3D Filament Extruder for Recycled Polymer Feedstock

Compact twin‑screw filament extruder for small‑batch material reuse. Supports common polymers (PLA, ABS, TPU, Nylon, PC and more) with 0–350°C heating, VFD speed control, and 0.1–3 kg/h output (material dependent).

Compatibilidad de materiales

Suitable for common plastics used in prototyping, functional parts, and recycled feedstock streams.

3D Printing Polymers

PLA, ABS, TPU, Nylon, PC, and related blends. For consistent filament, keep material dry and avoid mixing incompatible polymers.

General Plastics

PE, PP, PVC and similar commodity plastics. Output stability depends on melt behavior and feedstock cleanliness.

Recycled Feedstock

Regrind or flakes prepared from prints, caps, and bottles. Screening and drying improve hopper feeding and reduce diameter variation.

Process Notes

Remove metal, stones, and abrasive dirt. Moisture is a common failure mode for filament consistency—store sealed and dry before extrusion.

Especificaciones clave

Core performance and mechanical parameters for equipment comparison and setup planning.

| Materiales aplicables | PE / PP / PVC / PLA / PC / TPU / ABS / Nylon |

| Capacidad de salida | 0.1–3 kg/h (material dependent) |

| Screw Type | Twin‑screw extrusion |

| Diámetro del tornillo | 21 mm |

| Velocidad del tornillo | Up to 15 rpm |

| Screw L/D Ratio | 11:1 |

| Screw/Barrel Material | 38CrMoAlA (nitrided, polished) |

| Nitrided Layer Thickness | 0.5–0.7 mm |

| Surface Hardness | HV 850–940 |

| Heating Zones | 3 zones |

| Max Heating Temperature | 0–350°C |

| Potencia de calefacción | 1000 W |

| Potencia del motor | 180 W |

| Sistema de control | VFD (variable‑frequency) control |

| Fuente de alimentación | 110 V / 220 V, 50/60 Hz, single‑phase (customizable) |

| Line Center Height | 300 mm |

| Discharge Orientation | Left / right (configurable) |

| Installation Footprint (L × W × H) | 1.8 m × 0.2 m × 1.0 m |

| Approx. Weight | 47 kg + 21 kg |

Note: Specifications shown are for reference only. Contact us to confirm your configuration and request the complete specification sheet.

Temperature and Speed Control

Control melt stability and output consistency with multi‑zone heating and VFD speed regulation.

0–350°C heating range

Designed for common thermoplastics used in 3D printing and recycled applications. Setpoints depend on polymer grade and moisture level.

3 heating zones

Multi‑zone heating supports more stable melt development from feed to die, reducing risk of partial melting and flow instability.

VFD speed control

Variable‑frequency control adjusts screw speed to match melt behavior and puller/winder conditions for a smoother, repeatable process.

110 V / 220 V options

Voltage is customizable for local mains. Confirm your region and plug type when checking availability and pricing.

Recycled Filament Workflow

A practical setup for turning waste prints and plastic scrap into usable extrusion feedstock.

If your input is 3D printing scrap, bottle caps, or prepared PET bottles, start with consistent feedstock. Shredding to a manageable regrind size and keeping material dry significantly improves hopper feeding and melt stability. For a matching size‑reduction step, see the Mini Desktop Shredder.

Typical workflow: (1) prepare and dry feedstock, (2) extrude with stable temperature and screw speed, (3) cool and guide filament, and (4) wind onto a spool. For best results, avoid mixed polymers and keep regrind clean of abrasives and metal.

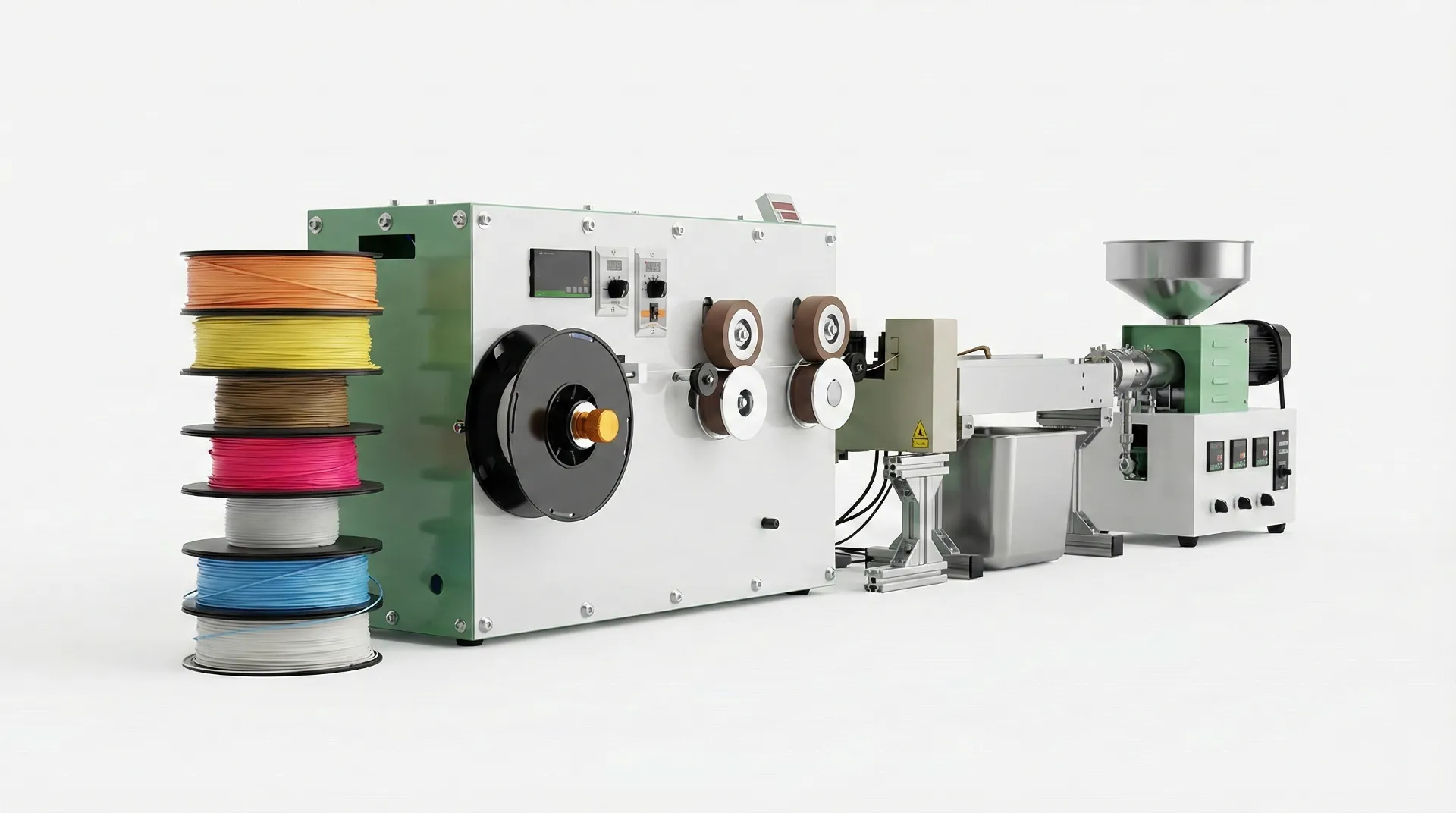

Fotos

Product and filament references for visual confirmation.

Use these photos to confirm the overall layout and to reference typical filament presentation. If you plan to run recycled feedstock, the most important factor is consistent input preparation—clean, dry material with stable particle size. Pairing the extruder with a dedicated size‑reduction step can improve feeding and melt stability. If you are building a closed‑loop workflow for 3D printing waste, start with the matching desktop shredder before extrusion. For order validation, request a short sample run on your target polymer.

Preguntas frecuentes

Selection and setup questions for small‑batch filament production.

Which materials are supported?

Applicable materials include PE, PP, PVC, PLA, PC, TPU, ABS, and Nylon. Filament stability depends on polymer grade, moisture control, and whether you keep input material sorted by polymer type.

What output rate should I expect?

Typical output is 0.1–3 kg/h depending on polymer type, temperature profile, screw speed, and how consistently feedstock enters the extruder.

What is the heating temperature range?

The heating range is 0–350°C with three heating zones. Actual setpoints depend on polymer type and moisture level.

Can it run on 110V?

Yes. Power supply is customizable (110 V / 220 V, 50/60 Hz, single‑phase). Confirm your region and plug type when checking price.

Can I run recycled regrind or flakes?

Yes, if feedstock is prepared properly. Dry the material, keep particle size consistent, and remove contaminants. Many users pair a shredder to create uniform regrind before extrusion.

What helps maintain consistent filament quality?

Use dry, consistent input material, keep temperature stable across the three zones, and tune screw speed via VFD control to match cooling and winding. Avoid mixing incompatible polymers and keep feedstock free of abrasives.

Pricing and Availability

Check price, voltage option, and your target materials before ordering.

To confirm the right configuration and pricing, share your target polymer(s), expected output rate (0.1–3 kg/h range), and your local power supply requirement (110 V or 220 V). If you plan to process recycled feedstock, include the feed form (regrind/flakes) and whether you will dry the material.

- Materials: PLA / ABS / TPU / Nylon / PC, or PE / PP / PVC

- Feed form: pellets, regrind, or flakes

- Output target: 0.1–3 kg/h (material dependent)

- Power: 110 V / 220 V, 50/60 Hz (customizable)

- City/country for shipping estimate and lead time