Recycling News

In today’s world, recycling plastic bottles is not just an environmental necessity but also a smart business strategy. For manufacturers and industrial recycling equipment buyers seeking reliable, efficient solutions, Energycle Machine offers cutting-edge recycling machines designed specifically for plastic bottle recycling. This article explores the technology, benefits, and applications of recycling machines for plastic bottles, highlighting how Energycle Machine stands out as a trusted provider in this vital industry.

Understanding Plastic Bottle Recycling Machines

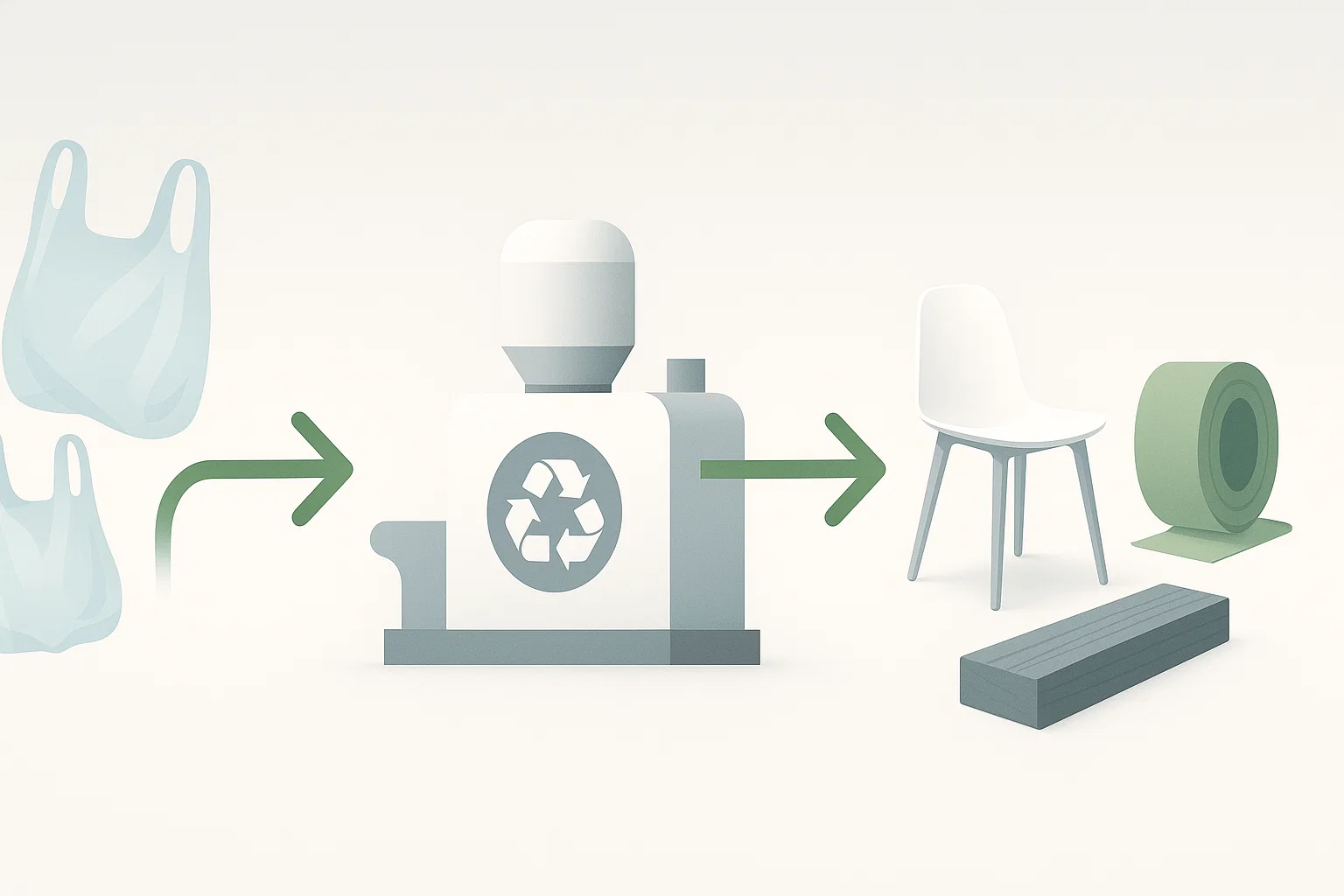

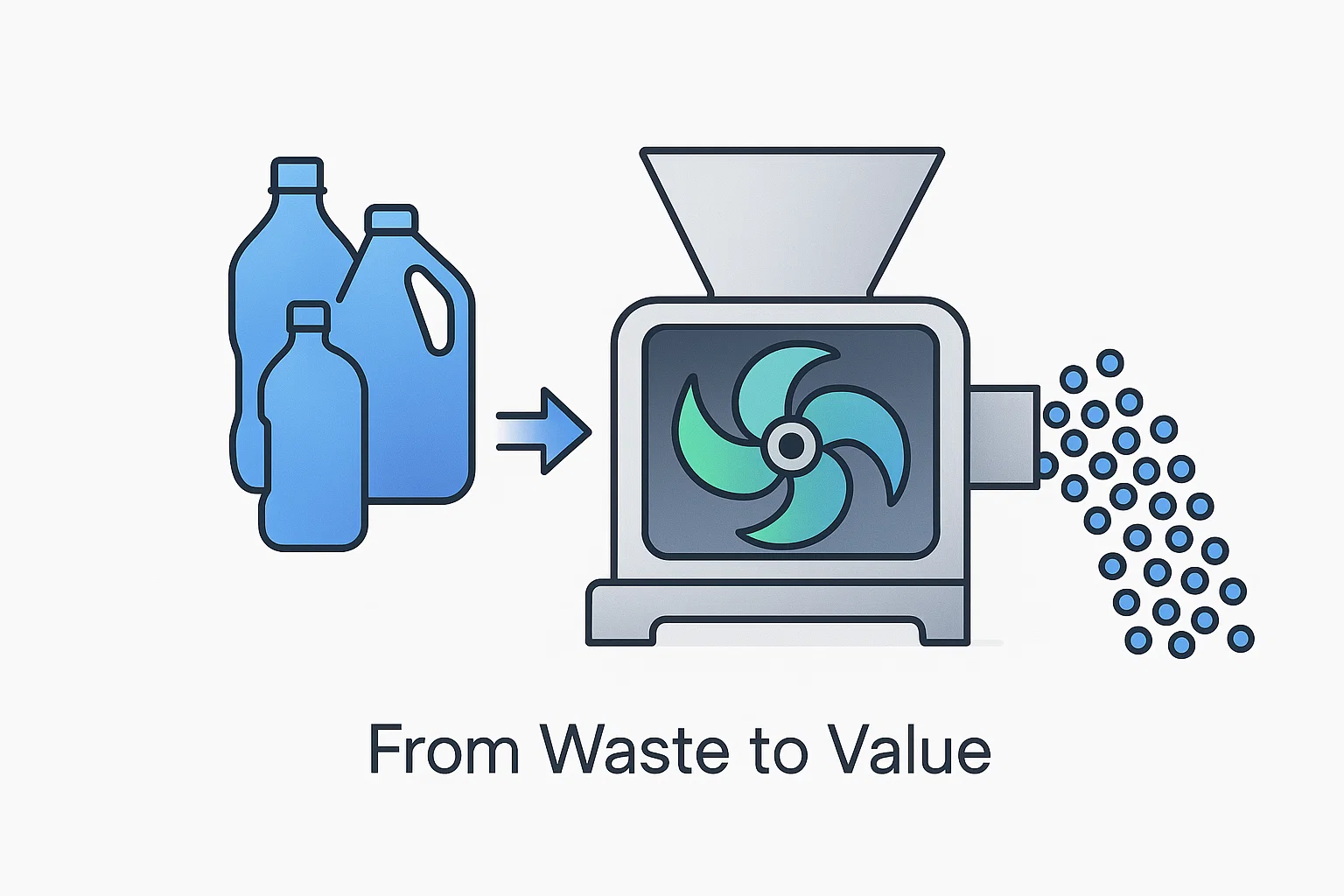

Plastic bottle recycling machines are sophisticated systems that process used plastic bottles into reusable materials. These machines typically perform several key functions: crushing, cleaning, de-labelling, and drying the plastic bottles to produce high-quality PET flakes or pellets. These recycled materials can then be used to manufacture new plastic products, supporting a circular economy and reducing environmental impact.

Energycle Machine’s recycling machines incorporate advanced technology to ensure precision and efficiency at every stage of the process. Their systems are designed to handle varying levels of contamination and different types of plastic bottles, providing customised solutions tailored to the needs of manufacturers and recycling professionals.

Key Features and Benefits

- High Efficiency and Automation: Energycle Machine’s plastic bottle recycling machines operate automatically with minimal manual intervention, enhancing productivity and reducing labour costs.

- Comprehensive Processing: From crushing to dewatering, the machines offer a complete recycling line that guarantees clean, industry-standard PET flakes suitable for direct reuse.

- Environmental Impact: By enabling effective recycling of plastic bottles, Energycle Machine supports waste reduction and resource conservation, aligning with global sustainability goals.

- Customisable Solutions: Recognising that different industries have unique requirements, Energycle Machine offers bespoke configurations to meet specific production volumes and quality standards.

Applications for Manufacturers and Industrial Buyers

Manufacturers looking to integrate recycled plastic into their production lines benefit from Energycle Machine’s reliable equipment that ensures consistent material quality. Industrial recycling equipment buyers can trust these machines to deliver robust performance, helping them meet increasing regulatory demands and consumer expectations for sustainable products.

The versatility of Energycle Machine’s recycling systems makes them suitable for various sectors, including packaging, automotive, textiles, and consumer goods, where recycled PET is increasingly valued.

Why Choose Energycle Machine?

With a strong reputation for technical expertise and innovation, Energycle Machine combines industry experience with state-of-the-art technology. Their commitment to quality and customer service ensures that clients receive not only top-tier machinery but also ongoing support and maintenance.

Integrating Energycle Machine’s recycling machines into your operations means investing in a future-proof solution that enhances your company’s environmental credentials and operational efficiency.

Frequently Asked Questions (FAQ)

Q1: What types of plastic bottles can Energycle Machine’s recycling machines process?

A1: The machines are designed primarily for PET bottles, including mineral water, soft drinks, and other beverage containers, accommodating various sizes and contamination levels.

Q2: How automated are the recycling machines?

A2: Energycle Machine’s systems feature high levels of automation, including crushing, washing, de-labelling, and drying processes, requiring minimal manual oversight.

Q3: Can the recycled PET flakes be used directly in manufacturing?

A3: Yes, the recycled PET flakes produced meet industry standards and can be directly used to manufacture new plastic products.

Q4: Does Energycle Machine provide customised recycling solutions?

A4: Absolutely. They tailor their recycling systems to match specific customer needs, production capacities, and quality requirements.

Take the Next Step with Energycle Machine

For manufacturers and industrial buyers committed to sustainable practices and operational excellence, Energycle Machine offers the perfect blend of innovation, reliability, and expertise in plastic bottle recycling machines. Discover how Energycle Machine can transform your recycling process by visiting their PET bottle recycling system page or contacting their team today to request a personalised quote.

In the current industrial landscape, optimizing your plastic recycling process not only supports environmental sustainability but also significantly enhances operational efficiency and profitability. At Energycle, we specialize in providing cutting-edge plastic recycling solutions, including state-of-the-art plastic recycling machines tailored for diverse industrial needs.

Here are ten practical, expert-approved tips to increase efficiency in your plastic recycling processes.

1. Proper Sorting at Source

Efficiency in plastic recycling begins at the source. Proper sorting drastically reduces contamination and improves the purity and quality of recycled materials. Implement clearly labeled sorting bins and educate your employees to ensure effective sorting from the start.

- Clearly labeled recycling bins

- Training for employees

- Regular audits and feedback

2. Invest in Advanced Plastic Recycling Machines

Upgrading to modern plastic recycling machines like those offered by Energycle can substantially improve your recycling process. These machines feature advanced technology that:

- Enhances sorting precision

- Increases processing speed

- Reduces energy consumption

By integrating these high-tech solutions, companies achieve higher recycling rates and lower operational costs.

3. Regular Maintenance of Equipment

Scheduled maintenance is vital for the longevity and efficiency of your plastic recycling machinery. Regular inspections and proactive maintenance help:

- Minimize downtime

- Prevent costly breakdowns

- Ensure continuous productivity

Energycle’s plastic recycling machines are designed for easy maintenance and durability, ensuring maximum uptime and efficiency.

4. Optimize Workflow and Process Design

An efficient workflow reduces unnecessary movements, minimizes delays, and streamlines your plastic recycling operation. Evaluate and redesign your recycling layout to:

- Minimize physical distances between processing stages

- Enhance material handling

- Optimize storage solutions

5. Train Your Workforce

Skilled and knowledgeable workers significantly impact the efficiency of the recycling process. Invest in ongoing training programs to help your workforce:

- Operate machinery proficiently

- Understand recycling standards and best practices

- Maintain safety and compliance

Energycle provides comprehensive training alongside our plastic recycling solutions, empowering your team to maximize efficiency.

6. Monitor and Measure Performance

Utilize key performance indicators (KPIs) to measure the efficiency of your recycling processes. Regular monitoring and data analysis enable you to:

- Identify bottlenecks and inefficiencies

- Make informed, data-driven decisions

- Continuously improve operational performance

7. Ensure Quality Control

Implementing rigorous quality control measures ensures the consistent quality of recycled plastics. Effective quality control practices include:

- Frequent inspections of raw and recycled materials

- Using advanced detection systems integrated into recycling machinery

- Immediate correction of identified issues

8. Foster Partnerships and Collaborations

Collaboration within the supply chain and industry partnerships can lead to shared best practices, innovation, and resource efficiency. Energycle actively engages with industry stakeholders to promote collaborative recycling solutions, enhancing efficiency and sustainability.

9. Leverage Automation and AI Technologies

Automation and artificial intelligence (AI) are revolutionizing the recycling industry. Modern plastic recycling machines equipped with AI can:

- Improve sorting accuracy

- Predict maintenance needs

- Enhance overall efficiency and productivity

Energycle offers innovative recycling machines embedded with AI and automation features, providing significant operational advantages.

10. Adopt Sustainable Practices

Incorporating sustainability into your recycling operations goes beyond efficiency—it positions your business as environmentally responsible, aligning with regulatory compliance and consumer expectations. Practices to adopt include:

- Reducing energy and water consumption

- Implementing circular economy principles

- Continuously innovating recycling methods

Energycle’s recycling solutions are designed with sustainability in mind, helping you meet your environmental objectives.

Frequently Asked Questions (FAQs)

Q1: How do modern plastic recycling machines from Energycle improve efficiency?

Energycle machines feature advanced sorting capabilities, automation, and reduced energy consumption, directly boosting efficiency and productivity.

Q2: What is the importance of sorting plastics before recycling?

Proper sorting reduces contamination, improves the quality of recycled plastics, and significantly enhances process efficiency.

Q3: How often should recycling machinery undergo maintenance?

Regular maintenance checks are recommended monthly, with comprehensive inspections quarterly or semi-annually, depending on usage intensity.

Q4: What training does Energycle provide with its recycling machines?

Energycle provides comprehensive operational, safety, and maintenance training programs tailored to each machine model.

Ready to Enhance Your Recycling Efficiency?

Boost your plastic recycling efficiency today by partnering with Energycle. Our expert team is ready to guide you towards optimal solutions tailored specifically to your operational needs.

Request a Quote or Contact Energycle today for a personalized consultation.

In the world of plastics recycling and manufacturing, selecting the appropriate equipment to ensure efficiency and purity is crucial. Rumtoo's Zig-Zag Air Classifier, also known as an air separator, is a powerful tool designed specifically to handle various types of plastics. In this guide, we’ll dive deep into the plastic materials that are best suited for processing with Rumtoo’s industry-leading Zig-Zag Air Classifier.

Understanding the Zig-Zag Air Classifier

Rumtoo’s Zig-Zag Air Classifier separates materials based on weight and aerodynamic properties using controlled airflow. Ideal for recycling facilities and manufacturers, this technology significantly improves the quality and purity of plastic materials, enhancing their market value and environmental sustainability.

For more detailed specifications, you can explore Rumtoo’s Zig-Zag Air Classifier.

Ideal Plastic Materials for Processing

Choosing the right materials is critical to maximizing the benefits of your air classifier. Here are the plastics that achieve optimal results:

1. PET (Polyethylene Terephthalate)

PET plastics, widely used in bottles, packaging, and textiles, greatly benefit from air classification due to their relatively uniform density and lightweight nature.

Benefits for PET:

- Improved purity and consistency

- Enhanced recycling efficiency

- Reduction of contaminants and foreign materials

2. HDPE (High-Density Polyethylene)

Commonly used in containers, piping, and automotive components, HDPE’s robust nature makes it highly compatible with air separators.

Benefits for HDPE:

- Increased efficiency in recycling processes

- Significant reduction in contamination

- Higher quality recycled outputs

3. LDPE (Low-Density Polyethylene)

Used primarily in packaging films and plastic bags, LDPE’s lightweight properties make it highly suitable for the Zig-Zag Air Classifier, ensuring excellent separation from contaminants.

Benefits for LDPE:

- Enhanced separation from heavier impurities

- Superior purity of recycled material

- Increased commercial value

4. PP (Polypropylene)

Polypropylene is prevalent in packaging, automotive parts, and textiles. Its moderate density and aerodynamic properties align perfectly with the air classifier technology.

Benefits for PP:

- Improved separation quality

- Higher recyclability and purity

- Increased market value post-processing

5. PS (Polystyrene)

Frequently found in consumer goods packaging, insulation, and electronics, polystyrene benefits significantly from precise air separation, ensuring minimal cross-contamination.

Benefits for PS:

- Efficient removal of contaminants

- High purity levels

- Enhanced market value for recycled PS

Materials Less Suited for Air Classification

Though versatile, air classifiers may face limitations with certain materials, particularly those with similar aerodynamic characteristics or densities, such as:

- Mixed plastic composites

- Heavily contaminated plastics with adhesives or coatings

- Plastics mixed with metal or glass fragments

In such cases, additional preprocessing steps might be necessary before classification.

How Rumtoo Enhances Your Recycling Process

Rumtoo’s Zig-Zag Air Classifier provides significant advantages, including:

- Precision Separation: Tailored airflow ensures optimal sorting accuracy.

- Energy Efficiency: Reduced energy consumption compared to traditional methods.

- Environmental Compliance: Helps businesses meet stringent recycling regulations.

Rumtoo’s expertise in air classification technology positions it as a trusted partner for manufacturers aiming to elevate the quality and efficiency of their recycling processes.

Best Practices for Maximizing Air Classifier Efficiency

To ensure optimal results when using Rumtoo's Zig-Zag Air Classifier, consider these best practices:

- Regularly maintain and inspect your equipment

- Ensure proper preprocessing of plastics (cleaning, shredding)

- Monitor and adjust airflow settings based on specific plastic types

- Train operators thoroughly on equipment handling and adjustments

FAQ Section

Q: What makes Rumtoo’s Zig-Zag Air Classifier unique?

A: Rumtoo’s technology offers superior aerodynamic separation, enhanced energy efficiency, and precision sorting, ideal for diverse plastic recycling needs.

Q: Can mixed plastics be processed effectively?

A: While the classifier excels at sorting specific plastics, mixed plastics may require additional preprocessing to optimize efficiency.

Q: Is the air classifier suitable for industrial-scale operations?

A: Absolutely. Rumtoo’s Zig-Zag Air Classifier is designed specifically for industrial applications, offering high throughput and reliability.

Q: What maintenance does the Zig-Zag Air Classifier require?

A: Regular inspections, cleaning, and routine checks of airflow settings will maintain peak performance.

Ready to Upgrade Your Recycling Operations?

Discover how Rumtoo’s Zig-Zag Air Classifier can transform your plastic recycling process. Contact Rumtoo today or request a quote to elevate your recycling capabilities, reduce contamination, and enhance your business sustainability.

In the rapidly evolving world of plastic recycling, efficient material handling equipment forms the backbone of successful operations. Among the critical components that ensure smooth workflow and optimal productivity, the screw discharge bin stands out as an indispensable piece of machinery. This comprehensive guide explores everything industrial recycling professionals need to know about screw discharge bins, from their fundamental operation to advanced selection criteria.

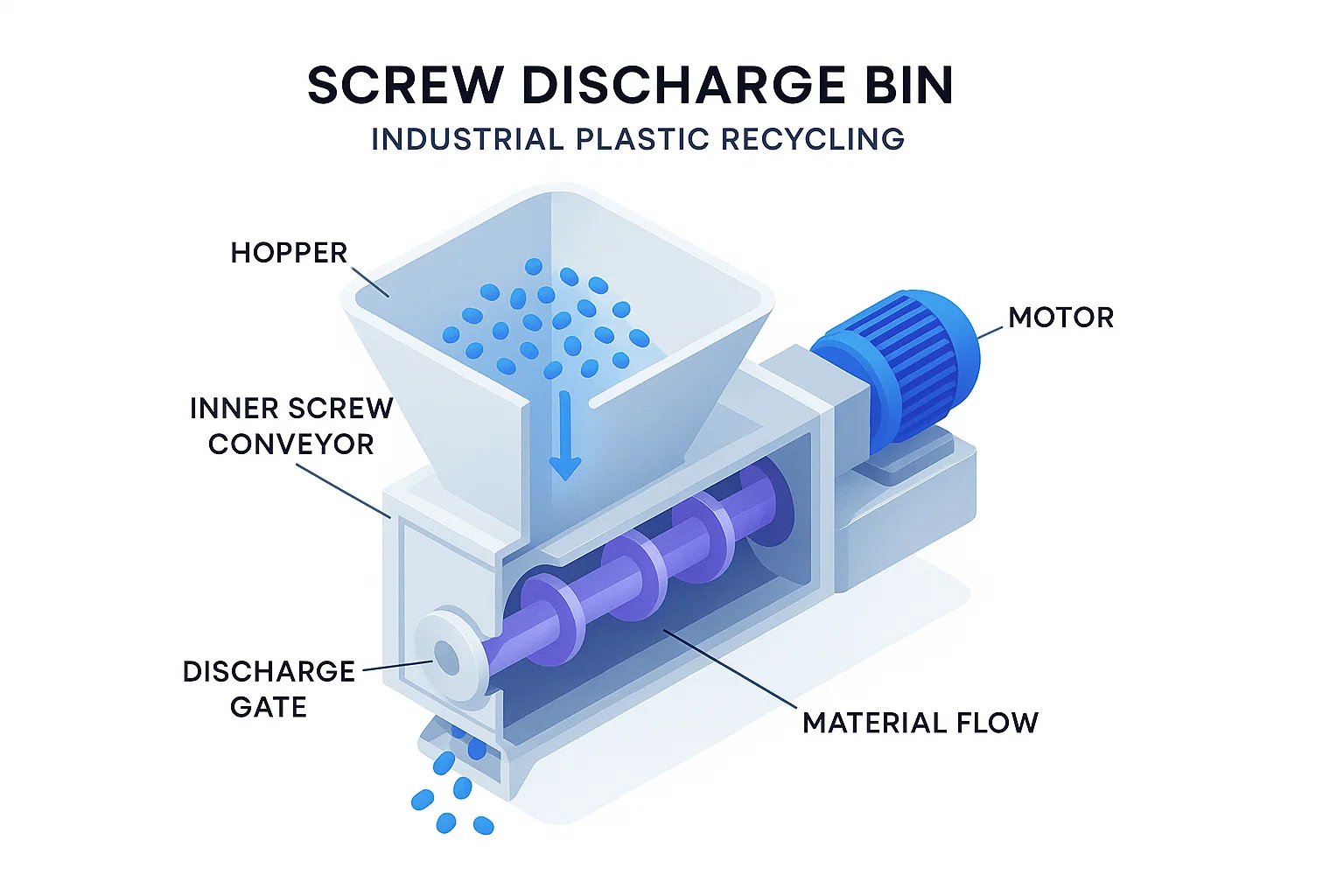

What is a Screw Discharge Bin?

A screw discharge bin is a specialised storage and material handling system designed to receive, store, and systematically discharge processed plastic materials in recycling facilities. Unlike conventional gravity-fed bins, these units incorporate an internal screw conveyor mechanism that provides controlled, continuous material flow whilst preventing bridging, rat-holing, and other common discharge problems associated with bulk plastic materials.

The fundamental design consists of a robust hopper or bin structure fitted with an internal auger or screw conveyor positioned at the discharge point. This configuration ensures consistent material flow rates and eliminates the irregular discharge patterns that can disrupt downstream processing equipment.

Key Components and Design Features

Primary Structural Elements

Bin Structure: Typically fabricated from heavy-duty steel or stainless steel, the bin features sloped walls optimised for material flow. The internal surfaces are often polished or coated to reduce friction and prevent material adhesion.

Screw Conveyor Assembly: The heart of the system comprises a helical screw mounted on a central shaft, designed with specific pitch and diameter ratios to handle various plastic material types effectively.

Drive System: A variable-speed motor and gearbox combination provides precise control over discharge rates, allowing operators to match output to downstream equipment requirements.

Discharge Gate: An adjustable gate mechanism at the bin's outlet enables fine-tuning of material flow characteristics and complete shut-off when required.

Advanced Features

Modern screw discharge bins incorporate sophisticated features such as level sensors, vibration systems for difficult materials, and automated control systems that integrate seamlessly with plant-wide process control networks.

How Screw Discharge Bins Work

The operational principle centres on the controlled rotation of the internal screw conveyor. As plastic materials enter the bin from above, they settle around the screw mechanism. When discharge is required, the screw rotates at predetermined speeds, creating a positive displacement action that moves material towards the discharge outlet.

This mechanical action overcomes the natural tendency of plastic flakes, pellets, or powders to form bridges or create uneven flow patterns. The continuous, gentle agitation provided by the screw ensures that materials maintain their flow properties throughout the storage period.

Material Flow Dynamics

The screw's helical design creates a first-in, first-out flow pattern, preventing material segregation and ensuring consistent quality in the discharged product. The controlled nature of the discharge eliminates the pulsing or surging common with gravity-fed systems, providing steady material flow to downstream equipment.

Applications in Plastic Recycling

Primary Processing Applications

Post-Washing Storage: Following washing operations, wet plastic flakes require controlled discharge to prevent compaction and ensure proper drainage. Screw discharge bins excel in this application by maintaining material movement without damaging delicate flakes.

Pellet Handling: After pelletising operations, hot plastic pellets need controlled cooling and discharge. The gentle action of screw discharge bins prevents pellet deformation whilst maintaining consistent feed rates to packaging or further processing equipment.

Secondary Processing Integration

Blending Operations: When multiple plastic streams require mixing, screw discharge bins can be configured in parallel to provide precise flow control for accurate blend ratios.

Quality Control Points: Strategic placement of screw discharge bins creates natural sampling points where quality control personnel can monitor material characteristics without disrupting production flow.

Types and Configurations

Standard Configurations

Single Screw Systems: The most common configuration, featuring one screw conveyor optimised for general-purpose plastic handling applications.

Twin Screw Arrangements: For high-capacity operations or difficult materials, twin screw systems provide increased throughput and improved material handling characteristics.

Specialised Designs

Heated Bins: For materials requiring temperature maintenance, heated screw discharge bins incorporate steam or electric heating systems to prevent material solidification.

Dust-Tight Models: When handling fine plastic powders or dusty materials, sealed designs with dust collection ports maintain clean working environments.

Sanitary Versions: For food-grade plastic recycling, special surface finishes and washdown capabilities ensure hygiene compliance.

Benefits for Industrial Operations

Operational Advantages

Consistent Flow Rates: Unlike gravity-fed systems that can experience variable discharge rates, screw discharge bins maintain steady output regardless of material level or characteristics.

Reduced Labour Requirements: Automated operation eliminates the need for manual intervention to clear blockages or restart material flow.

Improved Safety: Enclosed design and mechanical discharge systems reduce worker exposure to materials and eliminate the need for manual bin agitation.

Economic Benefits

Increased Throughput: Consistent material flow prevents downstream equipment starvation, maximising overall line efficiency and production capacity.

Reduced Maintenance: Elimination of bridging and material hang-up reduces wear on downstream equipment and decreases unplanned maintenance requirements.

Quality Consistency: Controlled discharge maintains material integrity and reduces contamination risks.

Selection Criteria and Specifications

Capacity Considerations

Proper sizing requires careful analysis of upstream production rates, downstream equipment requirements, and desired storage capacity. Industry best practice suggests sizing bins to provide 15-30 minutes of storage at maximum production rates.

Material Compatibility

Different plastic materials exhibit varying flow characteristics. PET flakes behave differently from HDPE pellets, requiring specific screw designs and operating parameters. Key considerations include:

- Material bulk density

- Particle size distribution

- Moisture content

- Temperature requirements

- Abrasiveness characteristics

Integration Requirements

Modern recycling facilities operate as integrated systems where equipment interfaces are critical. Essential integration factors include:

- Control system compatibility

- Physical space constraints

- Maintenance access requirements

- Safety system integration

Installation and Maintenance

Installation Best Practices

Proper installation begins with adequate foundation design to support fully loaded bin weights and dynamic loads from the screw mechanism. Structural connections must accommodate thermal expansion and vibration whilst maintaining precise alignment of drive components.

Electrical installation requires attention to motor protection, variable frequency drive compatibility, and integration with plant control systems. Safety systems including emergency stops, access interlocks, and level alarms must be properly configured and tested.

Preventive Maintenance Programmes

Successful operation depends on regular maintenance schedules addressing key wear points and system components.

Daily Inspections: Visual checks of discharge rates, unusual noises, or vibrations that might indicate developing problems.

Weekly Maintenance: Lubrication of bearing points, inspection of drive belt tension, and verification of control system operation.

Monthly Services: Detailed inspection of screw wear, shaft alignment checks, and calibration of level sensors and flow controls.

Annual Overhauls: Complete drive system inspection, bearing replacement as required, and comprehensive safety system testing.

Troubleshooting Common Issues

Flow Rate Problems

Inconsistent discharge rates often indicate wear in the screw flights or changes in material characteristics. Systematic troubleshooting involves checking screw wear patterns, verifying drive system operation, and analysing material properties.

Material Bridging

Despite mechanical agitation, some materials may still bridge under specific conditions. Solutions include adjusting screw speed, modifying discharge gate settings, or installing supplementary flow aids.

Drive System Issues

Motor overload conditions typically result from material compaction, foreign object contamination, or mechanical binding. Proper diagnosis requires systematic checking of electrical systems, mechanical components, and material conditions.

Future Developments and Innovations

The plastic recycling industry continues evolving, driving innovations in material handling equipment. Emerging trends include smart sensors for predictive maintenance, advanced materials for improved wear resistance, and integrated systems that optimise energy consumption whilst maximising throughput.

Artificial intelligence and machine learning applications are beginning to appear in process control systems, enabling predictive adjustments based on material characteristics and production requirements.

Conclusion

Screw discharge bins represent a critical investment in modern plastic recycling operations, providing the controlled material handling necessary for efficient, consistent production. Their ability to handle diverse plastic materials whilst maintaining steady flow rates makes them indispensable for facilities seeking to maximise throughput and product quality.

For industrial recycling equipment buyers, understanding the capabilities and requirements of screw discharge bins ensures informed decisions that support long-term operational success. As the recycling industry continues advancing towards greater efficiency and automation, these robust, reliable systems will remain fundamental to successful operations.

When evaluating screw discharge bins for your facility, consider not just immediate requirements but also future expansion plans and evolving material handling needs. Proper selection and installation of these systems provides the foundation for years of reliable, efficient operation in your plastic recycling facility.