PP Meltblown Pelletizing Line

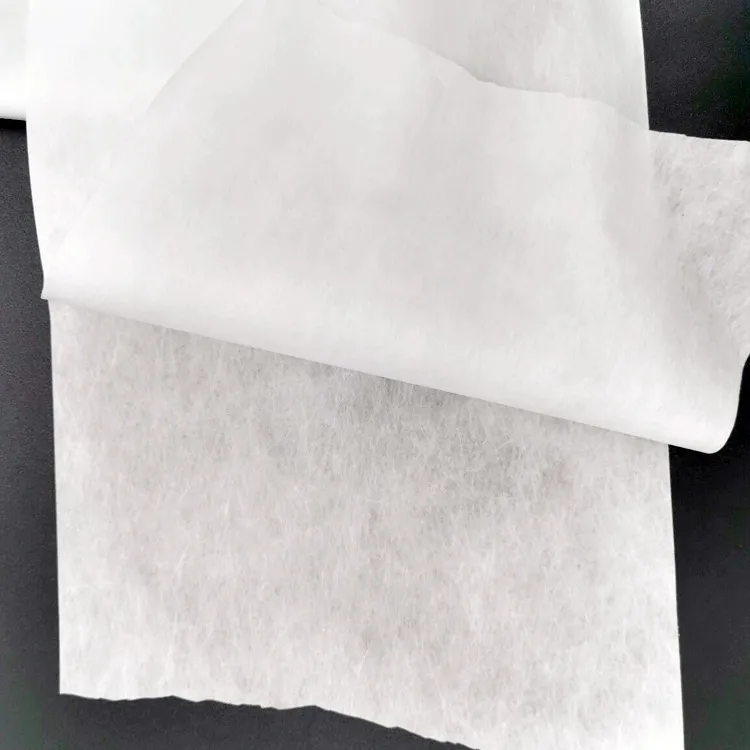

The ultimate in-house recycling solution. Transform post-industrial PP meltblown nonwoven scrap into valuable, high-quality pellets.

Get a Custom QuoteCore Operational Advantages

Specifically engineered to handle light, fluffy nonwoven scrap without pre-processing.

In-House Recycling

Immediately reprocess your production waste. Turn scrap back into raw material, reducing virtually all waste disposal costs.

MFI Preservation

Gentle plasticization ensures minimal degradation, retaining the critical Melt Flow Index (MFI) for reuse in nonwoven production.

Superior Degassing

Double-zone vacuum degassing efficiently removes moisture and spin finish oils, ensuring bubble-free pellets.

Smart Automation

Features an intelligent PLC control system that synchronizes feeding, extruding, and pelletizing for stable 24/7 operation.

Extrusion Process Flow

A straightforward, highly efficient process from loose scrap to packaged pellets.

1. Anti-Bridging Feeding

Belt conveyor feeds fluffy MFI>1000 scrap into the cutter-compactor. The system actively densifies material to 300kg/m³, preventing bridging.

2. Extrusion & Plasticization

The densified material is fed directly into the extruder screw. Gentle heating and shearing melt the plastic without degradation.

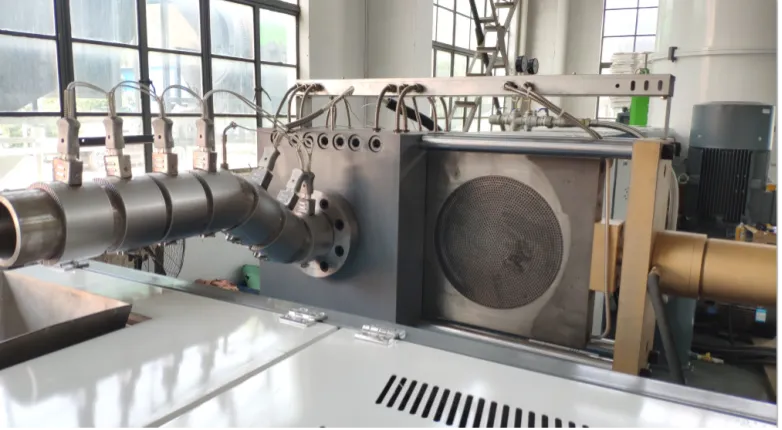

3. Precision Filtration

Dual-piston screen changers allow non-stop operation even with high MFI material, filtering down to 100 mesh without pressure drops.

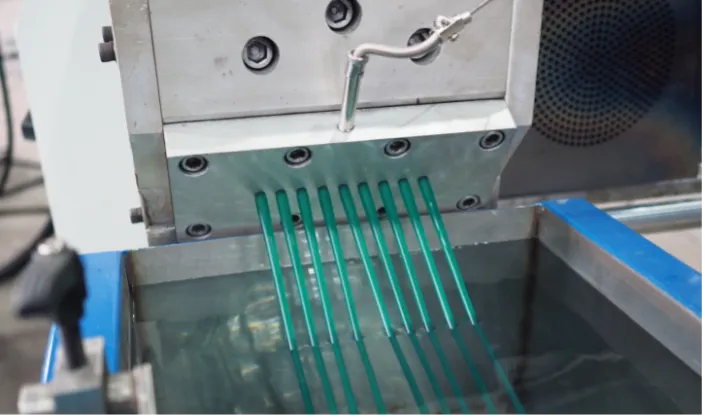

4. Pelletizing

The die-face water ring pelletizer cuts the melt into uniform pellets, which are immediately cooled and dried.

Machine Specifications

| Model | Screw Dia. (mm) | Compactor Power (kW) | Extruder Power (kW) | Capacity (kg/h) |

|---|---|---|---|---|

| SJ85 | 85 | 37 | 45 | 160 - 220 |

| SJ100 | 100 | 55 | 90 | 300 - 380 |

| SJ120 | 120 | 90 | 132 | 450 - 550 |

| SJ160 | 160 | 132 | 250 | 800 - 1000 |

Equipment Operation Showcase

Robust design meets high performance. See our machines in action.

Warranty & Satisfaction Guarantee

Reliability you can count on. We support your operation for the long haul.

Standard Warranty

12 months for major components (screw, barrel, motor, gearbox). Extended coverage available.

Remote Support

Lifetime technical support via video call and email for troubleshooting and optimization.

Spare Parts

Detailed parts list provided. Critical spares stocked for fast global dispatch.

Installation & Training

On-site engineer avaialble for commissioning and staff training to ensure peak efficiency.

Technical Support & FAQ

Why use a cutter-compactor for meltblown fabric?

Meltblown fabric has very low bulk density. The cutter-compactor pre-densifies the material, generates frictional heat to remove surface moisture, and force-feeds the material into the extruder. Without it, the extruder would struggle to accept the light material, leading to low output and surging.

Can recycled pellets be used for new masks/filters?

Yes. Because our machine minimizes thermal degradation, the MFI change is negligible. Many clients blend 20-30% of our recycled pellets back into their meltblown lines for non-critical layers or structural nonwovens.

What is the lead time for a complete line?

Standard lead time is 45-60 days from order confirmation. This allows for rigorous quality control and testing of the machine with your specific material before shipment.

Start Turning Waste into Profit

Get a custom drawing and ROI analysis for your facility today.