Texas leads the nation in energy production, and that activity generates massive amounts of post-consumer LDPE films. Operators use these flexible polyethylene films for packaging, drum liners, rig covers, and protective wraps across oilfields and gas facilities. Once used, these films often end up contaminated with sand, oil residues, and dirt, which complicates recycling efforts.

Energy companies in Texas face a clear choice. You can send this material to landfills, or you can turn it into valuable pellets for reuse. High-capacity mechanical processing offers a reliable path forward. At Energycle, we help facilities across the state handle thousands of pounds per hour of dirty LDPE films with equipment built for real-world industrial conditions.

Why LDPE Film Waste Builds Up in Texas Energy Operations

The oil and gas industry relies on LDPE films for their strength and flexibility. Workers use them to protect equipment, line containers, and bundle materials on site. After use, these films collect contaminants common in Texas fields:

- Sand and soil from drilling sites

- Oil and chemical residues

- Mixed labels or tapes

These issues make standard recycling lines struggle. Films wrap around shafts, clog filters, or produce low-quality output. Many Texas facilities bale and store this waste, waiting for viable options. Recent market shifts, including facility closures like WM’s Natura PCR plant, highlight the need for on-site or regional mechanical solutions that deliver consistent results.

Core Challenges in Processing Dirty Post-Consumer LDPE Films

You know the problems firsthand when you deal with this material daily. Dirty LDPE films demand equipment that handles contamination without constant downtime. Common hurdles include:

- High contamination levels — Sand abrades standard blades and reduces pellet quality.

- Baixa densidade aparente — Loose films take up huge volumes in storage and transport.

- Variable moisture — Field-exposed films retain water that affects extrusion.

Facilities that overcome these produce clean, uniform pellets ready for new film or injection molding. The key lies in robust preprocessing and extrusion systems designed specifically for contaminated feeds.

High-Capacity Equipment That Handles Texas Tough Conditions

Energy sector operators need systems that process 2,000 to 5,000 pounds per hour or more. We recommend integrated lines that combine heavy-duty shredding, densification, and extrusion.

Specialized Shredders for Dirty Films

Standard granulators fail on contaminated films because material wraps or floats. Single-shaft shredders with high-torque motors cut through sandy, oily LDPE cleanly. These machines feature reinforced blades and screens that resist wear from abrasives. Learn more about specialized shredders for film recycling on our guide.

Densifiers and Squeezers for Volume Reduction

After shredding, densifiers or squeezers compress fluffy flakes into dense granules. This step removes air and residual moisture while achieving compression ratios up to 50:1. The result: easier feeding into extruders and lower transport costs. See details on plastic film squeezers and density gains.

High-Output Extruders and Pelletizers

Twin-screw or single-screw extruders with strong filtration systems melt and clean the material. Multiple screen changers catch sand and contaminants before pelletizing. Water-ring or strand pelletizers then produce uniform pellets suitable for resale or reuse.

All Energycle systems run on standard U.S. industrial power: 480V, 60Hz, 3-phase. This compatibility means no costly transformers or rewiring when you install in Texas facilities.

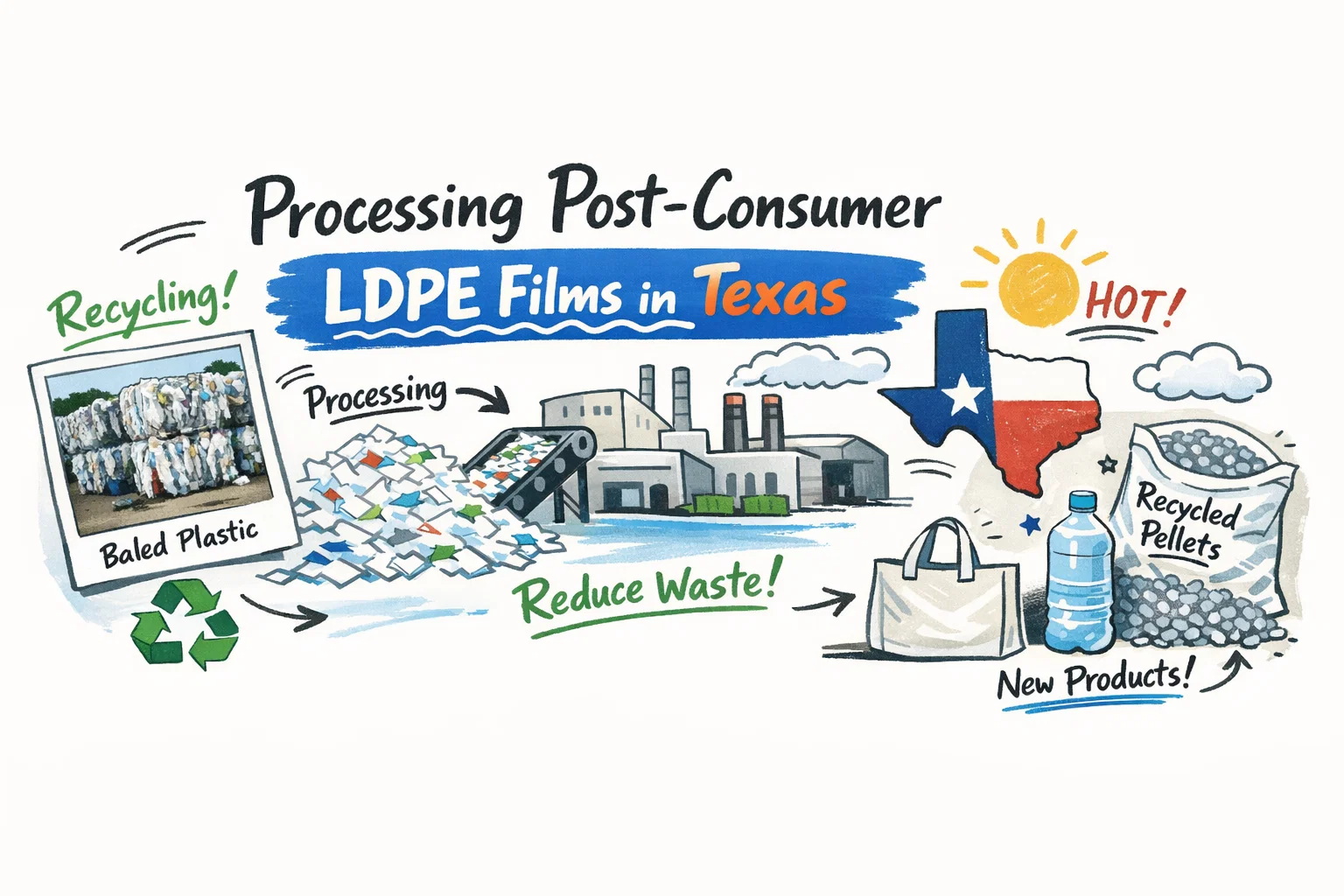

Step-by-Step Guide to Set Up Your LDPE Film Processing Line

Follow these practical steps to process dirty post-consumer LDPE films effectively:

- Collect and Sort → Bale films on site and separate obvious non-plastics like metal straps.

- Shred → Feed bales into a high-torque shredder to create uniform pieces.

- Densify → Run shredded material through a squeezer or agglomerator to boost density and remove moisture.

- Extrude and Filter → Melt the densified material and push it through fine screens to remove contaminants.

- Pelletize and Cool → Cut hot strands or die-face pellets and cool them for packaging.

This mechanical approach produces pellets with melt indexes suitable for film blowing or molding. Many Texas operators achieve payback in 12 to 24 months through avoided disposal fees and pellet sales.

Real Benefits for Texas Energy Companies

Facilities that invest in high-capacity lines gain control over waste streams. You reduce landfill costs, meet sustainability goals, and create a new revenue source from pellets. The U.S. Environmental Protection Agency notes that mechanical recycling conserves energy and reduces emissions compared to virgin resin production.

The American Chemistry Council reports growing demand for post-consumer resins in packaging applications.

Texas energy operators also benefit from local support and equipment designed for American power standards. Energycle systems stand up to the sandy, oily conditions common in Permian Basin and Eagle Ford operations.

Ready to process your post-consumer LDPE films at scale? Contact Energycle for a custom line consultation built for Texas energy needs. Explore our LDPE film densification solutions or complete pelletizing guide to get started.

External resources: