Recycling News

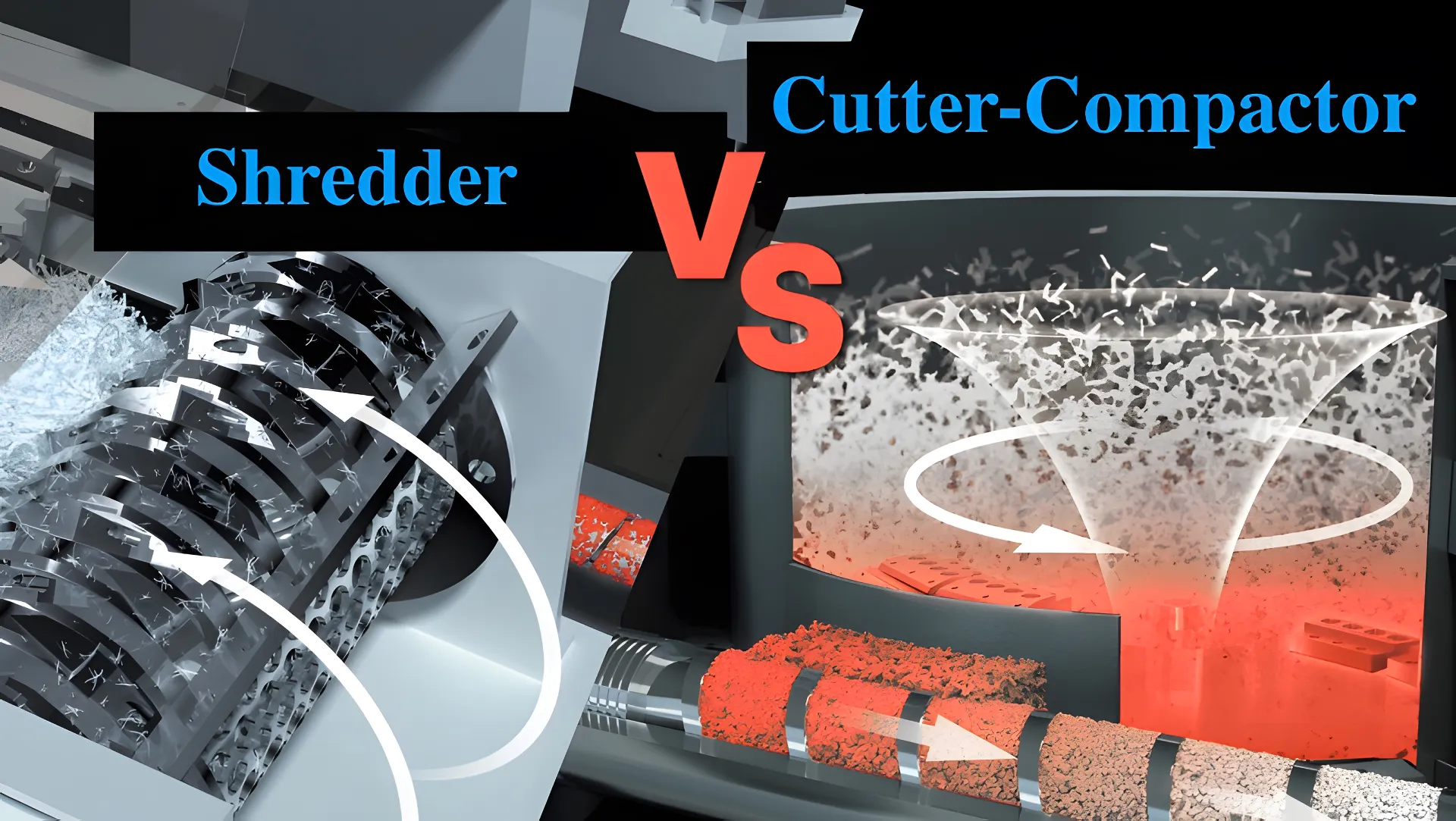

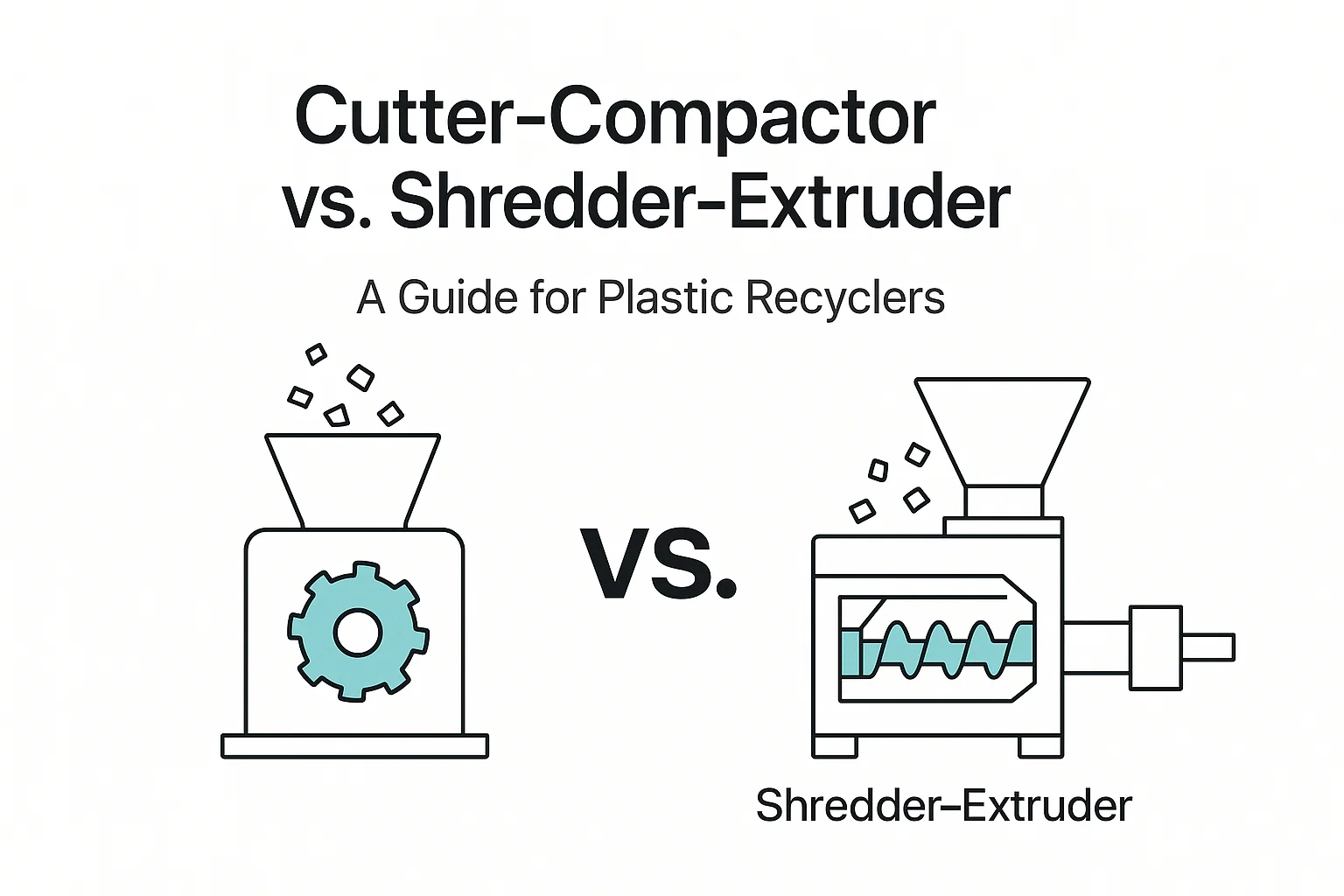

In industrial plastic recycling, the choice between a Cutter-Compactor system (often called the "3-in-1") and a standard Shredder-Extruder combination defines your plant's efficiency. While both reduce size, their thermodynamic impact on the material differs fundamentally.

- Cutter-Compactor systems use friction to densify and pre-heat light materials.

- Shredder-based systems rely on high-torque cold cutting for dense, rigid inputs.

This engineering guide compares the two technologies based on moisture tolerance, bulk density, and material morphology.

Related equipment: extruder lumps shredder, PE/PP film shredder.

The Cutter-Compactor: Densifying Light Fractions

The Cutter-Compactor (integrated into machines like the Energycle Compact Series) features a large pot at the base of the extruder. Rotating blades cut the plastic while generating significant friction heat.

Best For:

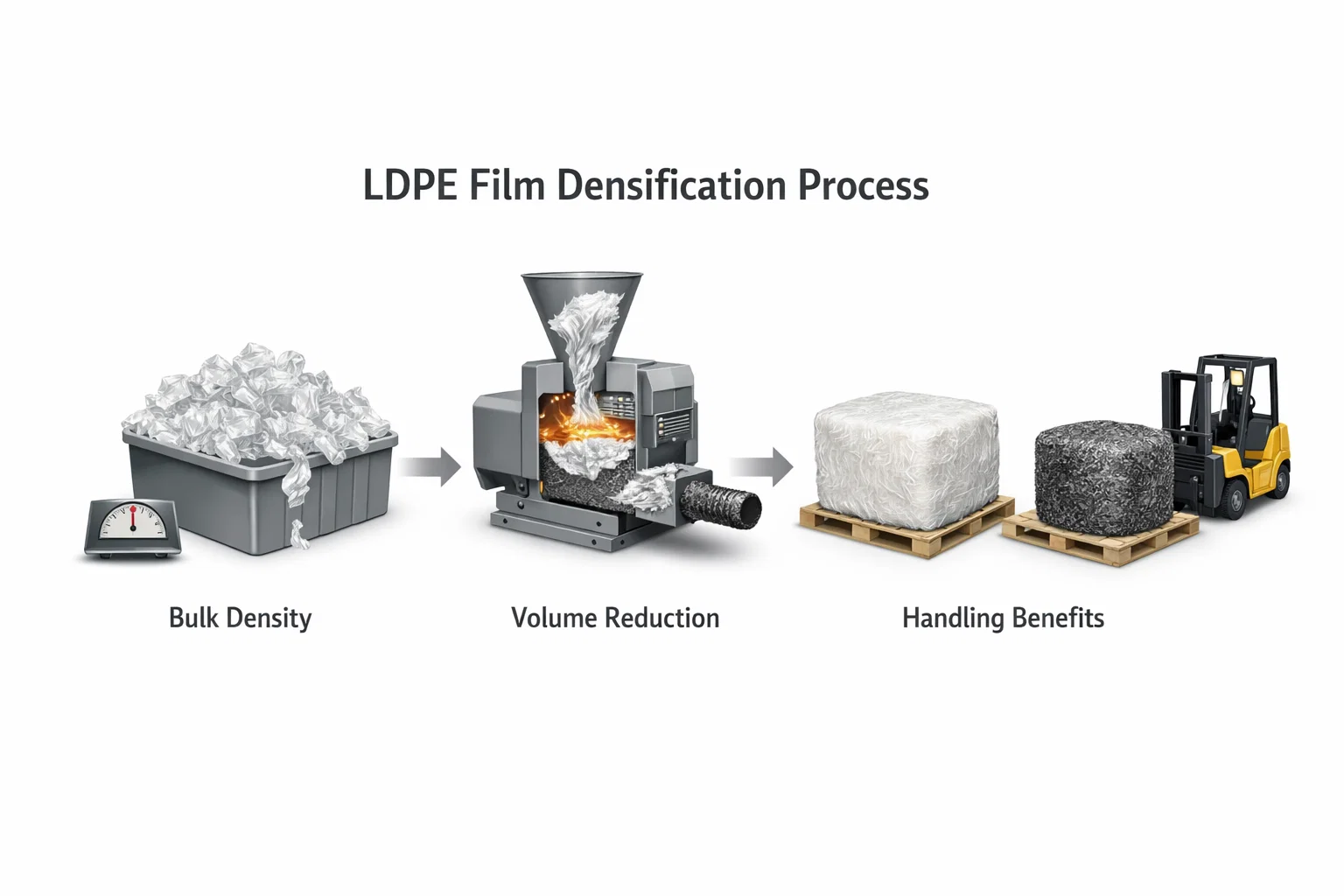

- Film & Raffia: LDPE agricultural film, PP woven bags, and stretch wrap with low bulk density (approx. 50-100 kg/m³).

- Wet Material: The friction heat (up to 100°C) effectively flashes off surface moisture (up to 5-7%), acting as a pre-dryer.

- Washed Flakes: Ideal for processing thin flakes that need to be stabilized before entering the screw.

The Mechanism

- Cutting: Rotors shear the film against stationary knives.

- Compaction: Centrifugal force presses the material against the wall, increasing density.

- Heating: Friction warms the polymer near its Vicat softening point.

- Dosing: The semi-molten material is tangentially fed into the extruder screw at a constant rate, ensuring high output stability.

The Shredder-Extruder: Crushing Rigid Inputs

A Shredder-Extruder system couples a heavy-duty single-shaft shredder directly to the extruder. This "cold" process relies on mechanical torque rather than thermal friction.

Best For:

- Rigid Plastics: HDPE pipes, purging lumps, car bumpers, and thick pallets.

- Heavy Contamination: Sand/Paper contamination is better handled by low-speed rotors than high-speed compactor blades (which dull quickly).

- Heat-Sensitive Material: Sensitive polymers (like heavily printed BOPP) generally degrade less in a cold shredder than in a hot compactor pot.

The Mechanism

- Shredding: A hydraulic ram forces material into a slow-rotating rotor (approx. 80 RPM).

- Sizing: Material passes through a screen (e.g., 40mm) to ensure uniform size.

- Feeding: The cold chips drop directly into the extruder throat or onto a conveyor.

- Extrusion: The screw does most of the melting work (with the balance coming from barrel heating and process losses).

Decision Matrix: Which Machine Do You Need?

| Parameter | Cutter-Compactor Line | Shredder-Extruder Line |

|---|---|---|

| Input Density | Low (< 150 kg/m³) - Film, Foam, Fiber | High (> 200 kg/m³) - Hard Regrind, Parts |

| Moisture Tolerance | High (5-7%) - Friction drying | Low (< 2%) - Needs pre-drying |

| Pre-Heating | Yes (Pre-conditions material) | No (Cold feed) |

| Energy Profile | Higher (Compactor motor + Extruder) | Lower (Mechanical cutting only) |

| Printed Ink | Heavy degassing required (ink vaporizes) | Less vaporization at entry |

| Maintenance | Blade sharpening (Critical) | Rotor Knife Rotation (Periodic) |

Conclusion

Select a Cutter-Compactor if your primary feedstock is lightweight, washed film, or woven fiber. The ability to densify and dry in a single step makes it the industry standard for post-consumer film recycling.

Select a Shredder-Extruder if you process rigid plastics, hard lumps, or heat-sensitive engineering polymers. Its robust torque handles heavy objects that would stall or damage a compactor's high-speed blades.

Energycle offers both configurations, allowing engineers to tailor the intake module specifically to the waste stream's morphology.

References

[1] "Plastics — Guidelines for the recovery and recycling of plastics waste (ISO 15270:2008)", ISO. Plastics — Guidelines for the recovery and recycling of plastics waste (ISO 15270:2008)

[2] Techno-Economic Analysis (TEA) overview resources, NREL. NREL

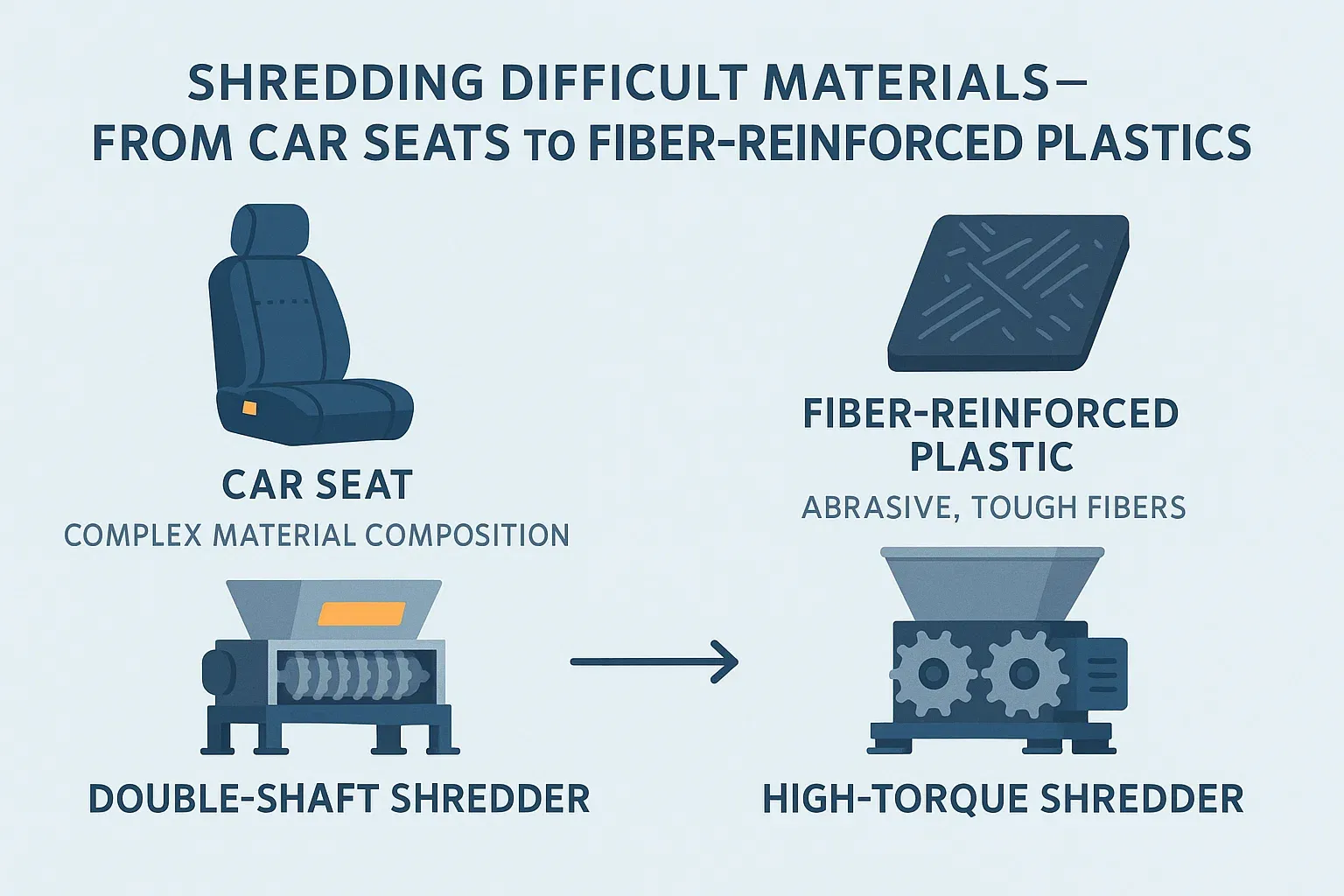

Post-consumer carpet is the "nemesis" of standard shredders. While the face fiber (Nylon, PP, or PET) is tough, the real killer is the backing. Often heavily filled with Calcium Carbonate (CaCO3) and contaminated with grit, carpet backing can act like a flexible grinding stone, dulling tool steel blades quickly (sometimes in tens of operating hours). This guide engineers a solution for high-volume carpet processing.

Related equipment: textile waste single shaft shredder.

The Chemistry of Wear: Why Blades Fail

Most industrial shredders use D2 or Cr12MoV steel (Hardness: 58-60 HRC).

* The Problem: Calcium Carbonate is soft (Mohs 3), but the sand/silica impurities often found in post-consumer carpet are hard (Mohs 7).

* The Result: Rapid abrasive wear. A standard blade set costing \$3,000 might last only 2 weeks in a 24/7 carpet line.

The Solution: Carbide-Tipped Knives

To process carpet economically, Tungsten Carbide inserts are often justified when backing abrasion and grit drive frequent knife changes.

* Hardness: 90+ HRC (virtually wear-proof against CaCO3).

* Design: A steel carrier with a brazed carbide tip.

* Cost vs. Life: Often costs several times more than D2, but can last several times longer in abrasive service.

* ROI: Downtime savings can pay for the upgrade quickly, but the payback depends on uptime, blade change labor, and contamination level.

High-Tensile Fibers: The "Winding" Risk

Nylon 6,6 face fibers are engineered not to break. When shredded, long loose strands tend to wrap around the rotor shaft, eventually burning out the bearings.

Required Machine Features:

1. Splined "Anti-Winding" Rotor: A textured shaft surface prevents fibers from slipping and tightening.

2. Close-Tolerance Cutting Gap: The gap between rotor and stator is often specified at $<0.5mm$ (depending on knife condition and rotor design). If the gap is 1.0mm, the nylon will simply fold over the blade instead of cutting, leading to a jam.

3. Shaft Protection Plates: Physical labyrinth seals bolted to the rotor ends to stop fiber migration into the bearing housing.

Application: Fuel vs. Fiber Recommendation

1. Waste-to-Energy (Cement Kilns)

- Goal: High BTU fluff for co-processing.

- Specification: <30mm particle size. Separation of calcium carbonate is less critical as it becomes part of the cement clinker.

- Machine: Heavy-Duty Single Shaft Shredder with Carbide Knives.

2. Closed-Loop Recycling (Depolymerization)

- Goal: Pure Nylon 6 or 6,6 Face Fiber.

- Process: Shredding -> Hammer Mill -> Density Separation.

- Machine: You need a "Shear Shredder" first to liberate the face fiber from the backing without pulverizing the glue, aiding downstream separation.

Operating Protocol for Carpet Rolls

Never feed a whole roll of broadloom carpet into a shredder unless it is a 100+ unit (100 HP / 75 kW minimum). The density of a tightly wound roll can stall a smaller rotor instantly.

* Best Practice: Use a Guillotine Shear to chop rolls into 1-meter "pucks" before feeding, or unwind the roll using a specialized feeder.

FAQ

Can I recycle car mats?

Automotive carpet is often PET with a heavy rubber/bitumen backing. It is even more abrasive than residential carpet. Carbide is mandatory.

Why is my shredder overheating?

Dull blades cause friction. In carpet, this friction melts the PP backing (melting point ~160°C). If you see "plastic lava" on your rotor, your blades are dull.

References

[1] "Carpet Abrasiveness Study," Recycling Technology Today. Carpet Abrasiveness Study

[2] "Nylon 6,6 Tensile Properties," DuPont Engineering Polymers. Nylon 6,6 Tensile Properties

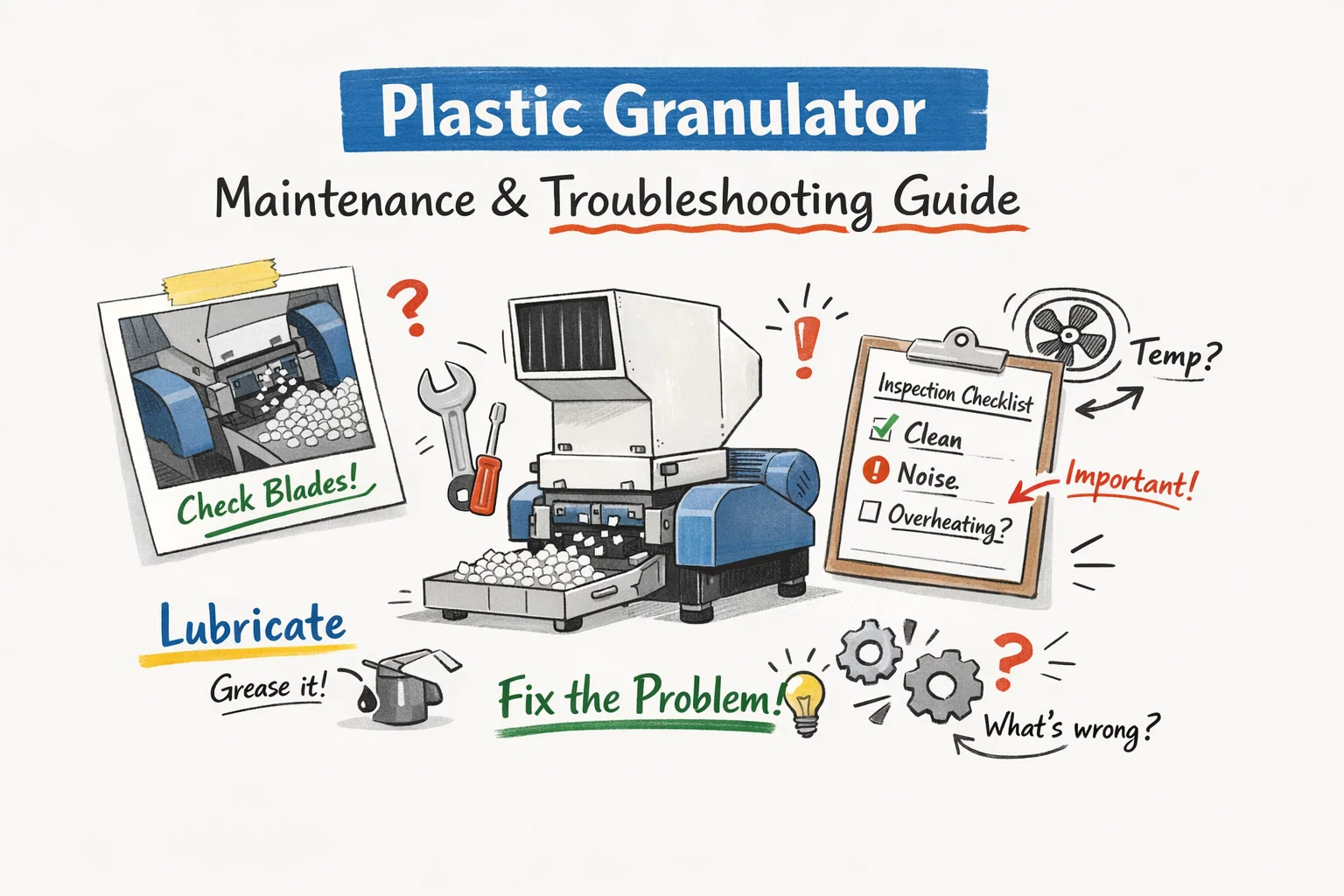

Plastic granulators are a critical part of daily operations in recycling plants, responsible for reducing plastic waste into uniform granules for downstream processing. Over time, however, wear, contamination, and improper operation can significantly reduce performance and increase downtime.

This guide focuses on practical maintenance, troubleshooting, and operational best practices to help recycling facilities extend service life, maintain stable output, and reduce unplanned shutdowns—without overlapping with equipment selection or purchasing decisions.

Why Proper Granulator Maintenance Matters in Recycling Plants

In continuous recycling operations, a plastic granulator is exposed to variable materials, abrasive contaminants, and high mechanical loads. Without a structured maintenance routine, even well-designed machines can suffer from premature wear and declining performance.

Effective maintenance helps to:

- Maintain consistent granule quality during long production runs

- Reduce unexpected stoppages and emergency repairs

- Extend the operational lifespan of wear components

- Improve overall plant efficiency and safety

For recycling facilities operating on tight margins, preventive maintenance is often more cost-effective than reactive repairs.

Essential Plastic Granulator Maintenance Tasks

A structured maintenance schedule ensures stable operation under real recycling conditions. The following tasks are recommended for most industrial recycling environments.

Daily Maintenance

- Clean the hopper and feeding area to prevent material buildup

- Inspect the cutting chamber for residual plastic or contamination

- Check blades and screens for early signs of wear

- Verify lubrication points according to operating hours and load

Weekly Maintenance

- Clean air filters to maintain proper cooling and airflow

- Inspect drive belts and couplings for tension and alignment

- Check electrical connections for looseness or overheating

- Remove dust accumulation from external surfaces

Monthly Maintenance

- Verify rotor and stator alignment under operating conditions

- Inspect bearings for abnormal noise or temperature rise

- Clean and lubricate the gearbox if applicable

- Test safety systems such as emergency stops and interlocks

Annual or Scheduled Overhaul

- Replace high-wear components such as blades, screens, and bearings

- Inspect structural elements for fatigue or cracking

- Recheck machine calibration to restore cutting efficiency

- Review operating logs to identify recurring issues

Troubleshooting Common Plastic Granulator Problems

Even with regular maintenance, operational issues may still occur. Early diagnosis can prevent minor problems from escalating.

Granulator Will Not Start

- Confirm stable power supply and correct voltage

- Inspect safety switches and interlocks

- Ensure the emergency stop circuit is fully reset

Reduced Output or Throughput

- Check blade sharpness and cutting gap

- Inspect screens for clogging or deformation

- Verify that feed material size and flow rate are consistent

Inconsistent Granule Size

- Inspect blades and screens for uneven wear

- Confirm proper rotor-to-stator alignment

- Evaluate input material consistency and contamination levels

Excessive Noise or Vibration

- Inspect bearings and mounting points

- Check for rotor imbalance caused by uneven wear

- Ensure the machine is correctly leveled and anchored

Operational Best Practices to Improve Granulator Performance

Beyond routine maintenance, operational discipline plays a major role in long-term performance.

Use Application-Appropriate Blades and Screens

Selecting cutting components that match material type, thickness, and hardness reduces energy consumption and wear.

Maintain a Stable Feeding Process

Sudden surges or inconsistent feeding increase mechanical stress and accelerate blade degradation.

Monitor Energy Consumption Trends

A gradual increase in power draw often indicates blade wear, screen blockage, or bearing issues before visible symptoms appear.

Apply Predictive Maintenance Where Possible

Condition monitoring, vibration analysis, and temperature tracking help identify failures early and reduce unplanned downtime.

When Maintenance Alone Is No Longer Sufficient

Maintenance can extend service life, but it cannot compensate indefinitely for capacity limitations, structural fatigue, or changing production requirements.

If a recycling plant experiences:

- Persistent throughput decline

- Increasing vibration despite repeated repairs

- Structural wear affecting safety or reliability

it may be time to evaluate equipment replacement or system upgrades.

For facilities assessing new solutions, you can review our industrial plastic granulator options here:

https://www.energycle.com/plastic-granulators/

(Single reference for evaluation purposes; maintenance guidance remains equipment-agnostic.)

Conclusion

Plastic granulator maintenance is not simply a checklist—it is an operational strategy that directly affects productivity, safety, and cost control in recycling plants. By combining preventive maintenance, structured troubleshooting, and disciplined operation, recyclers can achieve more reliable performance and longer equipment life.

A clear separation between operational guidance and equipment selection ensures better decision-making at every stage of the recycling process.

Frequently Asked Questions (FAQ)

How often should granulator blades be serviced?

Service intervals depend on material abrasiveness, contamination level, and operating hours. In industrial recycling environments, inspection every 100–300 hours is common.

Are aftermarket parts suitable for recycling operations?

While aftermarket parts may reduce short-term cost, compatibility and durability can vary. Inconsistent parts often lead to faster wear and unstable operation.

How should operators be trained for daily maintenance?

Operators should follow a documented checklist covering cleaning, inspection, and safety verification. Practical training and supervision are essential for consistency.

What should be done in case of sudden failure?

Shut down the machine safely, isolate power, and diagnose the issue systematically. Repeated failures usually indicate deeper mechanical or operational issues.