În industria reciclării plasticului, alegerea utilajelor potrivite este esențială pentru optimizarea eficienței, a calității produsului și a succesului operațional. Două echipamente frecvent discutate sunt peletizatoare şi granulatoare, dar ce anume le diferențiază? La Energycle, ne specializăm în furnizarea de produse de ultimă generație utilaje de reciclare a plasticului, inclusiv ambele peletizatoare de plastic şi granulatoare de plastic, adaptate pentru a satisface nevoile profesioniștilor din domeniul reciclării industriale, inginerilor și cumpărătorilor de echipamente. Acest articol explorează principalele diferențe dintre peletizatoare și granulatoare, aplicațiile acestora și cum să alegeți echipamentul potrivit pentru operațiunile dumneavoastră de reciclare.

Înțelegerea peletizatoarelor și granulatoarelor: o prezentare generală

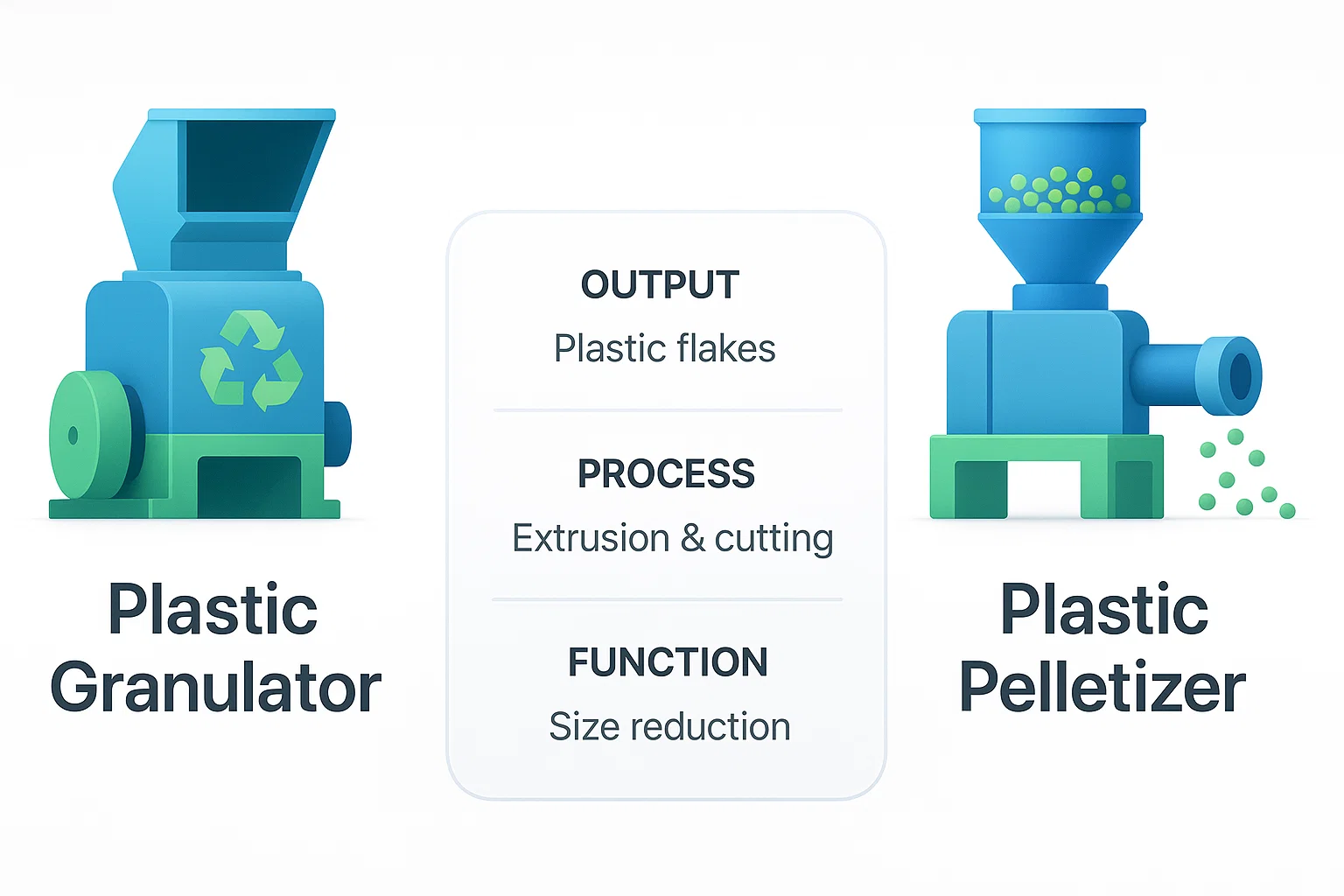

Atât peletizatoarele, cât și granulatoarele joacă roluri esențiale în procesarea deșeurilor de plastic, dar servesc scopuri distincte în fluxul de lucru pentru reciclare. granulator reduce materialele plastice în bucăți mai mici, ușor de manevrat, în timp ce peletizator transformă aceste piese în pelete uniforme, potrivite pentru fabricarea ulterioară. Să analizăm funcțiile, designul și aplicațiile lor pentru a oferi claritate profesioniștilor din industrie.

Ce este un granulator de plastic?

O granulator de plastic este o mașină concepută pentru a măcina sau măcina deșeurile de plastic în fulgi sau granule mici, neregulate, de obicei cu dimensiuni cuprinse între 2 și 12 mm. Aceste granule sunt adesea primul pas în procesul de reciclare, pregătind materialele pentru procesare ulterioară, cum ar fi extrudarea sau peletizarea.

- FuncţieGranulatoarele folosesc lame sau rotoare ascuțite pentru a tăia deșeurile de plastic (de exemplu, sticle, folii sau resturi industriale) în bucăți mai mici.

- IeșireGranule sau fulgi de formă neregulată, ideale ca materie primă pentru procesele ulterioare.

- AplicațiiFolosit în reducerea dimensiunii inițiale pentru o gamă largă de materiale plastice, inclusiv PET, HDPE, PP și PVC.

- Caracteristici cheie:

- Sisteme de tăiere de mare viteză pentru descompunerea eficientă a materialului.

- Design robust pentru a face față materialelor plastice dificile și contaminanților.

- Dimensiuni personalizabile ale sitei pentru a controla producția de granule.

Pentru o analiză mai detaliată a granulatoarelor noastre de înaltă performanță, vizitați Pagina Granulatoarelor de plastic.

Ce este un peletizator de plastic?

O peletizator de plastic, pe de altă parte, preia material plastic procesat (adesea granule dintr-un granulator) și îl transformă în pelete cilindrice uniforme. Aceste pelete sunt foarte căutate în industria prelucrătoare datorită dimensiunii, formei și densității lor constante, ceea ce asigură o alimentare lină în extrudere sau mașini de turnare prin injecție.

- FuncţiePeletizatoarele topesc și extrudează granule de plastic, modelându-le în pelete uniforme printr-o matriță.

- IeșirePelete cilindrice, consistente (de obicei 2-5 mm în diametru).

- AplicațiiFolosit în etapele finale ale reciclării pentru a produce pelete de înaltă calitate pentru fabricarea de noi produse din plastic.

- Caracteristici cheie:

- Control precis al temperaturii pentru o calitate constantă a peleților.

- Sisteme avansate de matrițe pentru forme uniforme ale peletelor.

- Opțiuni pentru sisteme de peletizare răcite cu apă sau cu aer.

Explorați gama noastră de soluții de peletizare de ultimă generație pe site-ul nostru Pagina de peletizare din plastic.

Diferențe cheie între peletizatoare și granulatoare

Pentru a vă ajuta să luați decizii informate pentru operațiunile dumneavoastră de reciclare, haideți să comparăm peletizatoarele și granulatoarele în funcție de mai mulți factori critici:

| Aspect | Granulator de plastic | Peletizator de plastic |

|---|---|---|

| Scop | Reducerea dimensiunii deșeurilor de plastic în granule/fulgi | Modelarea granulelor în pelete uniforme |

| Material de intrare | Deșeuri de plastic (de exemplu, sticle, folii, resturi) | Granule preprocesate sau plastic topit |

| Ieșire | Granule sau fulgi neregulați (2–12 mm) | Pelete cilindrice uniforme (2–5 mm) |

| Proces | Tăiere sau șlefuire mecanică | Topire, extrudare și tăiere |

| Aplicații | Etapa inițială de reciclare | Etapa finală pentru fabricarea materiilor prime |

| Complexitatea echipamentelor | Design mai simplu, concentrat pe tăiere | Mai complex, implicând încălzire și extrudare |

Diagramă: Flux de lucru pentru reciclarea plasticului

Pentru a ilustra rolurile granulatoarelor și peletizatoarelor, următoarea diagramă prezintă un proces tipic de reciclare a plasticului:

[Deșeuri de plastic] → [Granulator: Reducerea dimensiunii] → [Granule] → [Peletizator: Topire și modelare] → [Pelete uniforme] → [Fabricație]Acest flux de lucru evidențiază modul în care granulatoarele și peletizatoarele lucrează în tandem pentru a transforma deșeurile de plastic brute în materii prime de înaltă calitate pentru produse noi.

Alegerea echipamentului potrivit nevoilor dumneavoastră

Selectarea între o granulator de plastic și o peletizator depinde de obiectivele operaționale, tipurile de materiale și cerințele de producție. Iată câteva aspecte cheie:

- Tipul și volumul materialului:

- Granulatoare sunt ideale pentru procesarea diverselor tipuri de deșeuri de plastic, inclusiv materiale rigide și flexibile. Dacă unitatea dumneavoastră gestionează volume mari de materiale plastice mixte, un granulator este esențial pentru reducerea inițială a dimensiunii.

- Peletizatoare sunt potrivite pentru operațiuni axate pe producerea de pelete uniforme de înaltă calitate pentru aplicații specifice de fabricație.

- Cerințe privind produsul finit:

- Dacă clienții dumneavoastră solicită peleți de înaltă calitate și consistență pentru extrudare sau turnare, un peletizator este esențial pentru a îndeplini aceste standarde.

- Granulele dintr-un granulator pot fi suficiente pentru aplicații mai puțin stringente sau ca etapă intermediară.

- Integrare cu sistemele existente:

- Multe instalații de reciclare folosesc ambele mașini în secvență. De exemplu, al nostru granulatoare de plastic pregătim eficient materialele pentru noi peletizatoare de plastic, asigurând un proces de reciclare fără probleme.

- Buget și spațiu:

- Granulatoarele sunt în general mai puțin complexe și mai rentabile, ceea ce le face un bun punct de plecare pentru operațiuni mai mici.

- Peletizatoarele, cu sistemele lor avansate de extrudare, pot necesita o investiție mai mare, dar oferă un randament superior producătorilor la scară largă.

De ce să alegeți utilajele de reciclare a plasticului de la Energycle?

La Energycle, înțelegem nevoile unice ale profesioniștilor și inginerilor din domeniul reciclării industriale. granulatoare de plastic şi peletizatoare de plastic sunt proiectate cu tehnologie de ultimă generație pentru a maximiza eficiența, durabilitatea și calitatea rezultatelor. Iată de ce echipamentele noastre ies în evidență:

- Inginerie de precizieMașinile noastre sunt construite pentru a manipula o gamă largă de materiale plastice cu timpi de nefuncționare minimi.

- Soluții personalizateOferim configurații personalizate pentru a se potrivi nevoilor dumneavoastră specifice de reciclare.

- Focus pe sustenabilitateEchipamentele noastre susțin principiile economiei circulare, ajutându-vă să reduceți deșeurile și să creați produse reciclate de înaltă valoare.

- Suport de specialitateEchipa noastră oferă îndrumare completă, de la selecția echipamentelor până la instalare și întreținere.

Concluzie

Pe scurt, diferența dintre un granulator de plastic și o peletizator constă în funcția, producția și rolul lor în procesul de reciclare. Granulatoarele sunt esențiale pentru descompunerea deșeurilor de plastic în granule ușor de gestionat, în timp ce peletizatoarele transformă aceste granule în pelete uniforme, gata de fabricație. Înțelegând aceste distincții, puteți lua decizii informate pentru a vă optimiza operațiunile de reciclare.

La Energycle, ne angajăm să vă oferim afacerea cu utilaje de reciclare de top. Indiferent dacă aveți nevoie de un echipament robust granulator de plastic sau de înaltă precizie peletizator de plastic, soluțiile noastre sunt concepute pentru a oferi rezultate excepționale. Contactați-ne astăzi pentru a discuta despre cerințele dumneavoastră și pentru a descoperi cum vă putem sprijini obiectivele de reciclare.