EPS Foam Melting Machine

Transform bulky EPS foam into dense, valuable ingots with our advanced melting technology. Simplify storage, transport, and turn waste into a reusable resource.

Key Advantages

Efficiently minimize waste volume and create new revenue streams with our densification process.

Exceptional Densification

Achieves an outstanding volume reduction ratio of up to 90:1, drastically saving storage space (up to 90%) and transport costs.

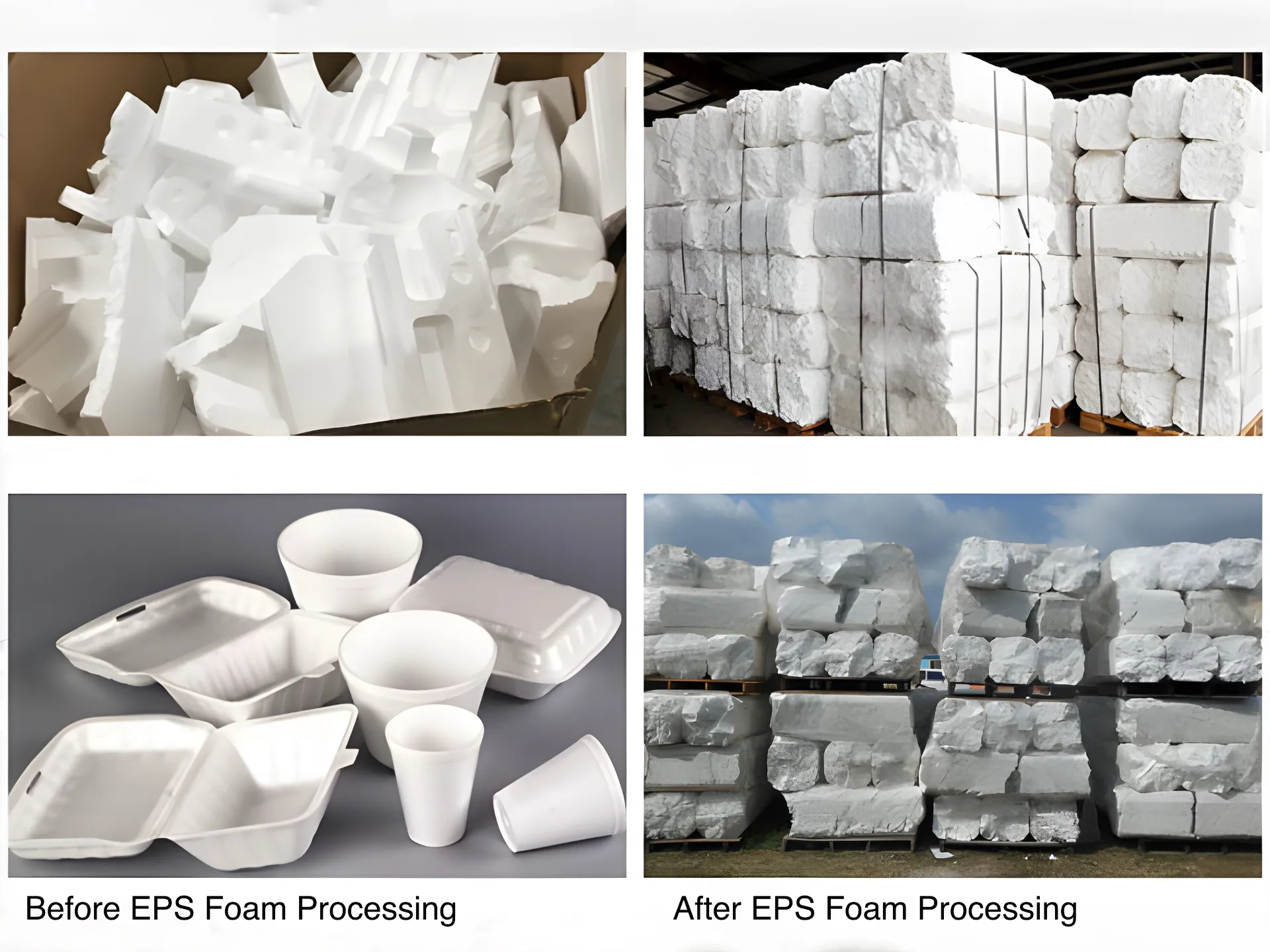

Creates Valuable Resources

Transforms waste foam into dense ingots or blocks, a highly sought-after commodity for various plastic recycling industries.

Energy Efficient Operation

Designed for optimal power usage with an automatic temperature control system that ensures efficient melting without energy waste.

Compact Footprint

Features a compact mechanical design, making it suitable for facilities with limited floor space while maintaining stable throughput.

Environmental Protection

Effectively reduces white pollution, minimizes landfill waste, and promotes a circular economy by enabling foam reuse.

Precise Temperature Control

Maintains ideal melting conditions to prevent burning or degradation, preserving the material quality for high-value recycling.

Working Principle

From loose waste to dense blocks in four simple, automated steps.

Feeding & Crushing

Waste foam is fed into the hopper, where a dual-shaft crushing system breaks it into smaller, manageable pieces.

Heating & Melting

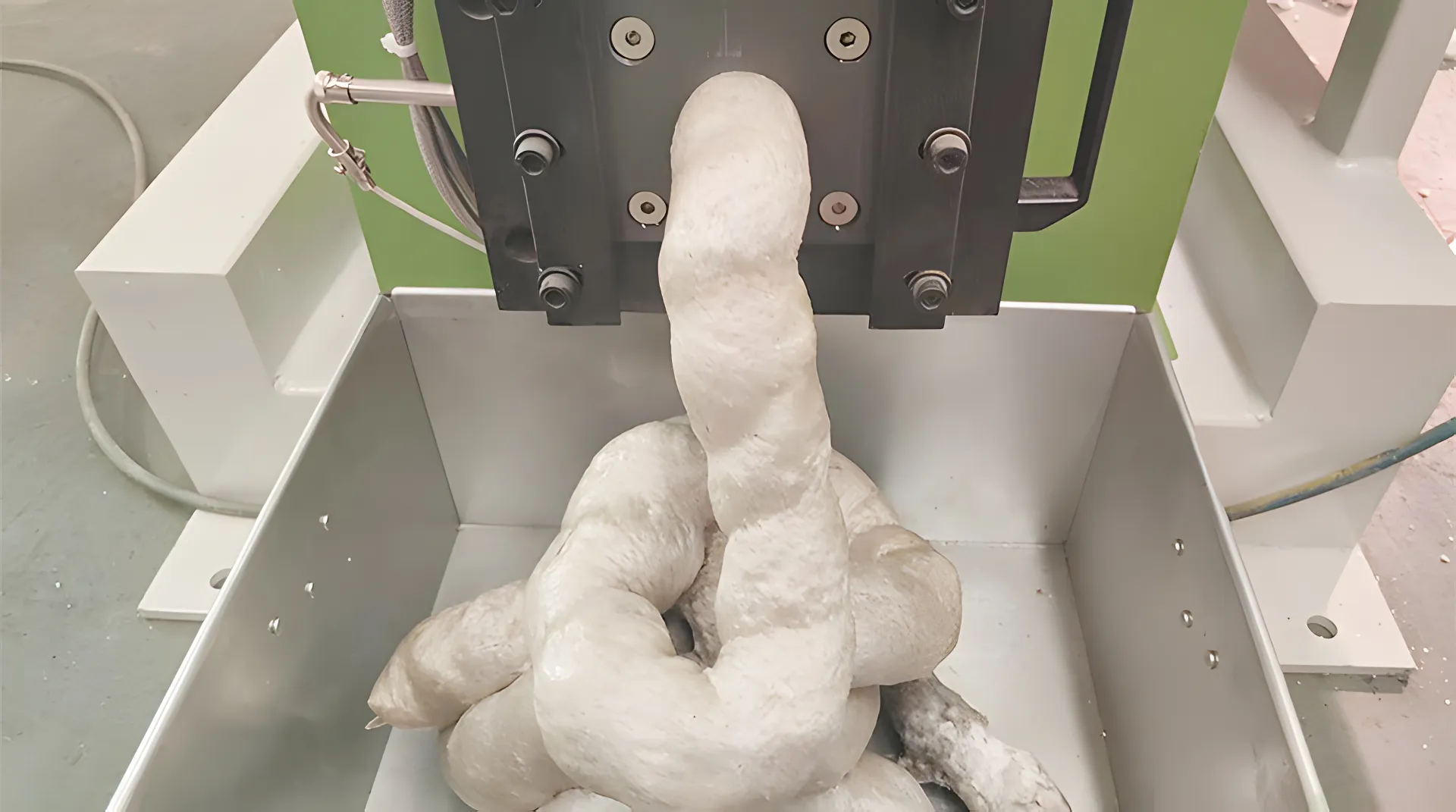

Crushed foam enters the barrel where a rotating screw conveys it through a precise heating zone to melt it.

Extrusion

The molten foam is continuously extruded through a die head, forming dense, solid ingots or blocks.

Discharge & Collection

Densified blocks are cooled and discharged, compact enough to stack on pallets for easy shipping.

Product Gallery

Technical Specifications

| Parameter | GL-HM100 | GL-HM200 | GL-HM400 |

|---|---|---|---|

| Screw Diameter | Φ100 mm | Φ180–120 mm | Φ180–120 mm |

| Screw Length | 1050 mm | 2500 mm | 2500 mm |

| Screw Speed | 150 r/min | 110 r/min | 110 r/min |

| Output | 40–50 Kg/h | 80–120 Kg/h | 180–200 Kg/h |

| Screen Mesh Size | 40 mm | 50 mm | 50 mm |

| Motor Power | 5.5 kW | 15 kW | 22 kW |

| Heating Power | 4 kW | 10 kW | 14 kW |

| Crushing Power | 1.5 kW | 2.2 + 2.2 kW | 8.8 kW (4x2.2) |

| Dimensions (mm) | 1410×1085×1600 | 2030×1400×2050 | 3400×1880×2550 |

| Weight | 1000 Kg | 1800 Kg | 2500 Kg |

Warranty & Installation

1-Year Limited Warranty

Every EPS Foam Melting Machine includes a comprehensive one-year limited warranty, covering all mechanical components against manufacturing defects.

Commissioning & Support

We provide full installation guidance, either remotely or on-site by experienced engineers. We also offer operational consultancy to ensure your recycling line runs smoothly.

Frequently Asked Questions

What types of foam is this machine primarily designed for?

This machine is primarily designed for EPS (Expanded Polystyrene) foam, commonly found in packaging materials, fish boxes, and insulation boards. It effectively densifies these loose materials into solid blocks.

What volume reduction can I expect?

Our melting machine can achieve a remarkable volume reduction ratio of up to 90:1. This means a truckload of loose foam can be compressed into a single pallet of ingots.

How does the temperature control work?

The automatic system maintains optimal melting temperatures to prevent overheating (which degrades plastic properties and causes fumes) or underheating. This ensures high-quality ingots that fetch better market prices.

What output capacities are available?

We offer models ranging from smaller 40-50 kg/h units (GL-HM100) to high-capacity 180-200 kg/h industrial systems (GL-HM400) to match your specific waste volume.

Start Recycling Your EPS Foam Today

Save on storage, reduce transport costs, and turn your waste into revenue. Contact us for the latest pricing and specs.