Recycling News

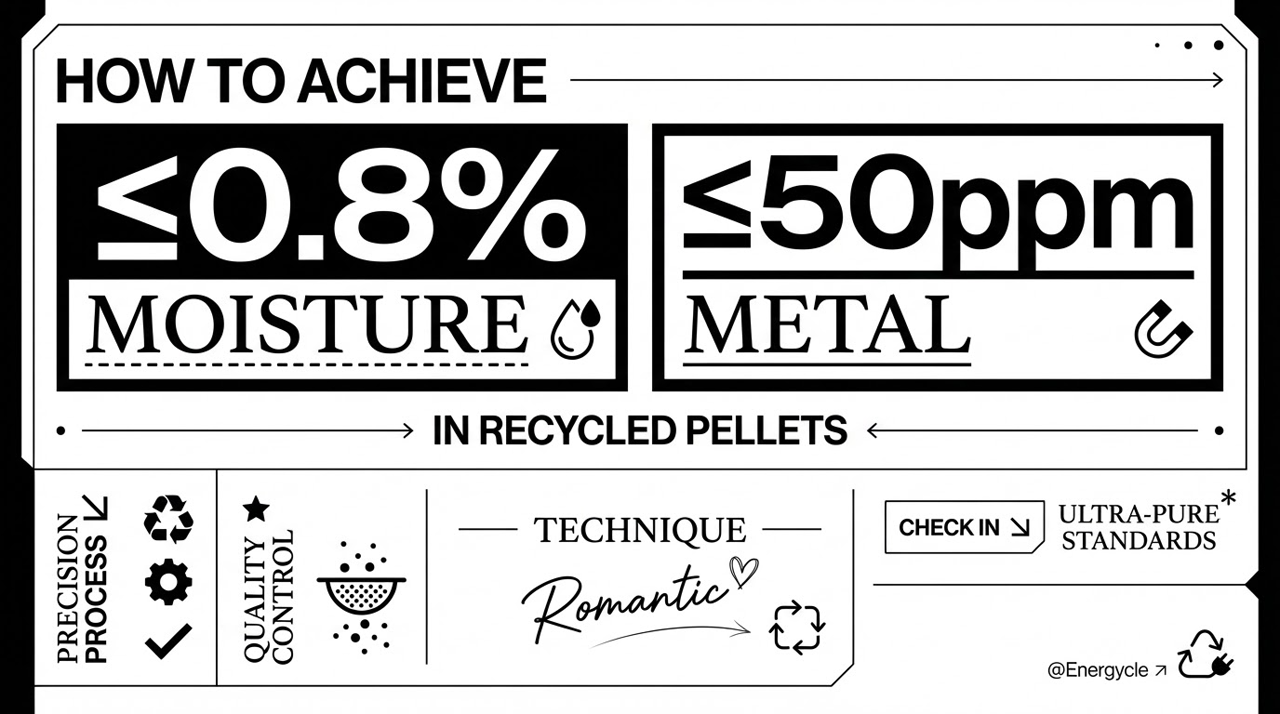

At Energycle, we process thousands of tons of PET bottles each year. We have tested both wet and dry crushing methods in real facilities. Time and again, wet crushing proves its value for operators who aim for high-quality flakes and smooth operations.

Wet crushing adds water directly into the crushing chamber as bottles feed in. This simple step changes the entire process. Water cools the material, rinses away dirt, and helps separate labels early. Dry crushing skips the water, which keeps setup basic but brings challenges like dust and heat.

Operators often ask us why we recommend wet crushing for most PET lines. The reasons come down to better results, lower long-term costs, and easier maintenance. Let us break down the main advantages we see every day.

Superior Contaminant Removal from the Start

Water acts as a built-in rinse during crushing. As blades shred bottles, water washes away sand, grit, paper pulp, and loose adhesives right away. This prevents contaminants from embedding into PET flakes.

In dry systems, labels and glue can smear across surfaces when heat builds up. That forces extra cleaning steps later. With wet crushing, flakes arrive cleaner at the washing stage. Facilities we work with report up to 30% less residue after initial crushing.

This early cleaning pays off in purer output that meets strict standards for food-grade rPET.

Protection of Material Quality and Intrinsic Viscosity

PET degrades when it gets too hot. Friction in dry crushers raises temperatures quickly, which lowers intrinsic viscosity (IV). Lower IV means weaker pellets and lost value.

Water keeps everything cool. It absorbs heat and prevents thermal damage. Tests in our lines show wet-crushed flakes retain higher IV values, often by 0.05–0.1 points compared to dry methods.

Buyers pay more for consistent, high-IV material. Wet crushing helps you deliver flakes that command better prices without extra treatments.

Extended Equipment Life and Reduced Maintenance

Dry crushing creates heavy wear on blades and screens. Abrasive particles like sand grind against metal without lubrication.

Water cushions the action and flushes abrasives away. Blades stay sharper longer, and screens clog less often. Operators tell us they replace blades 40–50% less frequently with wet systems.

Fewer breakdowns mean more uptime and lower repair costs over time.

Safer, Cleaner, and Quieter Operations

Dry crushing produces clouds of dust and plastic particles. That raises safety risks and requires strong ventilation.

Wet methods control dust almost completely. Water binds particles, so the workspace stays cleaner and workers face fewer hazards.

Noise drops noticeably too. The water dampens blade impacts, creating a quieter plant that keeps teams comfortable during long shifts.

Energy Efficiency and Consistent Performance

Water creates a smoother load on motors. Power draw stays steady instead of spiking during tough feeds.

Many lines we install use less electricity overall with wet crushing, even after accounting for pumps. The gains come from efficient cutting and reduced friction.

Practical Tips to Maximize Wet Crushing Benefits

Choose the right water flow. Start at 5–10% of material weight and adjust based on contamination levels. Our wet PET bottle crushers are designed with adjustable water injection systems to make this optimization easy.

Add a pre-sort step. Remove caps and heavy dirt before crushing to ease the load.

Maintain proper pH in the water. Neutral or slightly alkaline levels help loosen labels without harming PET.

Recycle process water. Use filtration and settling tanks to reuse it and cut fresh water needs by up to 70%.

Pair with strong downstream washing. Wet crushing handles the first clean; follow with hot wash and friction separators for top purity.

We guide every Energycle customer through these adjustments during setup. Small changes often boost output quality fast.

Interested in full PET recycling lines? Check our PET bottle washing systems or compare options on our PET recycling equipment guide.

Insights from Industry Sources

Experts back these advantages. A detailed look at wet grinding in plastics recycling highlights reduced power use, quieter runs, and better control of fly-back material. Studies on crushing methods also show wet processes enrich pure components more effectively.

For broader PET recycling context, the EPA notes high recovery potential when processes minimize degradation.

Wet crushing stands out for serious PET recyclers. It delivers cleaner flakes, protects material value, cuts maintenance, and creates a better work environment. Initial setup costs more than dry systems, but the returns in quality and efficiency add up quickly.

Contact Energycle if you want to explore wet crushing for your operation. We share real data from installations that match your scale.

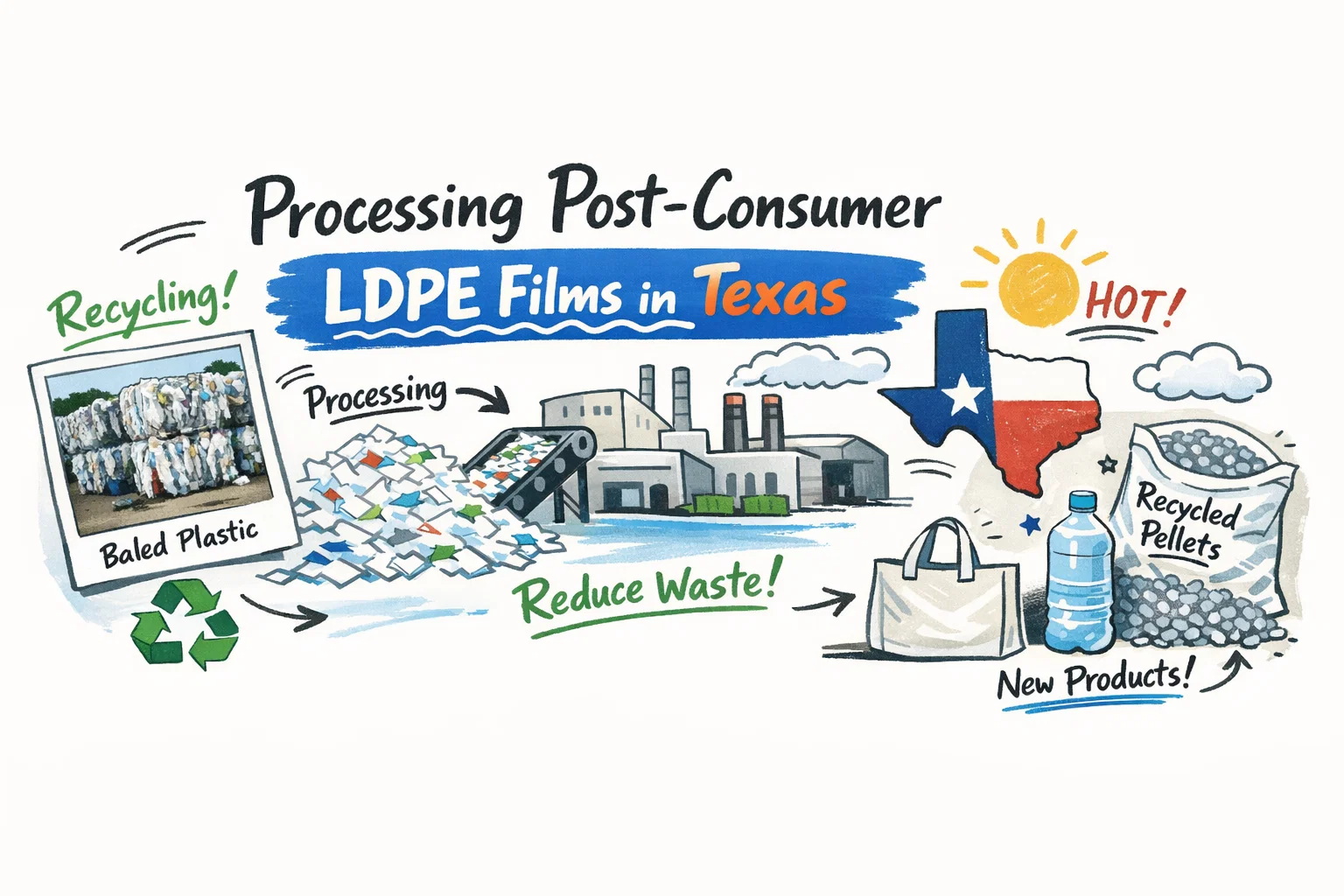

Texas leads the nation in energy production, and that activity generates massive amounts of post-consumer LDPE films. Operators use these flexible polyethylene films for packaging, drum liners, rig covers, and protective wraps across oilfields and gas facilities. Once used, these films often end up contaminated with sand, oil residues, and dirt, which complicates recycling efforts.

Energy companies in Texas face a clear choice. You can send this material to landfills, or you can turn it into valuable pellets for reuse. High-capacity mechanical processing offers a reliable path forward. At Energycle, we help facilities across the state handle thousands of pounds per hour of dirty LDPE films with equipment built for real-world industrial conditions.

Why LDPE Film Waste Builds Up in Texas Energy Operations

The oil and gas industry relies on LDPE films for their strength and flexibility. Workers use them to protect equipment, line containers, and bundle materials on site. After use, these films collect contaminants common in Texas fields:

- Sand and soil from drilling sites

- Oil and chemical residues

- Mixed labels or tapes

These issues make standard recycling lines struggle. Films wrap around shafts, clog filters, or produce low-quality output. Many Texas facilities bale and store this waste, waiting for viable options. Recent market shifts, including facility closures like WM's Natura PCR plant, highlight the need for on-site or regional mechanical solutions that deliver consistent results.

Core Challenges in Processing Dirty Post-Consumer LDPE Films

You know the problems firsthand when you deal with this material daily. Dirty LDPE films demand equipment that handles contamination without constant downtime. Common hurdles include:

- High contamination levels — Sand abrades standard blades and reduces pellet quality.

- Low bulk density — Loose films take up huge volumes in storage and transport.

- Variable moisture — Field-exposed films retain water that affects extrusion.

Facilities that overcome these produce clean, uniform pellets ready for new film or injection molding. The key lies in robust preprocessing and extrusion systems designed specifically for contaminated feeds.

High-Capacity Equipment That Handles Texas Tough Conditions

Energy sector operators need systems that process 2,000 to 5,000 pounds per hour or more. We recommend integrated lines that combine heavy-duty shredding, densification, and extrusion.

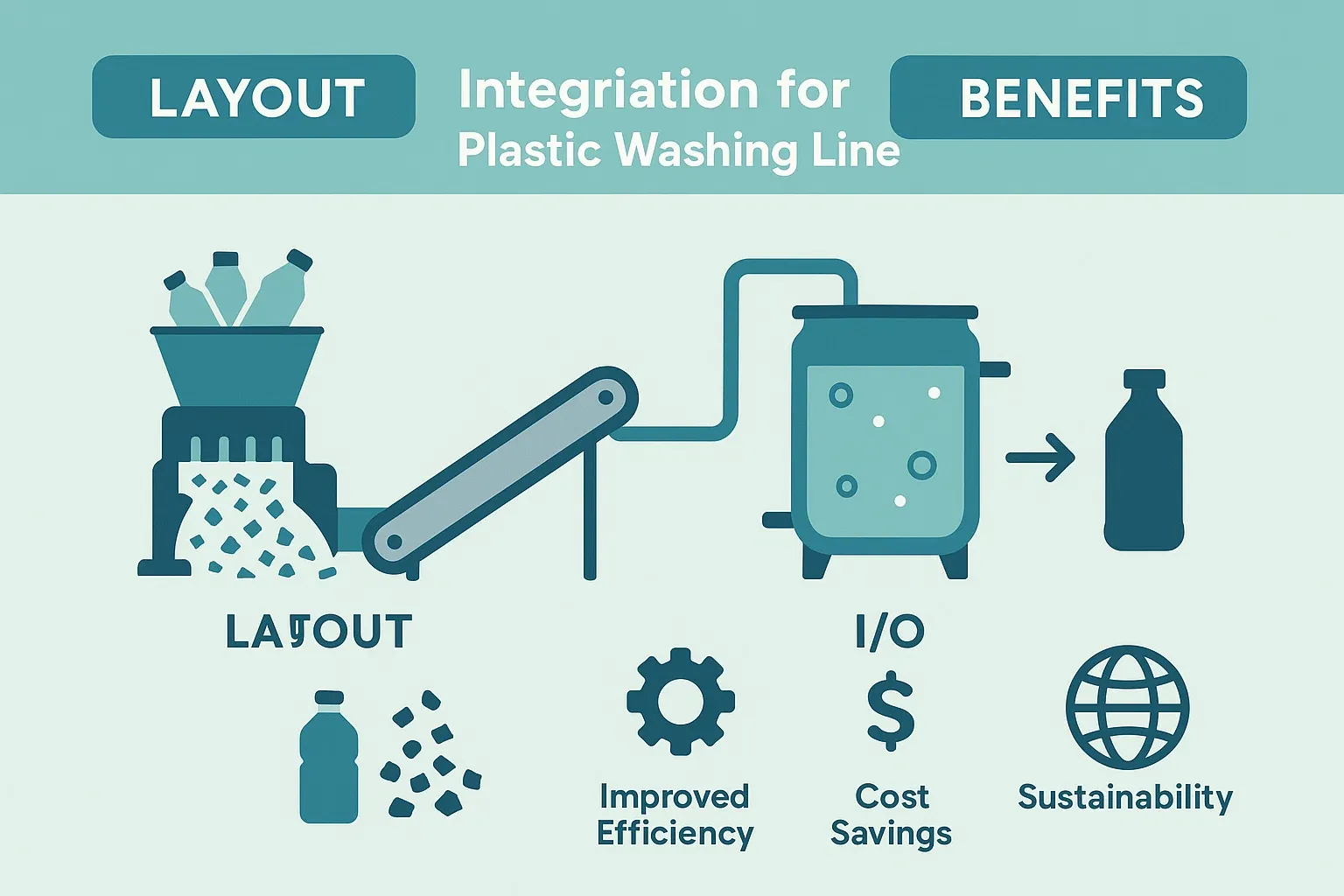

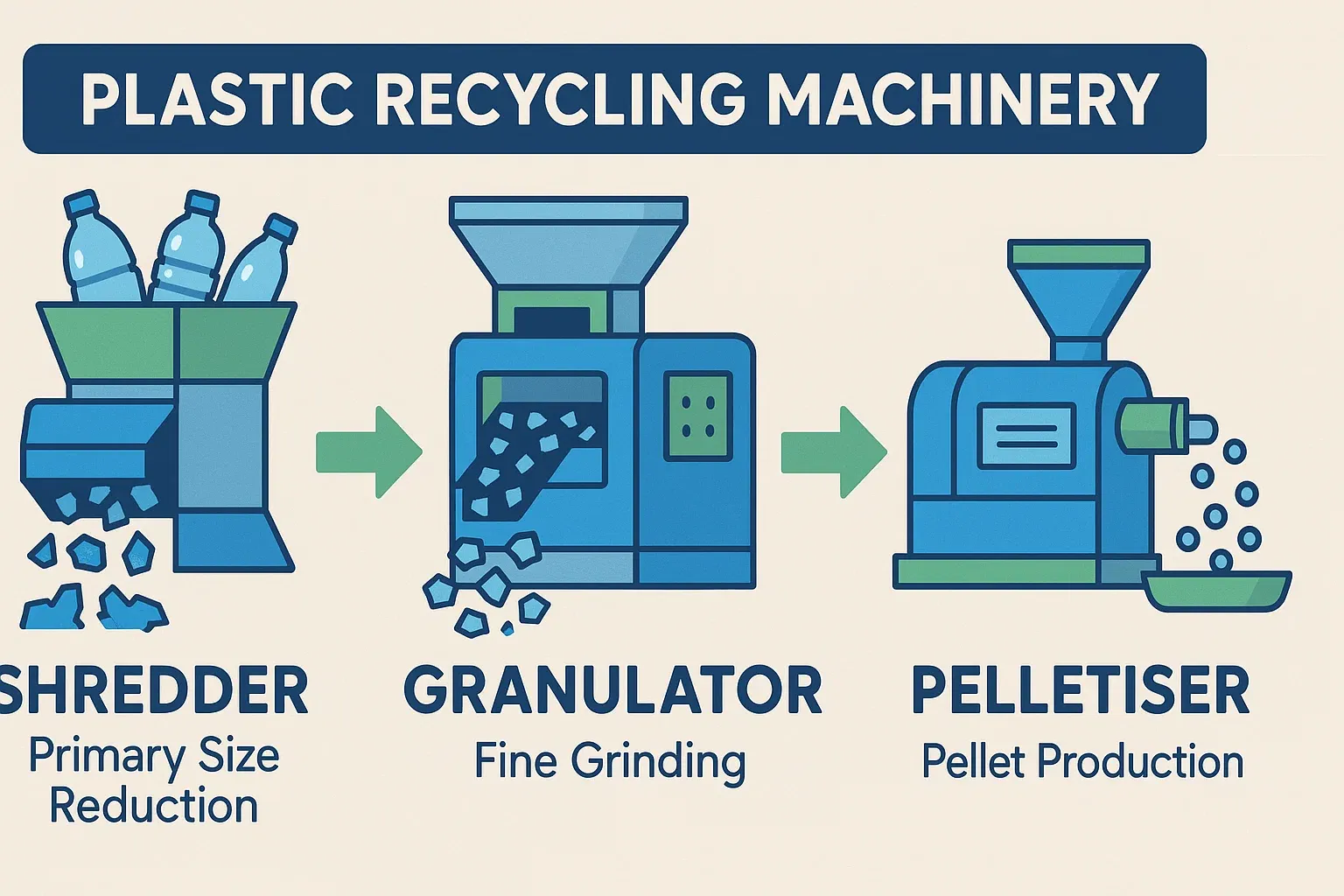

Specialized Shredders for Dirty Films

Standard granulators fail on contaminated films because material wraps or floats. Single-shaft shredders with high-torque motors cut through sandy, oily LDPE cleanly. These machines feature reinforced blades and screens that resist wear from abrasives. Learn more about specialized shredders for film recycling on our guide.

Densifiers and Squeezers for Volume Reduction

After shredding, densifiers or squeezers compress fluffy flakes into dense granules. This step removes air and residual moisture while achieving compression ratios up to 50:1. The result: easier feeding into extruders and lower transport costs. See details on plastic film squeezers and density gains.

High-Output Extruders and Pelletizers

Twin-screw or single-screw extruders with strong filtration systems melt and clean the material. Multiple screen changers catch sand and contaminants before pelletizing. Water-ring or strand pelletizers then produce uniform pellets suitable for resale or reuse.

All Energycle systems run on standard U.S. industrial power: 480V, 60Hz, 3-phase. This compatibility means no costly transformers or rewiring when you install in Texas facilities.

Step-by-Step Guide to Set Up Your LDPE Film Processing Line

Follow these practical steps to process dirty post-consumer LDPE films effectively:

- Collect and Sort → Bale films on site and separate obvious non-plastics like metal straps.

- Shred → Feed bales into a high-torque shredder to create uniform pieces.

- Densify → Run shredded material through a squeezer or agglomerator to boost density and remove moisture.

- Extrude and Filter → Melt the densified material and push it through fine screens to remove contaminants.

- Pelletize and Cool → Cut hot strands or die-face pellets and cool them for packaging.

This mechanical approach produces pellets with melt indexes suitable for film blowing or molding. Many Texas operators achieve payback in 12 to 24 months through avoided disposal fees and pellet sales.

Real Benefits for Texas Energy Companies

Facilities that invest in high-capacity lines gain control over waste streams. You reduce landfill costs, meet sustainability goals, and create a new revenue source from pellets. The U.S. Environmental Protection Agency notes that mechanical recycling conserves energy and reduces emissions compared to virgin resin production.

The American Chemistry Council reports growing demand for post-consumer resins in packaging applications.

Texas energy operators also benefit from local support and equipment designed for American power standards. Energycle systems stand up to the sandy, oily conditions common in Permian Basin and Eagle Ford operations.

Ready to process your post-consumer LDPE films at scale? Contact Energycle for a custom line consultation built for Texas energy needs. Explore our LDPE film densification solutions or complete pelletizing guide to get started.

External resources:

A "Jack of all trades" shredder is a master of downtime. While it is tempting to buy one machine to process "everything" (Purging, Film, Pipe, Pallets), the physics of material reduction dictate that you will lose 30-40% efficiency on every ton. This guide explains why specialization is the only path to profitability.

Related equipment: PE/PP film shredder, rigid plastic shredder.

1. The RPM Mismatch

- Film/Fiber (Soft): Requires High Torque + High Speed (80-100 RPM). You need momentum to shear the material before it stretches.

- Hard Plastic (Lumps): Requires High Torque + Low Speed (40-60 RPM). High speed causes the rotor to bounce off the block, creating shock loads.

- The "Universal" Compromise: A machine running at 70 RPM is too fast for lumps (shock) and too slow for film (jamming).

2. Rotor Geometry: Spline vs. Smooth

- Film/Fiber: Often uses an Anti-Winding Spline Rotor. The raised surfaces prevent the material from lying flat and wrapping.

- Rigid Plastic: Uses a Smooth Rotor. Splines would create stress concentration points that could crack when hitting a solid block of PP.

- Result: Running film on a smooth rotor often leads to wrapping. Running dense lumps on a spline rotor can increase stress concentrations and risk mechanical damage, depending on rotor design and control settings.

3. Ram Logic (Hydraulics)

- Film: Light and fluffy. Requires a Turbo Ram (fast approach, low pressure) to constantly force material into the blades.

- Pipe/Purging: Dense and solid. Requires a Load Sensing Ram (slow approach, high pressure) that "nibbles" the material to prevent stalling.

- Conflict: A universal ram logic will either overfeed the lumps (stall) or underfeed the film (throughput drop).

4. Screen Design

- Film: 40mm screen with 50% Open Area.

- Rigid: 40mm screen with 35% Open Area (stronger web thickness).

- Failure: Running lumps on a film screen will bend or break the screen due to lack of structural rigidity.

Conclusion

Buying two specialized machines (one for film, one for rigid) often has a lower Total Cost of Ownership (TCO) than buying one "Universal" machine that runs at 60% efficiency and requires constant maintenance.

References

[1] "Efficiency in Plastic Recycling," Waste Management World. Efficiency in Plastic Recycling

[2] "Design Principles of Industrial Shredders," Journal of Engineering. Design Principles of Industrial Shredders

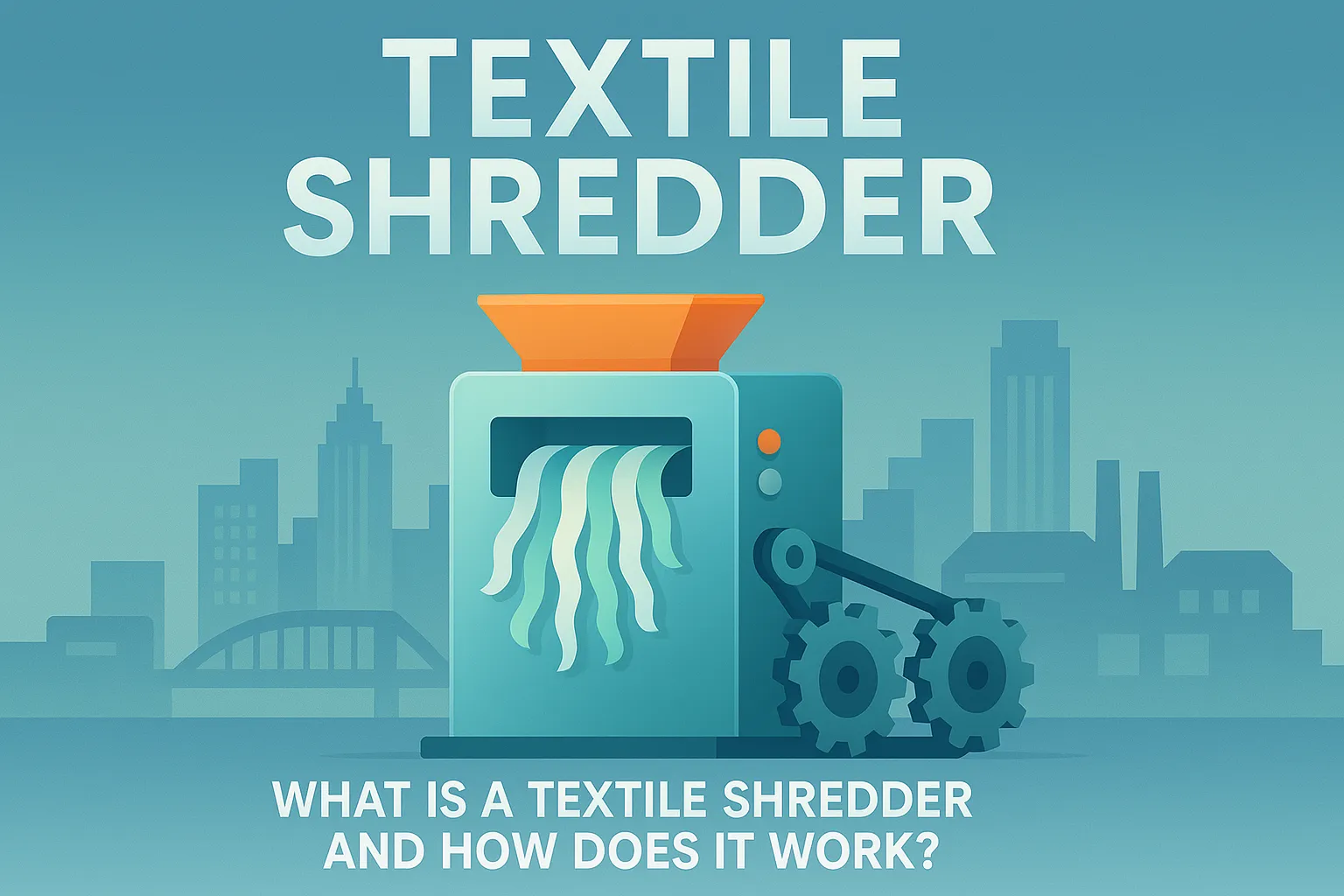

Shredding textile waste is mechanically different from shredding plastic. A plastic bottle cracks; a cotton shirt stretches. In many textile applications, the machine performs best when configured to Shear rather than Tear. This guide explains the rotor geometries required for high-volume textile recovery.

Related equipment: textile waste single shaft shredder.

1. The Enemy: Winding (Wrapping)

Textiles are high-tensile materials. If the knife dulls or the gap is too wide, the fabric will not cut—it will wrap around the rotor shaft, eventually stalling the motor or burning out the bearings.

The Solution: The "Splined" Anti-Winding Rotor

Standard rotors are smooth cylinders. Textile rotors typically use Raised Splines or Wear Strips welded between the knife holders.

* Function: These raised areas prevent long strips of fabric from lying flat against the shaft, breaking the surface tension and preventing tight wrapping.

* Protection: Bolt-on Winding Discs at the rotor ends protect the bearing housing seals from fiber ingress.

2. Cutting Geometry: The "Double Scissor"

Straight cut knives act like a guillotine—high impact, high noise.

* V-Rotor (Chevron): Knives are arranged in a "V" shape.

* Effect: Pulls material toward the center of the rotor, preventing it from jamming against the side walls.

* F-Rotor (Fillet): Knives are arranged in a continuous spiral.

* Effect: Only 1 knife cuts at a time. Constant load, lower amperage spikes, smoother operation on heavy carpets.

3. Throughput Calculation Logic

Textile waste has incredibly low bulk density (60 - 100 kg/m³).

* Formula: $Capacity (kg/h) = Volume (m³) \times RPM \times Efficiency \times Density$.

* Implication: You need a physically larger machine to achieve the same tonnage as plastic.

* Example: A 1200mm shredder does 2 tons/hr of plastic. It will only do 600 kg/hr of loose textile.

* Fix: Hydraulic Ram Assist. A customized "High Speed" ram is required to force the fluffy material into the rotor to artificially increase density at the cutting point.

4. Application-Specific Output

- Rag Production (Wiping): 100mm - 150mm strips. Requires a large screen (100mm).

- Fiber Opening (Recycling): <40mm chips. Requires a small screen (40mm) and high rotor speed (120 RPM) to "open" the weave.

References

[1] "Mechanics of Fiber Cutting," Textile Research Journal. Mechanics of Fiber Cutting

[2] "Design of Industrial Shredders," Waste Management. Design of Industrial Shredders

The textile recycling industry is shifting from "downcycling" (insulation/rags) to "circularity" (fiber-to-fiber). This shift demands a radical change in shredding technology. A machine that makes rags cannot prepare feedstock for a chemical depolymerization reactor. This guide explores the pre-processing innovations required for modern textile recovery.

Related equipment: textile waste single shaft shredder.

1. The Feedstock Gap: Fluff vs. Chips

Mechanical Recycling (Spinning)

- Goal: Retain max fiber length (>15mm).

- Technology: Garnett-style single-shaft shredders with tearing pins.

- Innovation: Soft-Start High-Torque Drives that gently pull fabrics apart at low speeds (<60 RPM) to minimize fiber breakage and friction heat (which melts Polyester).

Chemical Recycling (Depolymerization)

- Goal: Maximize surface area for chemical reaction.

- Requirement: Uniform, dense "chips" (e.g., 10mm x 10mm). Fluff causes "bridging" in hoppers and floats in solvents.

- Technology: Double-Cut Granulators. A secondary granulator with a "guillotine" rotor cuts the pre-shredded textile into precise squares, increasing bulk density from 40kg/m³ to 150kg/m³.

2. Automated Sorting (NIR)

You cannot rely on garment labels (they are often wrong).

* Innovation: Hyperspectral NIR Cameras mounted over the shredder infeed conveyor.

* Function: Detects the precise Polyester/Cotton ratio (e.g., 60/40 vs 50/50) in milliseconds.

* Action: Air jets divert non-compliant items (e.g., all-nylon items in a cotton line) before they enter the shredder.

3. The "Hard Part" Problem: Zippers & Buttons

Zippers (Brass/Alu) and Buttons (Thermoset Plastic) destroy fine shredder blades.

* Old Method: Manual removal (too expensive).

* New Method: Hammer Mill Liberation.

* After pre-shredding to 50mm, the textile is passed through a high-speed Hammer Mill.

* The impact shatters buttons and detaches zippers from the fabric.

* A downstream Eddy Current Separator and Zig-Zag Air Classifier then remove the heavy metal/plastic fragments, leaving pure fiber.

4. Dust Control: The Microfiber Threat

Polyester microfibers are explosive (Kst > 0) and a respiratory hazard.

* Innovation: Negative Pressure Cutting Chambers.

* The shredder rotor is enclosed in a vacuum-sealed housing.

* Dust is extracted at the source (the cutting point) rather than allowing it to float into the room.

* This improves sensor reliability (no dust on optical lenses) and prevents cross-contamination of colors.

Conclusion

The future of textile recycling is not just "shredding"—it is fractionation. Buying a general-purpose shredder for sophisticated textile recovery often produces inconsistent feedstock and poor downstream yields. You should engineer the line for your specific end-product: Fiber (Mechanical) or Monomer (Chemical).

References

[1] "Guide to Recycled Materials (GRS-202)," Textile Exchange. Guide to Recycled Materials (GRS-202)

[2] "Automated Sorting Technologies," Recycling International. Automated Sorting Technologies