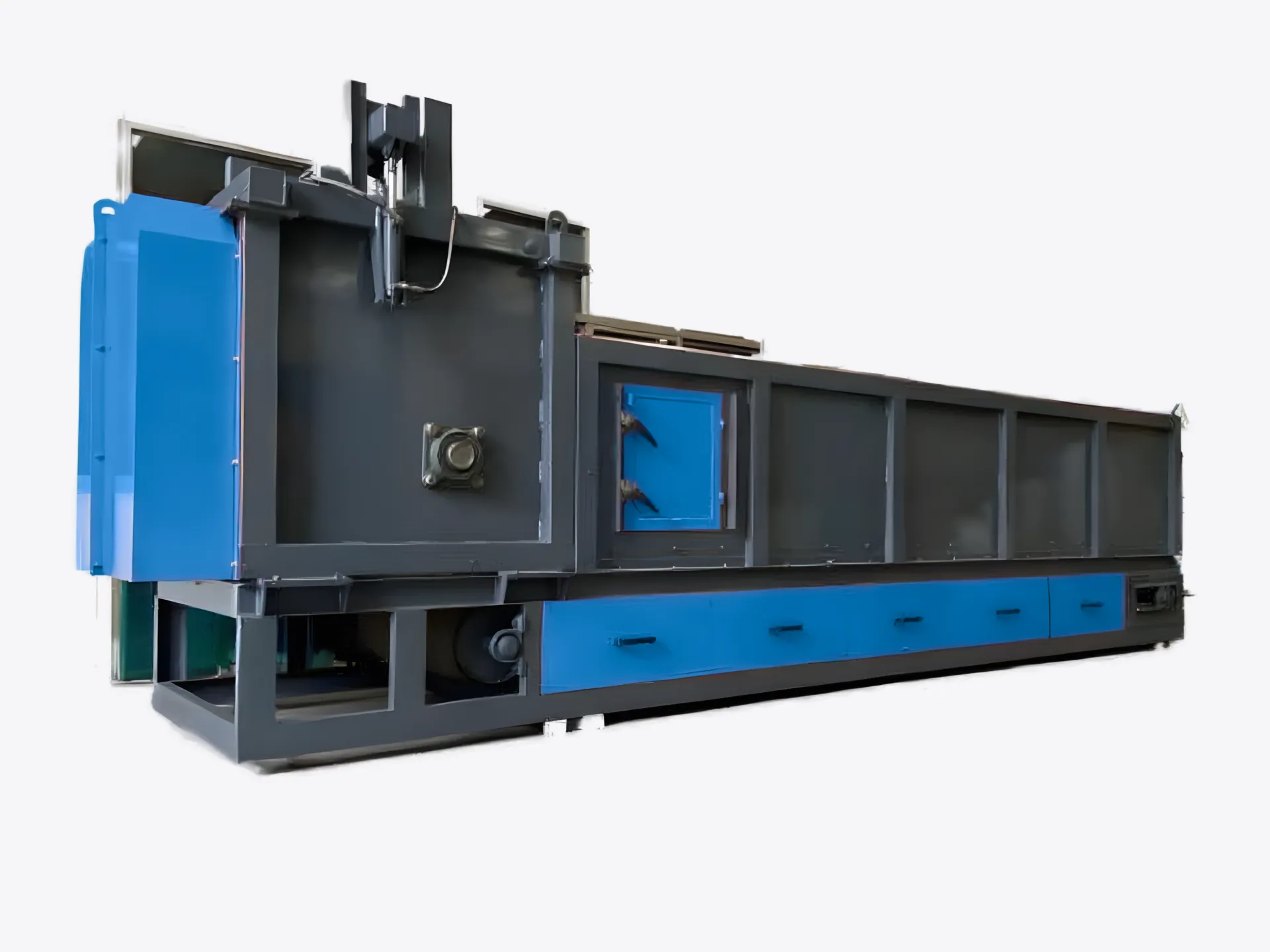

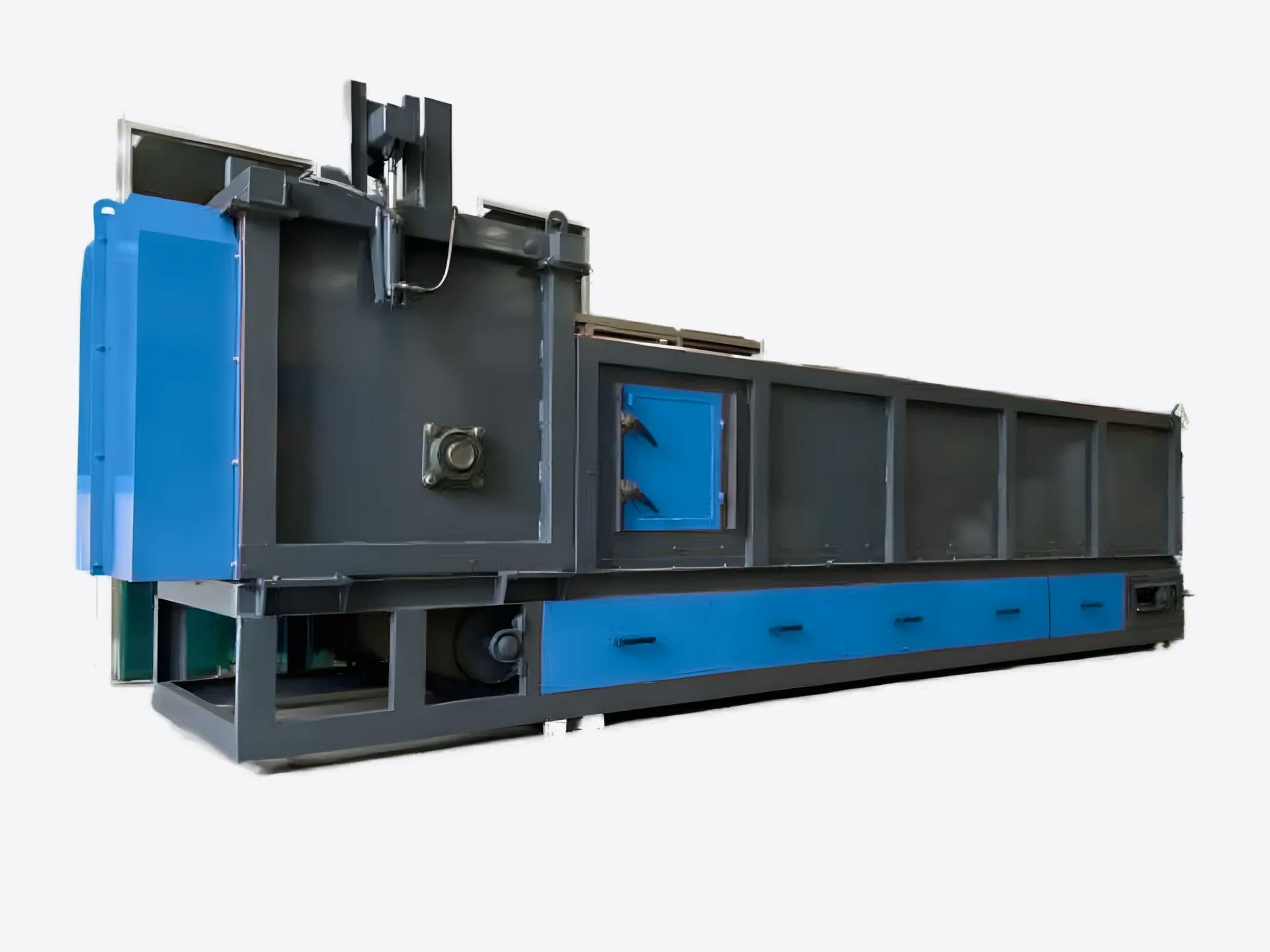

Quebrador de sacos e abridor de fardos inteligente

A solução front-end robusta e de alta eficiência para linhas de triagem de RSU e reciclagem de PET em larga escala.

Obtenha uma solução personalizada e orçamentoPontos fortes do núcleo

Projetado para ambientes exigentes, criado para aumentar significativamente sua eficiência operacional e automação.

Versatilidade Poderosa

Processa com eficiência resíduos sólidos urbanos ensacados e fardos compactados de alta densidade de garrafas PET ou filmes plásticos.

Libertação Excepcional

Atinge uma taxa de abertura de saco de mais de 98% e descompacta fardos de forma eficaz sem danificar o material do núcleo.

Resistente e durável

Construído com materiais de alta resistência e resistentes ao desgaste, além de um sistema de transmissão de alta resistência para confiabilidade a longo prazo sob altas cargas.

Como funciona

Um processo simplificado para liberar dois tipos distintos de materiais.

Resíduos Sólidos Urbanos (RSU) Ensacados

Fardos de PET compactados

Fluxo de material liberado e uniforme

Pronto para classificação posterior

Características técnicas

Cada detalhe é meticulosamente projetado para desempenho superior e custos operacionais reduzidos.

Facas modulares resistentes ao desgaste

Facas de liga de aço especialmente tratadas termicamente podem ser substituídas individualmente, minimizando o tempo de inatividade e os custos de manutenção.

Sistema de controle inteligente

Possui controle PLC com regulação adaptável à carga, reversão automática para evitar atolamentos e recursos de monitoramento remoto.

Proteção Avançada do Sistema de Transmissão

Equipado com proteção contra sobrecarga mecânica e elétrica, além de vedações de labirinto para evitar contaminação de rolamentos por poeira.

Eixo anti-emaranhamento otimizado

Um eixo principal especialmente estruturado evita que filmes, tecidos e outros materiais flexíveis se enrolem, garantindo uma operação contínua.

Especificações técnicas

| Parâmetro | Modelo BO-30 | Modelo BO-50 | Modelo BO-80 |

|---|---|---|---|

| Capacidade de processamento (t/h) | 5-10 | 10-20 | 20-30 | Materiais aplicáveis | RSU ensacado, fardos de garrafas de PET/PEAD, fardos de filme, outros plásticos compactados |

Aplicações e Galeria

De instalações de resíduos urbanos a grandes usinas de reciclagem de plásticos, nossos equipamentos são comprovados em campo.

Comece seu próximo capítulo em reciclagem eficiente

Entre em contato conosco hoje mesmo para obter uma solução personalizada e um orçamento detalhado adaptado ao seu fluxo de materiais específico.

Perguntas frequentes

Ao processar fardos de PET, as garrafas são danificadas?

Não, não. Nossa máquina opera com base no princípio de "liberação", não de "trituração". As facas de baixa velocidade e alto torque são projetadas para rasgar as cintas dos fardos e separar delicadamente as garrafas comprimidas. Qualquer contato com as garrafas resulta apenas em pequenos arranhões, o que não afeta os processos de triagem óptica ou lavagem subsequentes.

Qual é a vida útil e o custo de reposição das facas?

As facas são feitas de aço-liga de alta resistência ao desgaste e têm uma vida útil típica de 1500 a 2000 horas de operação. Apresentam um design modular, permitindo a substituição fácil e individual apenas das partes desgastadas. Oferecemos preços competitivos em peças de reposição para garantir que seus custos operacionais a longo prazo permaneçam baixos.

Esta máquina pode ser integrada à minha linha de produção existente?

Com certeza. Fornecemos interfaces de entrada e saída padronizadas que se conectam perfeitamente a diversos transportadores (placas, correias) e equipamentos posteriores, como peneiras rotativas. Nossos engenheiros também podem auxiliar no planejamento do layout da sua linha para garantir uma integração perfeita.