Recycling News

Categories buying-guides, Recycling News

Posted on

Learn the key differences between plastic shredders and crushers for recycling. This guide explains operational principles, output sizes, and buyer decision strategies — helping professionals choose the best equipment for their waste stream. Find custom machine details and actionable tips with Energycle Machine.

Categories buying-guides, Recycling News

Posted on

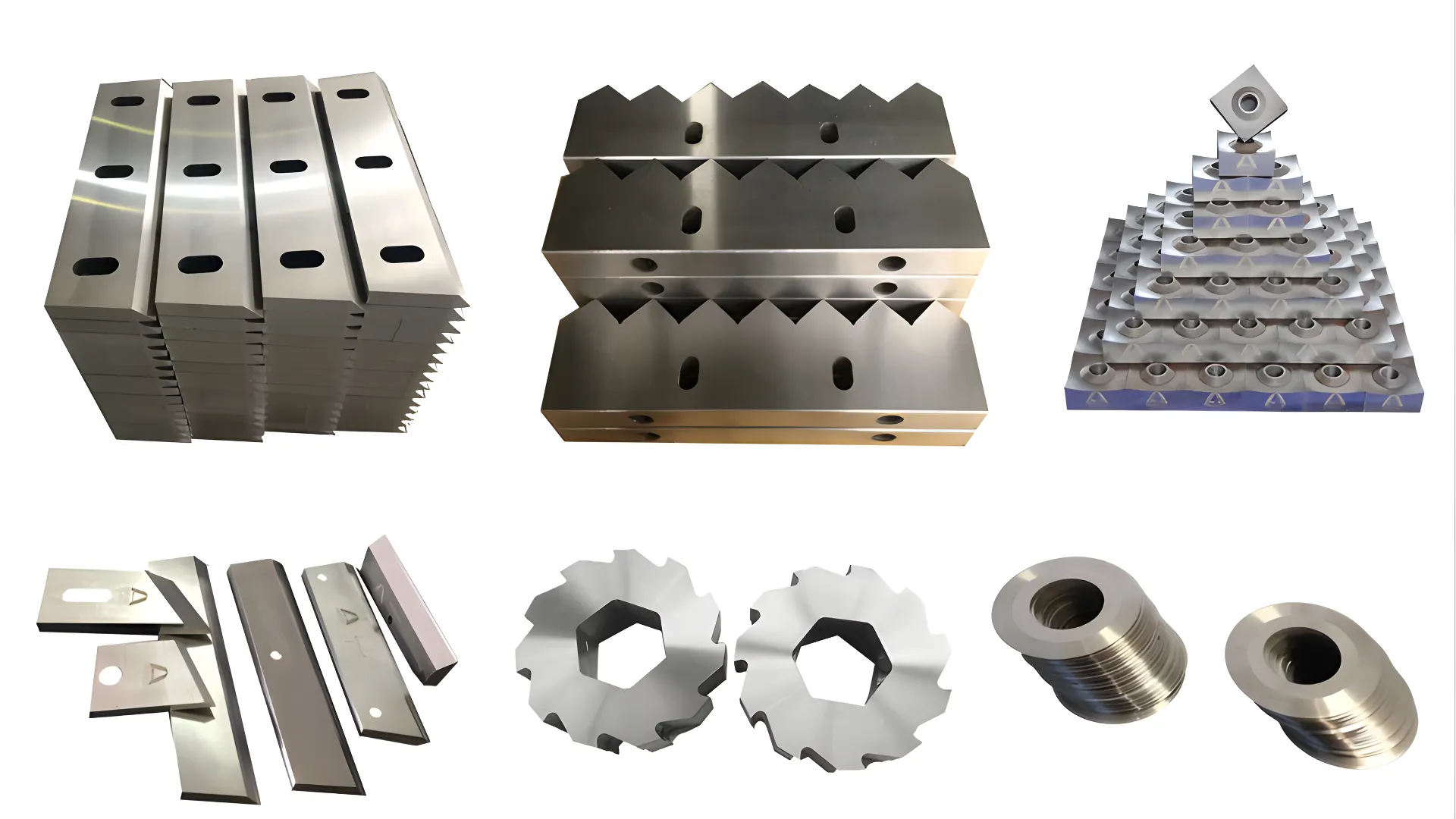

This article provides a comprehensive overview of shredder blades, detailing their importance in the shredding process and the steps involved in their manufacturing. It offers valuable insights into selecting the right materials and adhering to processing standards to ensure longevity and performance of the blades.

Categories buying-guides, Recycling News

Posted on

Discover why D2 and SKD-11 steels, enhanced with tungsten-carbide coatings, are the go-to choices for durable shredder knives. This guide explains key material properties, wear-resistance advantages, and maintenance tips that help engineers and buyers keep their shredding lines running longer and leaner.

Categories buying-guides, Recycling News

Posted on

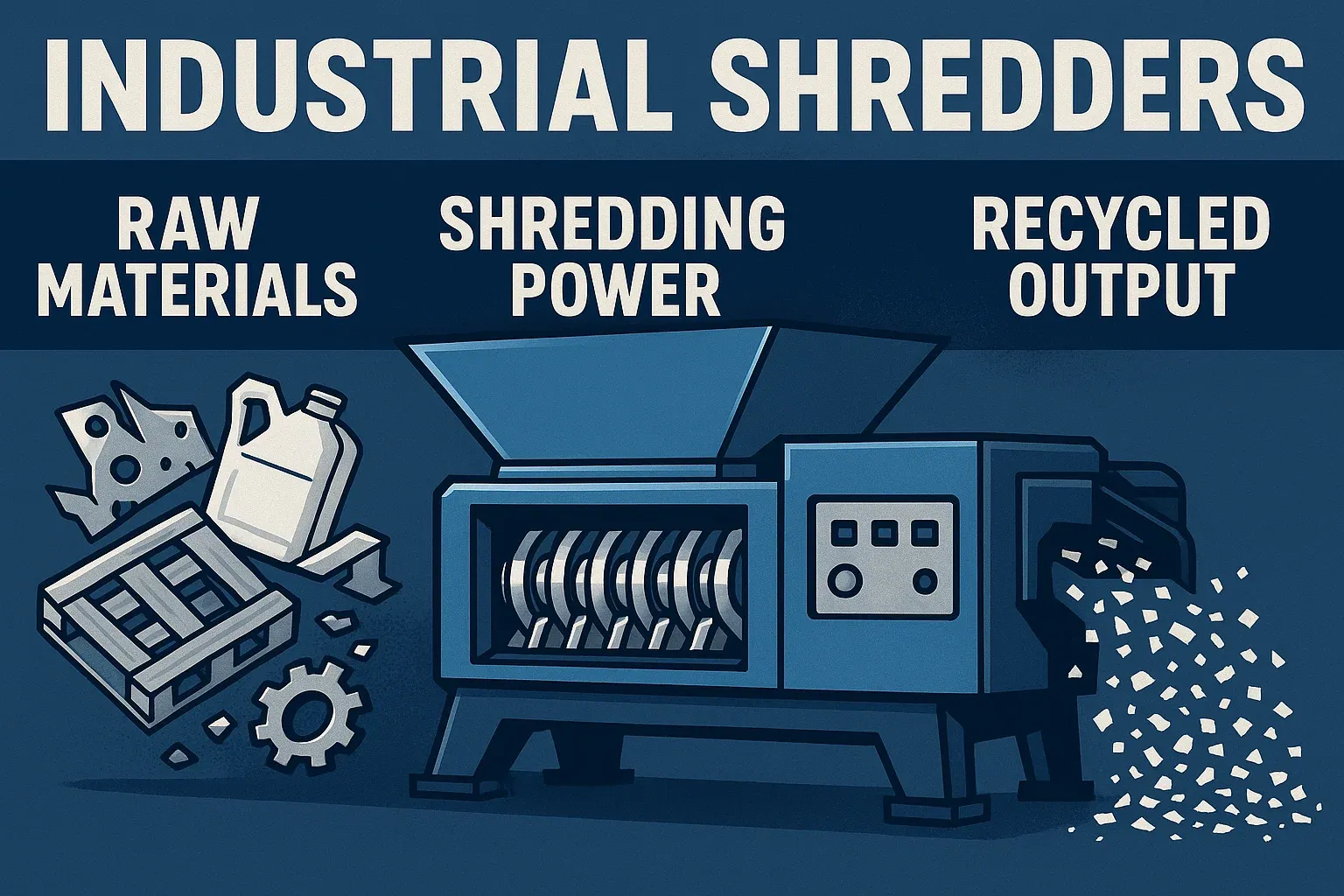

Learn about industrial shredders, their operation principles, different types, and applications in recycling and waste management.

Categories buying-guides, Recycling News

Posted on

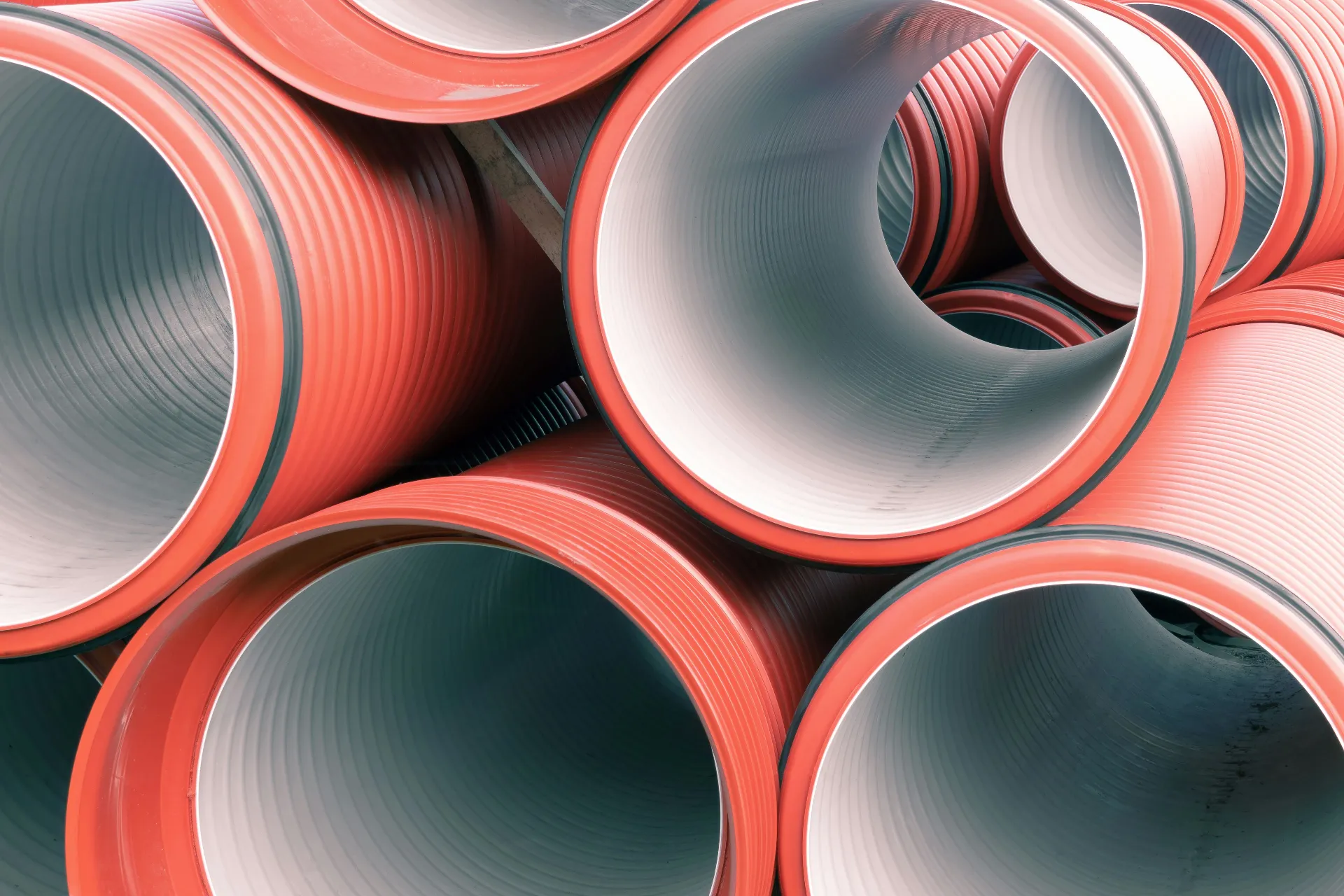

Selecting the ideal PVC pipe shredder is crucial for efficient plastic waste management and recycling. This guide breaks down the essential factors to consider, from motor power and blade quality to capacity, durability, safety features, and cost-effectiveness, ensuring you choose a machine that meets your specific operational needs and delivers a strong return on investment.

Categories buying-guides, Recycling News

Posted on

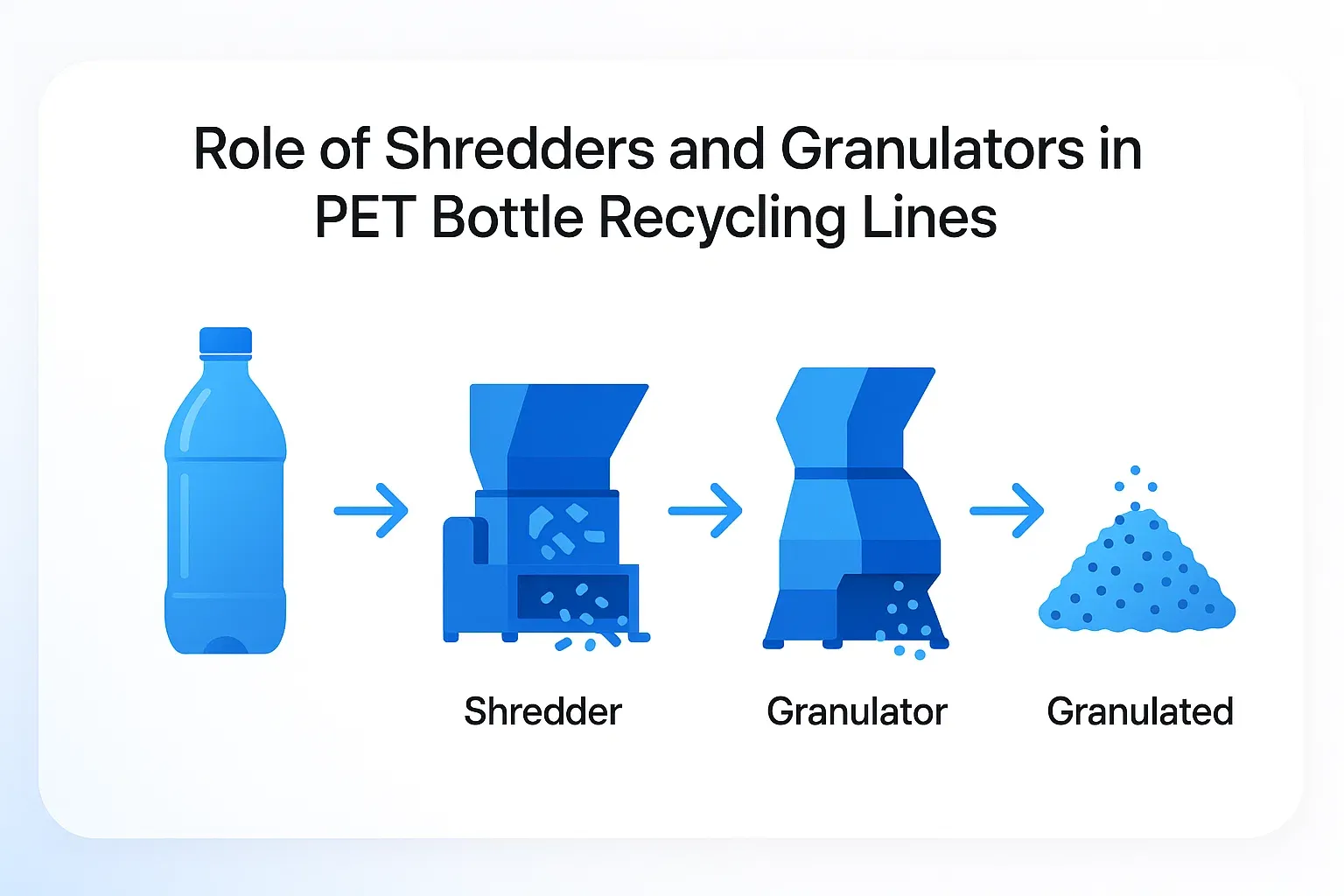

Unlock efficient PET bottle recycling! Explore the essential roles of shredders and granulators in transforming waste bottles into valuable rPET flakes. Understand their differences, benefits, and selection criteria for your recycling line. A must-read for industry professionals.

Categories buying-guides, Recycling News

Posted on

Transporting hollow pipes to recycling centers is a logistical nightmare that burns fuel and profits. The mobile pipe shredder changes the game by bringing industrial-grade crushing power directly to the job site. Discover how on-site shredding reduces volume, cuts costs, and streamlines your plastic recycling operations with Energycle’s advanced solutions.

Categories buying-guides, Recycling News

Posted on

Industrial shredders are essential machines for recycling and manufacturing operations. This practical guide explains how industrial shredders work, the main shredder types, typical applications, and how to select the right shredder based on material, capacity, and downstream processing requirements.

Categories buying-guides, Recycling News

Posted on

Discover how to navigate EU CE and US OSHA compliance for industrial plastic shredders. This guide covers regulations, safety features, and practical tips to ensure safe, efficient operations for engineers and equipment purchasers.

Categories buying-guides, Recycling News

Posted on

Hard drive shredders offer a secure solution for data destruction, physically destroying drives and making recovery impossible. This article explores the advantages, working principles, and applications of hard drive shredders.

Categories buying-guides, Recycling News

Posted on

HDPE pipes' impressive durability presents unique recycling challenges. This guide explores why specialized pipe shredders are essential for effectively breaking down these tough materials, optimizing the recycling workflow, and contributing to a more sustainable future. Learn how the right equipment makes all the difference.

Categories buying-guides, Recycling News

Posted on

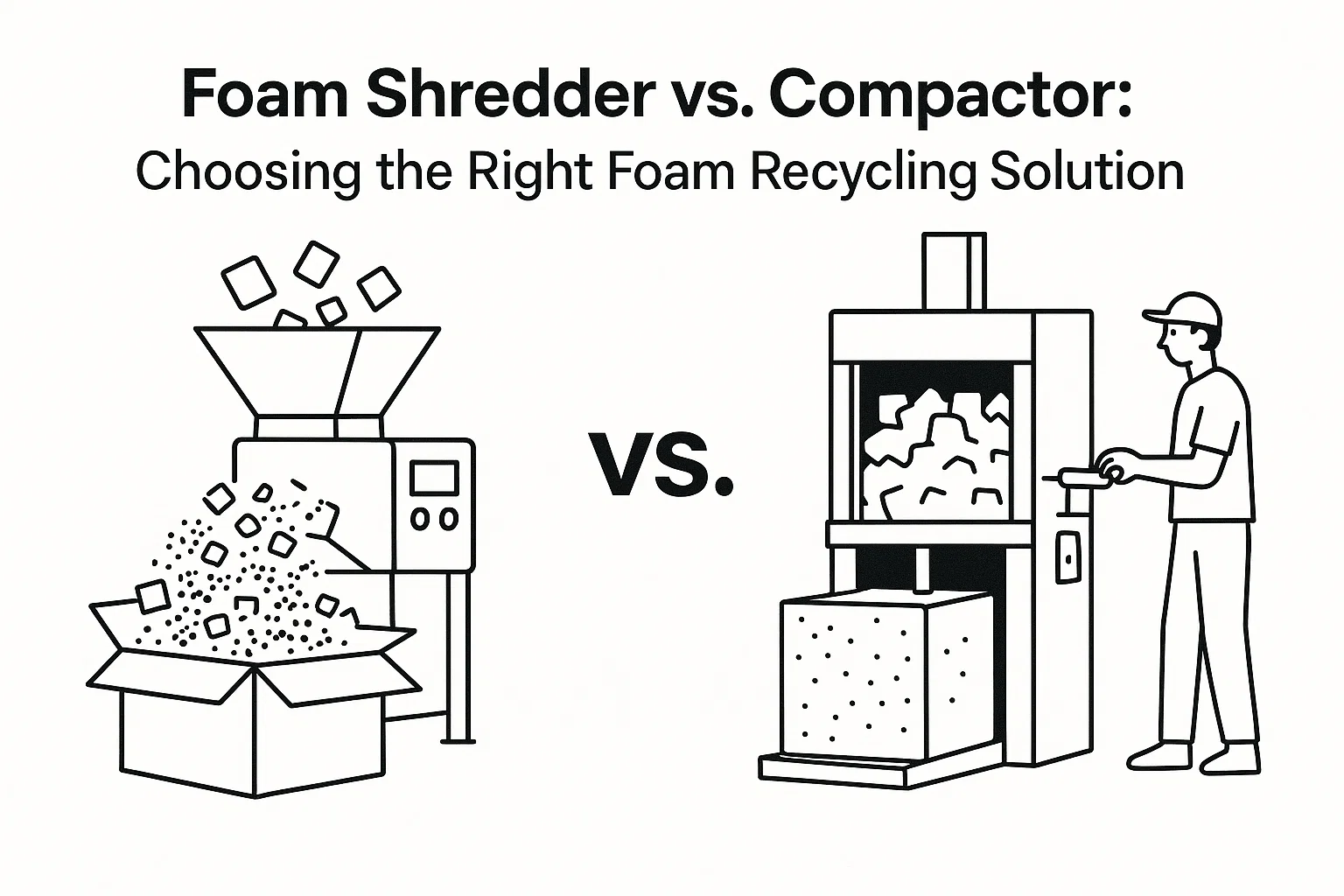

Understand the distinct roles of foam shredders and compactors in foam recycling. A shredder reduces piece size for reuse as filler, while a compactor drastically reduces volume for transport and sale. This guide helps you choose the right machine based on your business goals, foam type, and volume.