PET Plastic Recycling Machine: A Complete Buyer’s Guide

A PET plastic recycling machine is the core component of any successful plastic reclamation operation, transforming post-consumer bottles into valuable, reusable materials. As global demand for recycled PET (rPET) grows, understanding the technology, process, and economic factors involved is critical for businesses looking to enter or expand in this sector. This guide provides a detailed overview of the entire PET recycling process, the specific machinery required at each stage, and key considerations for making a sound investment.

Polyethylene terephthalate (PET) is one of the most commonly used plastics, especially for beverage bottles and food containers, due to its strength, light weight, and clarity. However, its widespread use also contributes significantly to plastic waste. Recycling PET not only mitigates environmental damage but also creates a sought-after commodity. According to a report by Grand View Research, the global PET recycling market is projected to continue its significant growth, driven by sustainability goals and regulatory pressures.

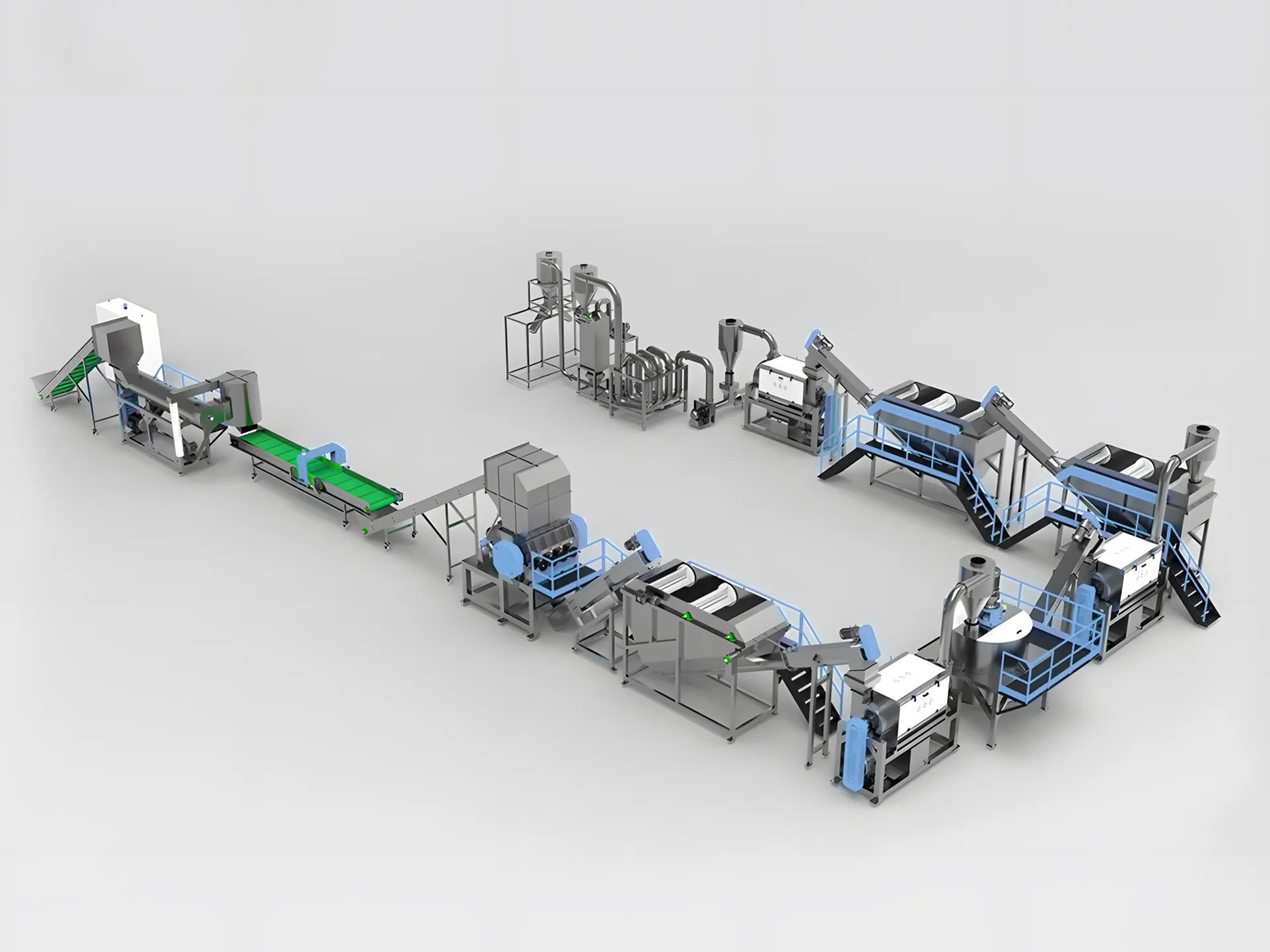

The Step-by-Step PET Recycling Process and Essential Machines

Transforming a bale of used PET bottles into high-quality rPET flakes or pellets involves a multi-stage process. Each stage requires specialized machinery designed for a specific function. A complete setup is often referred to as a PET bottle washing line.

Stage 1: Baling, De-baling, and Sorting

The journey begins after used bottles are collected and compressed into large bales for efficient transport. The recycling facility’s work starts here.

- Bale Breaker (De-baler): The first machine in the line is a Bale Breaker. It tears apart the compressed bales, loosening the bottles and feeding them steadily into the sorting line. This ensures a consistent flow of material for the subsequent stages.

- Sorting Systems: This is a crucial step to remove contaminants. Contamination from other plastics (like PVC), metals, paper, and food residue can drastically reduce the quality of the final rPET.

- Manual Sorting Conveyor: Workers stand alongside a conveyor belt to visually inspect and manually remove large contaminants and non-PET materials.

- Trommel Screen: A large rotating drum with holes of a specific size. It helps to sift out smaller contaminants like dirt, sand, and loose bottle caps.

- Optical Sorters: Advanced systems use near-infrared (NIR) technology to automatically identify and separate different types of plastics and colors. This is essential for producing high-purity, color-sorted rPET flakes.

Stage 2: Size Reduction – Shredding and Grinding

Once sorted, the whole bottles must be broken down into smaller, manageable pieces called “flakes.”

Key Machinery: Plastic Shredders and Granulators

- Plastic Shredder: A heavy-duty machine used for initial size reduction. A single-shaft shredder is often used to tear the bottles into rough, smaller pieces. This pre-shredding step reduces the strain on the granulator.

- Plastic Granulator (or Crusher): The pre-shredded material or whole bottles are fed into a granulator. This machine uses high-speed rotating blades to chop the plastic into uniform flakes, typically 10-15mm in size. The size is controlled by a screen with specific hole diameters. This process is often performed wet to pre-wash the material and reduce blade wear.

Stage 3: Intensive Washing and Separation

This is arguably the most critical phase for determining the final quality of the rPET. The goal is to remove all surface contaminants like glue, labels, and leftover liquids.

Key Machinery: The Washing Line Components

- Friction Washer: A high-speed washer with rotating paddles that scrub the flakes against each other and a screen, effectively removing dirt and labels.

- Float-Sink Tank: This tank uses the principle of density. It’s filled with water, where the heavier PET flakes (density ~1.38 g/cm³) sink to the bottom, while the lighter label and cap materials (polypropylene and polyethylene, density <1 g/cm³) float to the top. Paddles skim off the floating contaminants, achieving a high degree of separation.

- Hot Washer: To remove stubborn glue and oils, flakes are washed in hot water (around 85-95°C) mixed with a caustic soda solution. This process is vital for applications requiring high purity, such as food-grade packaging. The U.S. Food and Drug Administration (FDA) has specific guidelines for processes that produce post-consumer recycled plastics for food contact.

Stage 4: Drying

Before the flakes can be processed further or sold, they must be thoroughly dried. Any residual moisture can cause defects in the final products.

Key Machinery: Drying Systems

- Centrifugal (Mechanical) Dryer: This machine uses centrifugal force to spin the water off the surface of the flakes at high speeds, removing the majority of the moisture quickly and efficiently.

- Thermal (Hot Air) Dryer: A stream of hot, dry air is passed through the flakes, typically in a zig-zag pipeline system. This removes the remaining moisture, bringing the final moisture content down to less than 1%.

Stage 5: Pelletizing (Optional but Recommended)

While high-quality flakes can be sold directly, many manufacturers prefer rPET in pellet form. Pellets are easier to handle, transport, and feed into production machinery like injection molders or extruders.

Key Machinery: Plastic Pelletizer

- Extruder: The clean, dry flakes are fed into an extruder. A rotating screw melts and homogenizes the plastic, pushing it through a filtration system to remove any final impurities.

- Pelletizing Die and Cutter: The molten plastic is forced through a die plate, forming spaghetti-like strands. A high-speed cutting blade then slices these strands into small, uniform pellets, which are immediately cooled by water.

How to Select the Right PET Recycling Machine for Your Business

Choosing the correct equipment depends on several factors specific to your operational goals. Answering these questions will help you and your equipment supplier, like Rumtoo Machine, design the most suitable system.

1. Analyze Your Input Material

The quality of your raw material (the collected bottles) will dictate the complexity of your washing and sorting line.

- Source: Are you sourcing from a clean, deposit-based system or post-consumer municipal waste? Municipal waste is typically more contaminated.

- Contamination Level: High levels of dirt, non-PET plastics, and other debris will require more robust sorting and washing stages, such as multiple float-sink tanks or an advanced optical sorter.

2. Define Your Desired Output Quality

The end-use of your rPET determines the required purity and, therefore, the necessary machinery.

- General Purpose Flakes: For applications like fiberfill or strapping, a standard washing line may be sufficient.

- Bottle-to-Bottle (Food-Grade) Pellets: This is the highest-value output. It requires an extensive washing process, including a thorough hot wash, and often a pelletizing system with advanced filtration. As noted by the U.S. Environmental Protection Agency (EPA), recycling plastics conserves natural resources and energy. Achieving food-grade quality maximizes this benefit.

3. Determine Required Capacity (Throughput)

Capacity is measured in kilograms or pounds per hour (kg/hr or lbs/hr). Your choice will depend on your business scale, available raw material, and market demand. Lines can range from small-scale (300-500 kg/hr) to large industrial operations (2,000 kg/hr or more). Be sure to plan for future growth.

4. Evaluate Automation, Energy, and Water Consumption

Modern PET plastic recycling machines offer varying levels of automation.

- Automation: Automated sorting and monitoring systems can reduce labor costs and improve consistency but require a higher initial investment.

- Energy and Water Use: Look for machines with energy-efficient motors and closed-loop water treatment systems. Reducing water consumption not only lowers operational costs but is also a key part of a sustainable operation.

High-Value Applications of Recycled PET (rPET)

The output from a PET recycling plant is a versatile raw material with broad applications, closing the loop in a circular economy.

- Bottle-to-Bottle Production: The most circular application, where rPET pellets are used to manufacture new beverage bottles and food containers.

- Polyester Staple Fiber (PSF): rPET flakes are melted and spun into fine fibers used for textiles (clothing, fleece jackets), carpets, and stuffing for pillows and duvets.

- Strapping: High-strength polyester strapping, used in packaging and logistics, is a major market for rPET.

- Sheet and Film: rPET can be extruded into sheets for thermoforming applications like clamshell containers and packaging trays.

- Building Materials: Recycled PET is used in some construction applications, such as insulation materials and plastic lumber.

Partner with Rumtoo Machine for Your Recycling Success

Investing in a PET plastic recycling machine is an investment in a profitable and sustainable future. The key to success lies in choosing durable, efficient equipment tailored to your specific needs. At Rumtoo Machine, we provide complete, end-to-end solutions for plastic recycling. Our team of experts can help you design a plant that matches your input materials and output quality goals, ensuring a high return on your investment.

Ready to turn plastic waste into a valuable resource? Contact us today to discuss your project, and let us help you build a successful recycling operation. Explore our full range of plastic recycling solutions to learn more.