Turn Wastewater Compliance into a Competitive Advantage

Our advanced DAF systems are engineered to tackle the toughest challenges in TSS, O&G, and BOD₅ removal — helping you slash operational costs and enhance your environmental stewardship.

Get a Custom QuoteEngineered for Performance and Reliability

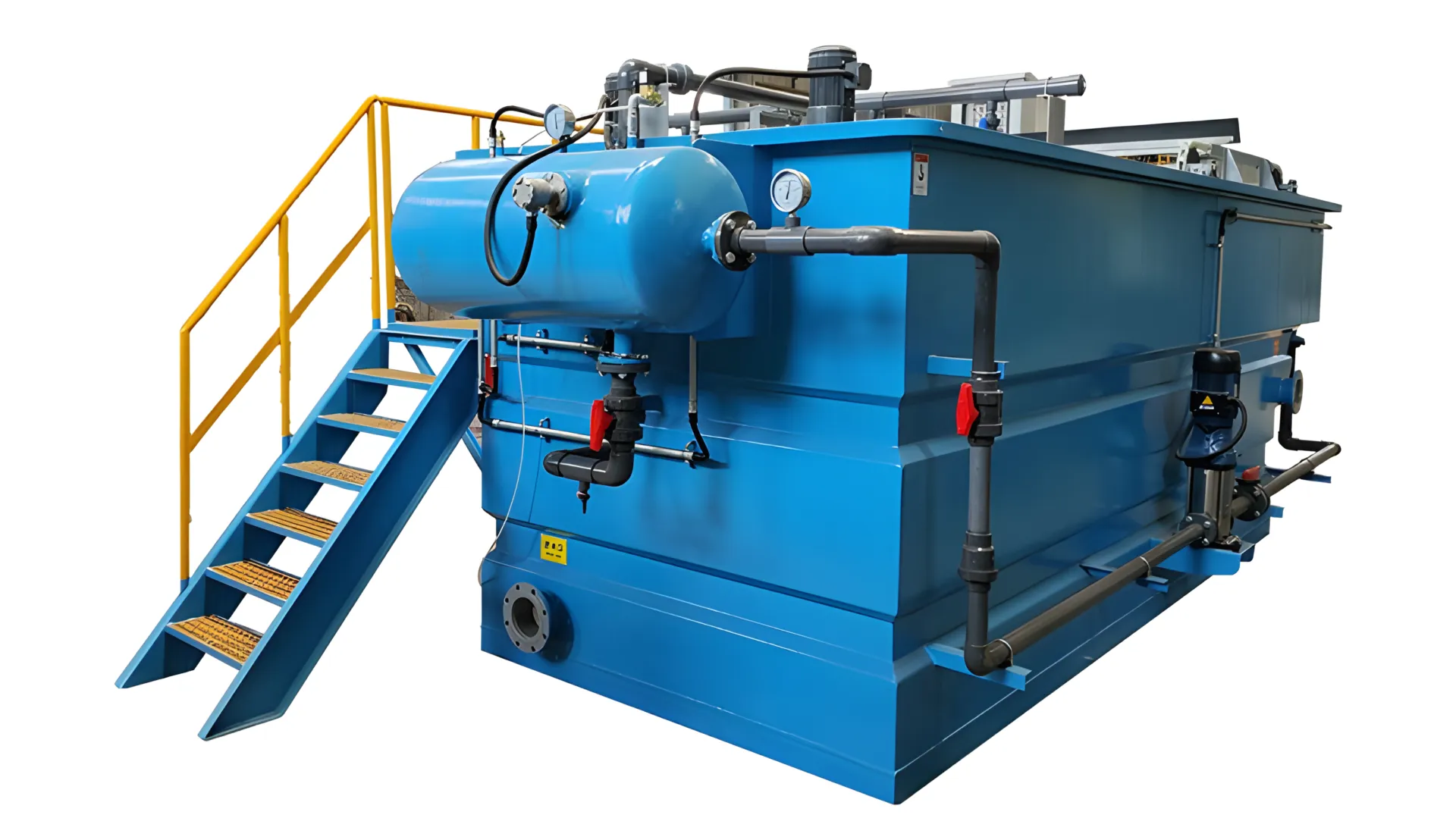

Explore the robust construction and thoughtful design of our DAF system. Every component is selected for maximum efficiency and a long service life.

-2.webp)

Key Construction Features

Our systems are built with high-grade stainless steel (SS304/316L) for superior corrosion resistance. The integrated lamella plates increase the effective surface area, resulting in a more compact and efficient unit.

-2.webp)

-3.webp?fit=crop&ar=1:1&auto=format,compress&fm=webp)

-4.webp?fit=crop&ar=1:1&auto=format,compress&fm=webp)

-5.webp?fit=crop&ar=1:1&auto=format,compress&fm=webp)

How It Works: A Four-Step Process

Our DAF system uses precisely controlled micro-bubble technology to efficiently separate contaminants, ensuring a clear, compliant effluent.

1. Pressurized Dissolution

A recycle stream of clarified water is pressurized and saturated with air, creating a dissolved air solution.

2. Micro-Bubble Release

This solution is introduced into the flotation tank, where the pressure drop causes millions of microscopic bubbles (20-50µm) to form.

3. Contaminant Flotation

The micro-bubbles adhere to suspended solids and flocs in the wastewater, lifting them to the surface as a float layer (sludge blanket).

4. Sludge Skimming

A mechanical skimmer removes the float layer for dewatering, while clarified water is discharged from the bottom of the unit.

Core Advantages

Our DAF system is more than just equipment; it's a strategic asset for cost reduction, operational efficiency, and sustainable growth.

Superior Removal Efficiency

Achieve up to 99% removal of TSS and FOG, drastically reducing the load on downstream treatment processes.

Significant Cost Savings

Our optimized design consumes up to 30% less energy and requires fewer chemical additives than conventional systems.

Compact Footprint

The integrated, vertical design saves valuable floor space, requiring only a fraction of the area of traditional clarifiers.

Facing These Wastewater Challenges?

High surcharges, compliance risks, and operational headaches can erode your profits. See how our DAF system provides the definitive solution.

Your Pain Points

- Inconsistent effluent quality and compliance failures.

- Large footprint of existing systems limits expansion.

- High energy and chemical consumption drive up costs.

- Complex operations require dedicated, skilled labor.

- High-volume, wet sludge leads to expensive disposal fees.

Our DAF Solution

- Reliable performance for consistent peace of mind.

- Compact design frees up valuable plant real estate.

- Energy-efficient operation that boosts your bottom line.

- Fully automated controls for simple, unattended operation.

- Drier sludge float reduces disposal volume and costs.

What Our Clients Say

Don't just take our word for it. See how we've helped businesses like yours succeed.

“The [Your Company Name] DAF system has been a game-changer. Our TSS levels are consistently below permit limits, so we no longer worry about EPA audits. It’s incredibly reliable and low-maintenance.”

“The ROI was clear within the first year. The system’s automation reduced our labor needs, and the drier sludge cut our disposal costs by nearly 40%. It was a smart investment for our bottom line.”

See It In Action

Watch our DAF system's superior performance in a real-world industrial setting.

Ideal for Industries Including: Food & Beverage Processing, Oil & Gas, Pulp & Paper, Dairy, Meat & Poultry, Industrial Laundries, and Municipal Water Treatment.

Technical Specifications

We offer a range of models to meet your specific flow rate requirements. Custom configurations are available upon request.

| Model | Flow Rate (GPM) | Dimensions L x W x H (ft) | Motor Power (HP) | Dry Weight (lbs) |

|---|---|---|---|---|

| DAF-22G | 22 | 13.1 x 7.9 x 7.2 | 3 | 3,970 |

| DAF-44G | 44 | 15.1 x 8.9 x 7.9 | 4 | 5,510 |

| DAF-88G | 88 | 18.0 x 9.8 x 8.2 | 5.5 | 8,380 |

| DAF-220G | 220 | 23.0 x 11.5 x 9.2 | 10 | 13,670 |

Frequently Asked Questions

Have questions? We have answers.

How long does installation and commissioning take?

What are the influent requirements for the system?

What kind of after-sales support do you offer?

Ready to Transform Your Wastewater Treatment?

Complete the form below. Our senior engineers will contact you within one business day to provide a no-obligation consultation, a preliminary system design, and a detailed quote.