Shredders play a pivotal role in the recycling industry, especially when it comes to processing film and fiber waste. These machines not only enhance the effici...

Revolutionary Plastic Recycling Solutions: A Guide to Innovative Equipment

The need for effective plastic recycling solutions has never been more urgent. With the increasing amount of plastic waste being generated worldwide, it is cruc...

6 Ways to Extend the Lifespan of Your Single Shaft Shredder

Ensuring the longevity of your Single Shaft Shredder is crucial for maximizing its performance and efficiency in waste management and recycling operations. This...

What Are the Key Components of a Single Shaft Shredder?

Understanding the intricacies of a Single Shaft Shredder can be crucial for those operating in recycling or waste management industries. This type of shredder p...

How to Troubleshoot Common Issues with a Single Shaft Shredder?

Dealing with operational issues in heavy machinery can be daunting. A Single Shaft Shredder is no exception. This versatile equipment, crucial for effective was...

How to Properly Maintain a Single Shaft Shredder?

Proper maintenance is crucial for the longevity and efficiency of industrial machinery. A Single Shaft Shredder is no exception. This versatile equipment, essen...

Understanding PVC Pipe Horizontal Crushers: Key Features and Benefits for Your Business

In the bustling world of industrial manufacturing and recycling, efficiency isn’t just a goal—it’s a necessity. PVC pipe horizontal crushers are at the fo...

How PVC Pipe Horizontal Crushers Revolutionize Waste Management in the Plastic Industry

In the world of plastic manufacturing, waste management is no small affair, and the introduction of PVC pipe horizontal crushers has been nothing short of a gam...

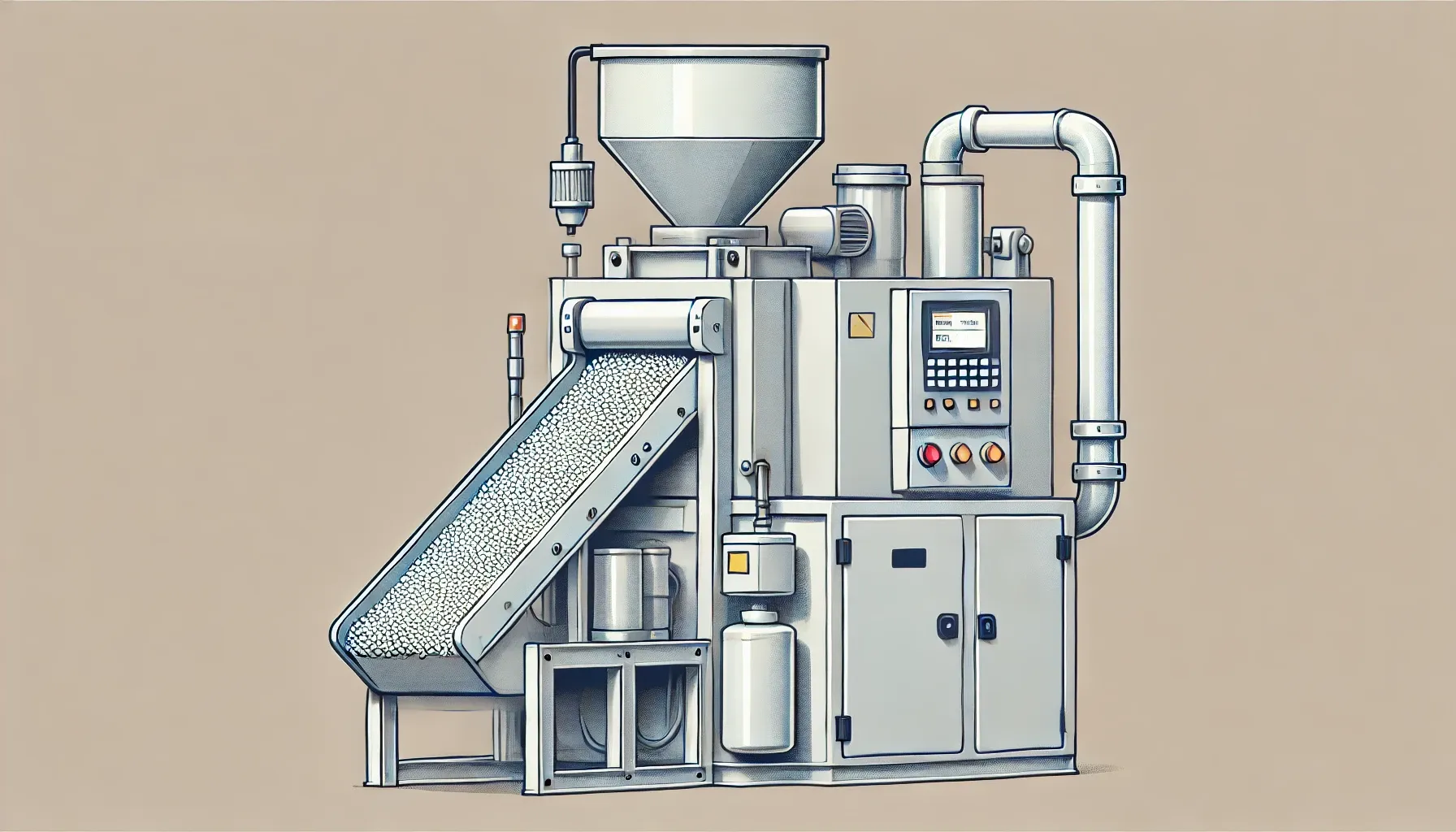

Budget vs. High-End Plastic Pelletizer Machines

When it comes to purchasing a plastic pelletizer machine, potential buyers are often faced with a variety of choices, ranging from budget-friendly models to hig...

Exploring the Factors Influencing the Cost of Plastic Pelletizer Machines

Plastic pelletizer machines are crucial in the plastics industry, turning raw plastic materials into pellets that can be used for manufacturing various products...