistemi di triturazione, lavaggio e selezione.

Fattori chiave da considerare quando si sceglie un Macchina per il riciclaggio

Per scegliere la macchina giusta è necessario valutare diversi fattori chiave in base alle proprie esigenze. Analizziamo gli aspetti più importanti da considerare:

1. Tipo e composizione dei rifiuti plastici

La composizione dei tuoi rifiuti plastici determinerà il tipo di macchina per il riciclaggio di cui hai bisogno. Ad esempio:

- Plastiche monomateriale (come il PET o l'HDPE) possono essere lavorati in modo più efficiente con un trituratore o un granulatore dedicato.

- Plastica mista richiedono un sistema di riciclaggio versatile in grado di selezionare, triturare e lavare i materiali contemporaneamente.

2. Capacità di elaborazione

La capacità di lavorazione della macchina deve essere commisurata al volume di rifiuti plastici trattati. Le macchine in genere variano in termini di produttività, da sistemi a lotti su piccola scala (ideali per bassi volumi) a macchine a flusso continuo su larga scala, adatte a volumi più elevati.

3. Efficienza della macchina

Le macchine per il riciclaggio variano in termini di consumo energetico, velocità e produttività. Valutate l'efficienza delle macchine per assicurarvi che soddisfino i vostri requisiti di produzione senza incorrere in costi operativi eccessivi.

4. Automazione e integrazione

Le funzionalità di automazione stanno diventando sempre più importanti per ridurre i costi di manodopera e minimizzare l'errore umano. Le macchine integrabili con altri sistemi, come le unità di selezione e lavaggio, contribuiscono a semplificare il processo di riciclaggio. Assicuratevi che la macchina scelta offra opzioni di automazione in linea con le esigenze del vostro stabilimento.

5. Manutenzione e durata

L'affidabilità di una macchina e la facilità di manutenzione sono fattori chiave per le prestazioni a lungo termine. Macchine difficili da manutenere possono causare costosi tempi di fermo. Optate per attrezzature progettate per durare a lungo e dotate di caratteristiche che semplificano la manutenzione, come l'accesso senza attrezzi o i componenti modulari.

Tipi di macchine per il riciclaggio dei rifiuti plastici

Ora che abbiamo compreso i fattori che influenzano la scelta della macchina, esploriamo i diversi tipi di macchine comunemente utilizzate nel riciclaggio della plastica.

1. Trituratori di plastica

I trituratori sono tra i macchinari più comunemente utilizzati per il trattamento dei rifiuti plastici. Funzionano tagliando la plastica in pezzi più piccoli, più facili da gestire e processare nelle successive fasi di riciclo.

- Adatto per: Grandi oggetti in plastica, imballaggi e altri articoli che devono essere scomposti.

- Caratteristiche principali: Modelli a doppio albero o ad albero singolo, impostazioni variabili delle lame, elevata potenza.

2. Granulatori di plastica

I granulatori sono simili ai trituratori, ma sono più specializzati nel ridurre la plastica in granuli più piccoli e uniformi. Sono particolarmente utili per le materie plastiche che devono essere riprocessate o per preparare i materiali per l'estrusione.

- Adatto per: Bottiglie in PET, pellicole e altri prodotti in plastica rigida.

- Caratteristiche principali: Granuli di dimensioni variabili, funzionamento a risparmio energetico.

3. Estrusori

Gli estrusori vengono utilizzati per fondere e modellare la plastica in nuove forme o pellet. Si tratta di una macchina fondamentale per creare nuovi prodotti in plastica da materiali riciclati. Viene comunemente utilizzata nella fase finale del riciclo, dopo che la plastica è stata triturata e granulata.

- Adatto per: Rifiuti di plastica di grandi dimensioni, che producono pellet da reintegrare nei processi produttivi.

- Caratteristiche principali: Alte temperature per la fusione, sistemi di alimentazione a coclea e teste di filiera per la pellettizzazione.

4. Sistemi di lavaggio

I rifiuti di plastica contengono spesso contaminanti come etichette, sporco o oli. I sistemi di lavaggio rimuovono queste impurità per garantire che la plastica riciclata sia di alta qualità.

- Adatto per: PET, HDPE e altre materie plastiche che richiedono una pulizia accurata prima del riutilizzo.

- Caratteristiche principali: Idropulitrici ad alta pressione, vasche di flottazione e sistemi di asciugatura.

5. Selezionatori e separatori

Per i rifiuti di plastica mista, selezionatrici e separatori aiutano a distinguere i diversi tipi di plastica, rendendo il processo di riciclo più efficiente. Queste macchine utilizzano aria o mezzi meccanici per separare i materiali in base alla densità o alle dimensioni.

- Adatto per: Plastica mista, garantendo che i diversi tipi di plastica vengano separati per un riciclaggio efficace.

- Caratteristiche principali: Separatori a zig-zag, classificatori ad aria, separatori magnetici.

Confronto delle prestazioni: selezione della macchina per diversi tipi di rifiuti plastici

| Tipo di plastica | Macchina adatta | Caratteristiche principali | Capacità | Efficienza |

|---|---|---|---|---|

| Bottiglie in PET | Trituratore, Granulatore, Estrusore | Materiale pulito, elevata produttività, buon flusso di fusione | 500-3000 kg/h | Alto |

| Contenitori in HDPE | Trituratore, Granulatore, Lavatrice | Pulizia efficace, granuli uniformi | 500-1500 kg/ora | Alto |

| Plastica mista | Trituratore, Selezionatore, Lavatrice | Selezione e lavaggio versatili e multistadio | 500-2000 kg/ora | Medio |

| Tubi in PVC | Trituratore, Granulatore, Lavatrice | Taglio ad alta potenza e precisione per materie plastiche rigide | 300-100 kg/ora | Medio |

Conclusione: scegliere la macchina per il riciclaggio giusta per i tuoi rifiuti di plastica

Scegliere il giusto macchina per il riciclaggio Dipende dal tipo di rifiuti plastici che stai trattando, dalla capacità della macchina e dall'efficienza necessaria per le tue operazioni. Considerando fattori come la composizione della plastica, l'automazione della macchina e la durata, puoi garantire che la tua azienda raggiunga la massima efficienza mantenendo risultati di riciclo di alta qualità.

Con la continua evoluzione delle tecnologie di riciclo, è importante rimanere aggiornati sulle innovazioni che potrebbero ottimizzare ulteriormente i processi di riciclo della plastica. Con le attrezzature giuste, è possibile trasformare i rifiuti in risorse preziose, contribuendo a un ambiente di produzione più sostenibile.

Cerchi la macchina per il riciclaggio giusta?

Se hai bisogno di ulteriore assistenza nella scelta della macchina per il riciclaggio più adatta alle tue esigenze, non esitare a contattare gli esperti del settore che possono fornirti consigli e supporto personalizzati per le tue specifiche esigenze di riciclaggio.