100-Ton Fully Automatic Horizontal Baler

Transform high volumes of waste into dense, manageable bales with our state-of-the-art baler. Drastically reduce labor, storage, and transport costs.

Engineered for Maximum Efficiency

Our baler is designed from the ground up to automate your waste management, boost productivity, and ensure reliable, long-term performance.

Fully Automatic Operation

From compressing and strapping to bale ejection, the PLC-controlled system minimizes manual labor and maximizes throughput.

Energy-Saving Hydraulics

Equipped with advanced German hydraulic technology and a dual-motor design that optimizes energy use and reduces operational costs.

User-Friendly Controls

Features one-button operation and a simple touch screen for easy adjustments, real-time feedback, and fault diagnosis.

Robust & Reliable

A heavy-duty frame and unique cutter design ensure longevity and consistent performance, even under continuous, heavy use.

Turn Waste Management Costs into Profit

Loose waste material is expensive to handle, store, and transport. Our automatic baler is the ultimate solution to streamline your operations.

Problem: High Labor & Disposal Costs

Manually handling loose waste is labor-intensive. High-volume, low-density materials lead to frequent, expensive hauling fees.

Solution: Automate & Compact

Our baler fully automates the compaction process. It creates dense, uniform bales that drastically cut labor and reduce transport costs by up to 75%.

Problem: Inefficient Use of Space

Piles of loose cardboard, plastic, or paper consume valuable floor space, creating a disorganized and unsafe working environment.

The 4-Step Automatic Baling Cycle

Our system is designed for a seamless, "hands-off" operation from loose material to a finished, ready-to-ship bale.

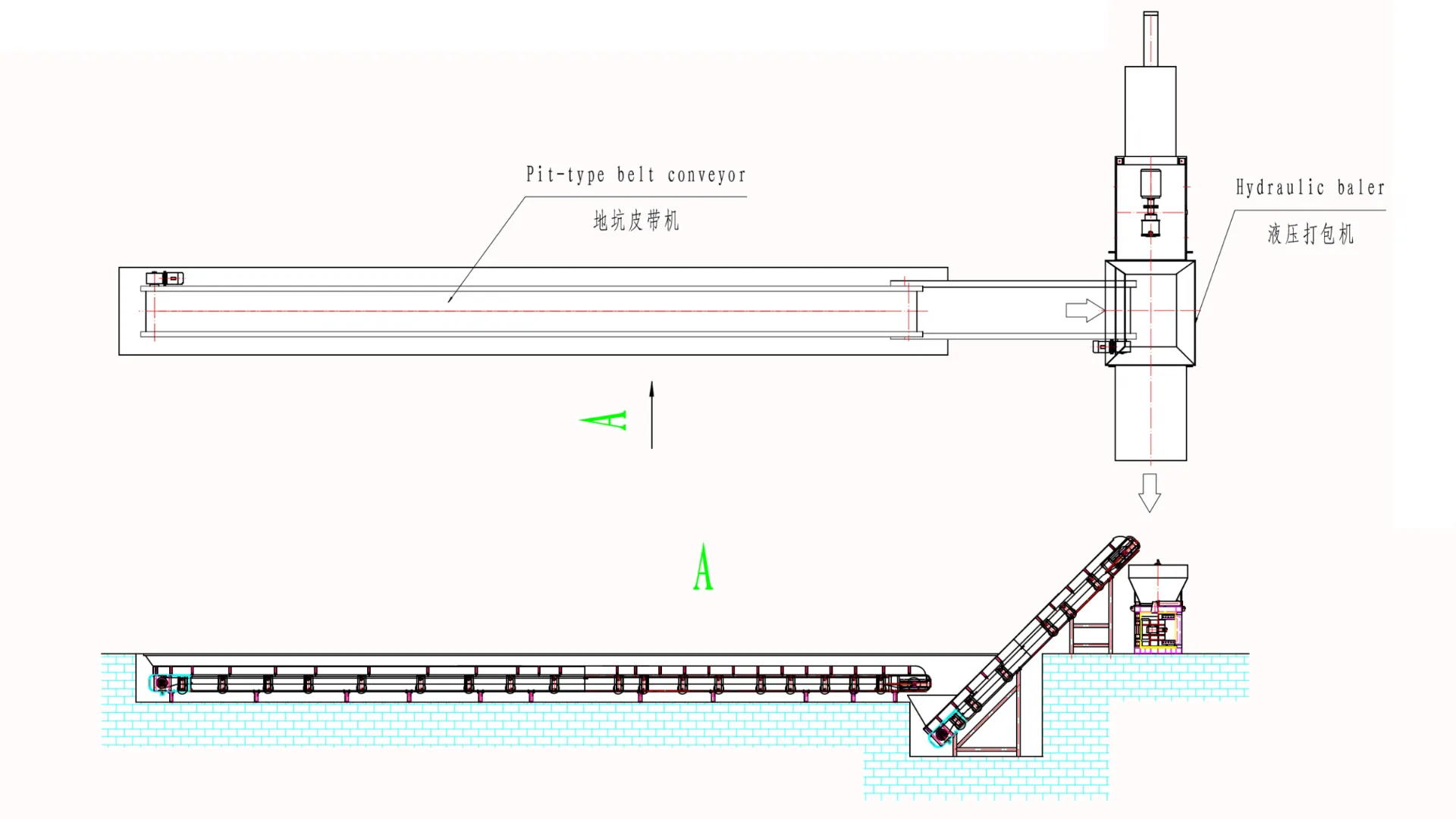

1. Automatic Feeding

An optional conveyor feeds material into the hopper. Photoelectric sensors control the belt to ensure optimal, continuous loading.

2. High-Force Compression

A powerful hydraulic ram automatically compresses the material with up to 100 tons of force against a solid steel plate.

3. Automatic Strapping

Once the desired bale length is reached, the machine automatically threads, ties, and cuts the strapping wires around the bale.

4. Bale Ejection

The completed, dense bale is then automatically ejected from the chamber, ready for storage or transport.

Machine Showcase

Versatile Solution for High-Volume Waste

Ideal for any facility that generates significant quantities of recyclable materials and seeks to optimize their handling process.

Distribution & Logistics Centers

Effortlessly handles massive volumes of cardboard (OCC) and plastic shrink wrap, turning a waste stream into a revenue source.

Manufacturing & Packaging Plants

Perfect for baling waste paper, cardboard cut-offs, plastic packaging, and PET bottles directly from production lines.

Large-Scale Recycling Facilities

A cornerstone machine for MRFs and waste transfer stations to process and prepare materials for shipment to end-users.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | HFA-100T |

| Press Force | 100 Tons |

| Bale Size (W*H) | 1100 * 1200 mm (Customizable) |

| Bale Weight (Cardboard) | 800 - 1100 kg |

| Motor Power | 45 + 5.5 KW |

| Capacity (Cardboard) | 8 - 12 Tons/hr |

Frequently Asked Questions

What materials can this baler process?

It is highly versatile and can process a wide range of materials, including waste paper, cardboard, all types of plastics (PET bottles, film), and textiles. It is ideal for various industries with diverse waste streams.

How does the automatic feeding conveyor improve efficiency?

The optional conveyor uses sensors to monitor the material level in the hopper. It automatically starts and stops to ensure a consistent, optimal flow of material into the baler, which maximizes throughput speed without requiring manual intervention.

How easy is it to maintain the baler?

The baler is designed for easy maintenance. The PLC program includes an automatic fault diagnosis function, and the simple, robust frame provides easy access for service. We also provide detailed operation and maintenance manuals to facilitate routine checks.

Automate Your Waste Handling Process

Contact us today to learn how our 100-ton automatic baler can transform your operational efficiency and profitability. Get a detailed proposal and pricing now.