The Ultimate Waste Tyre Cutting Machine

Effortlessly transform scrap tyres into valuable, manageable rubber blocks with unparalleled efficiency and precision.

Request a QuoteUnmatched Durability

Equipped with wear-resistant blades made from high-quality imported materials for a long service life.

High-Efficiency Operation

The integrated rolling shelf and rotary platform streamline tyre handling, maximising your throughput.

Advanced Hydraulic System

Features a low-noise, high-pressure pump for stable, reliable performance and enhanced machine longevity.

Intelligent & Safe Design

Incorporates automatic repositioning after each cut and an anti-sticking mechanism for smooth, uninterrupted operation.

A Simple & Efficient Workflow

Load Tyre

Place a debeaded tyre onto the rotary platform.

Initiate Cut

The machine automatically secures and cuts the tyre into blocks.

Auto-Reposition

After a cut, the system repositions for the next cycle.

Collect Blocks

Uniform rubber blocks are ready for further processing or sale.

Key Components & Functionality

- Premium Cutting Blades: Fabricated from specially imported, hardened alloy to ensure superior wear resistance and precise cuts every time.

- Rotary Platform & Rolling Shelf: Ergonomically designed to simplify loading and handling, reducing manual effort and speeding up the process.

- Advanced Hydraulic Station: Utilises internationally recognised constant power variable plunger pump technology, ensuring stable high pressure with minimal noise.

- Robust Body Frame: Engineered for maximum stability and durability, capable of withstanding continuous heavy-duty operation.

Technical Specifications

| Parameter | Model 900 | Model 1200 |

|---|---|---|

| Capacity (Pcs/H) | 10–30 | 20–40 |

| Handling Tyre Diameter (mm) | ≤Φ1000 | ≤Φ1200 |

| Motor Power (kW) | 5.5 | 7.5 |

| Working Pressure (MPa) | 8 | 12 |

| Weight (Tonne) | 1.8 | 2.5 |

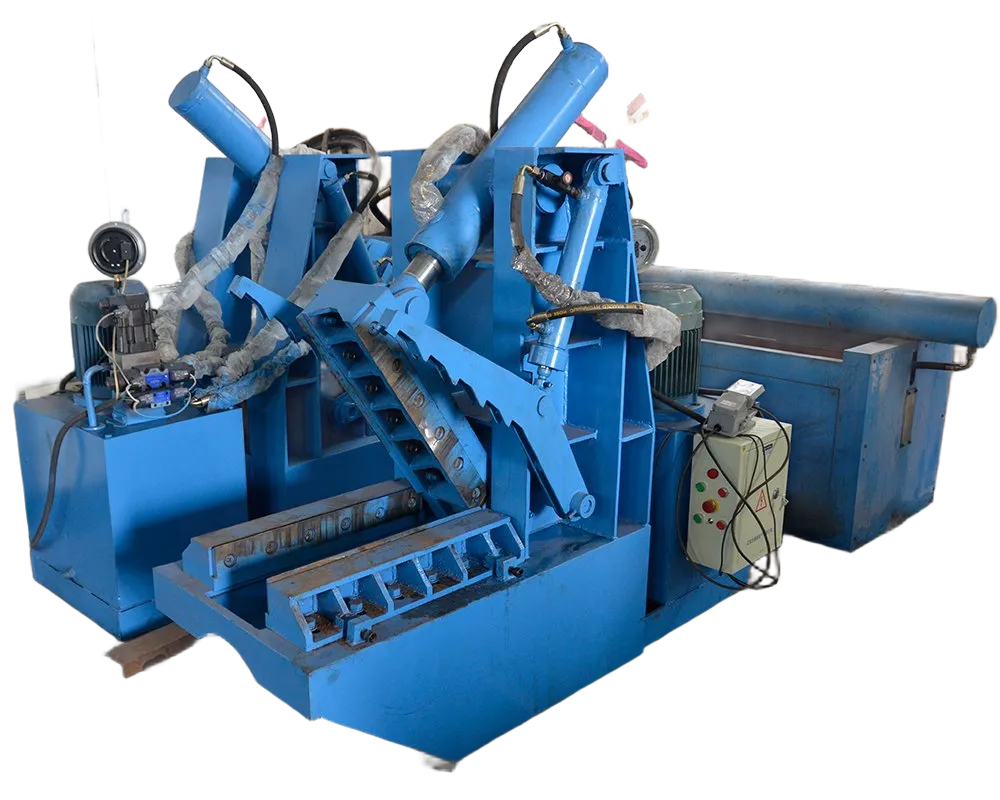

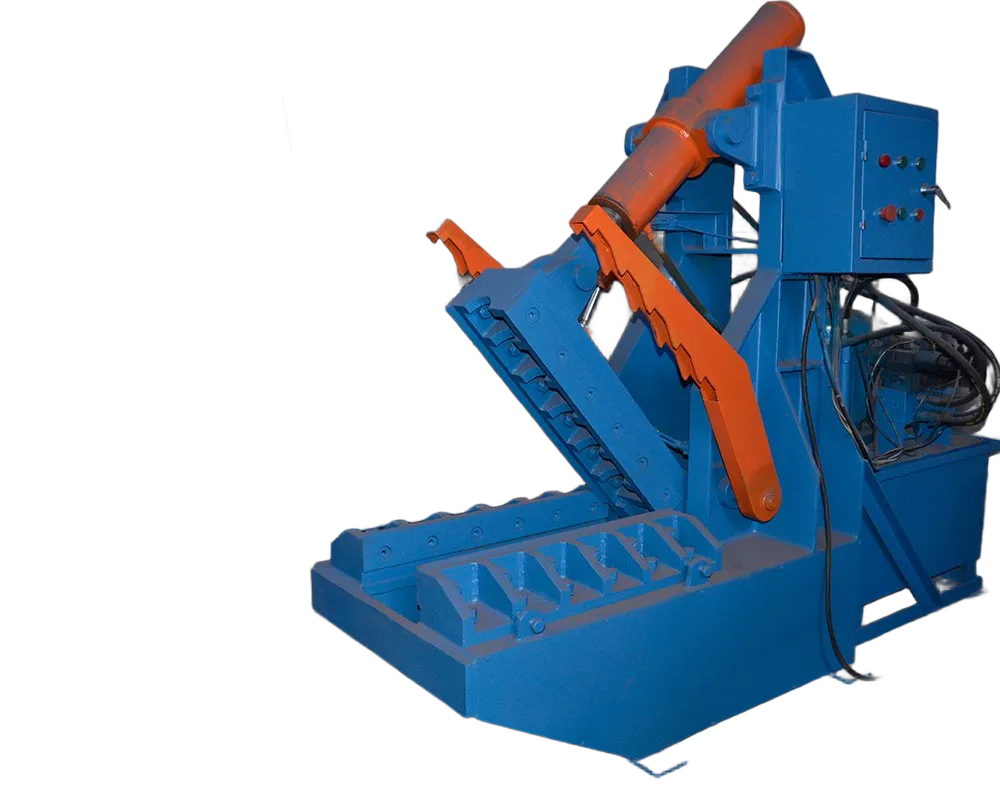

Machine Showcase

Get Your Customised Solution & Quote

Our experts are ready to help you choose the right model and configuration for your specific needs. Fill out the form below to receive a no-obligation proposal and pricing information.

Frequently Asked Questions

What types of tyres can this machine process?

The machine is designed to cut a wide variety of car, truck, and OTR tyres, including steel-belted and fibre tyres. For optimal performance, tyres must be debeaded (have the steel bead wire removed) before cutting.

Is a specialist operator required to run the machine?

No. The machine is designed for ease of use with a straightforward control cabinet. Basic training is sufficient for an operator to manage the machine safely and efficiently.

What is the typical maintenance schedule?

Routine maintenance includes daily checks of the hydraulic system, regular lubrication of moving parts, and periodic inspection of the blade for sharpness. A detailed maintenance schedule is provided in the user manual.