Looking to maximize efficiency and quality in your polymer processing operations? Energycle delivers cutting-edge co-rotating twin screw extruders engineered for precision compounding, mixing, and processing across plastics, chemicals, food production, and advanced materials. With proven expertise in extrusion technology and a customer-first approach, we help manufacturers worldwide achieve superior production results.

What Is a Co-Rotating Twin Screw Extruder?

A co-rotating twin screw extruder features two intermeshing screws that rotate in the same direction within a heated barrel. This closely intermeshing design creates exceptional self-wiping action and uniform material distribution, making it the industry standard for complex compounding applications.

Key advantages include:

- Superior mixing capability – Both distributive and dispersive mixing ensure homogeneous blending of polymers, additives, fillers, and reinforcements

- Excellent self-cleaning – Co-rotating intermeshing screws prevent material buildup and reduce degradation risk

- Flexible processing – Modular screw design adapts to diverse materials and formulations

- Efficient devolatilization – Multiple venting zones effectively remove moisture and volatiles

Why Choose Energycle Co-Rotating Twin Screw Extruders?

1. Versatile Applications Across Multiple Industries

Our twin screw extruders excel in demanding production environments:

- Plastics compounding – Masterbatch production, polymer blends, filled compounds

- Chemical processing – Reactive extrusion, polymer modification, additives dispersion

- Powder coatings – Uniform pigment and resin blending

- Food processing – Snack foods, pet food, textured proteins

- Wood-plastic composites (WPC) – Decking, profiles, construction materials

- Pharmaceutical applications – Hot melt extrusion for drug delivery systems

2. Advanced Engineering & Modular Design

Modular “Building Block” Screw Configuration

Energycle extruders feature interchangeable screw elements that you can customize for your specific process requirements. This flexibility means:

- Easy adaptation to new formulations without equipment replacement

- Simplified maintenance and faster changeovers

- Optimized processing for each unique application

- Cost-effective process development and scaling

RTM Series Performance Range

Our comprehensive product line spans screw diameters from 20mm to 200mm, with configurations tailored to your throughput needs:

- Laboratory scale (20-35mm) – R&D, pilot testing, small-batch production

- Production scale (50-200mm) – Industrial manufacturing with outputs up to several tons per hour

- Customized torque classes – Match motor power and gearbox design to material viscosity and processing intensity

3. Superior Plasticizing & Compounding Performance

Closely intermeshing screw geometry delivers:

- Complete self-wiping action – Screws continuously clean each other, preventing material stagnation

- Positive conveying – Consistent material flow regardless of viscosity changes

- Intensive mixing zones – Kneading blocks and mixing elements ensure thorough dispersion

- Precise residence time control – Narrow residence time distribution protects heat-sensitive materials

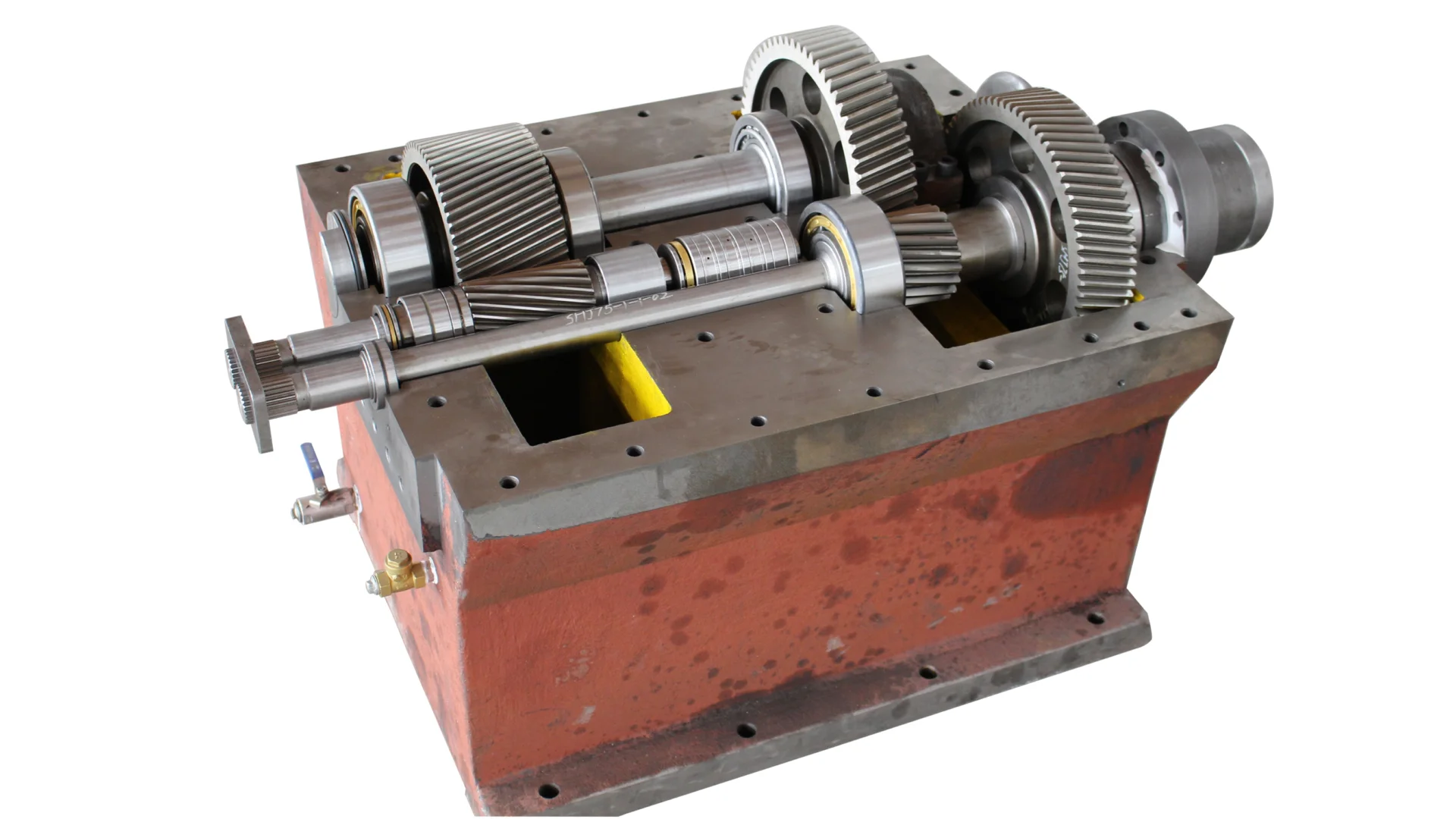

4. Robust Power Transmission System

Reliability starts with premium components. Energycle extruders feature:

- Heavy-duty gearbox with precision-ground, case-hardened gear teeth for smooth torque distribution

- High-quality imported bearings rated for continuous operation under demanding loads

- Integrated lubrication system with temperature monitoring for extended component life

- Overload protection to safeguard your investment during unexpected processing conditions

5. Premium Materials & Construction

Every component is built for durability:

- Hardened, nitrided barrel sections resist wear from abrasive fillers

- Bimetallic barrel liners (optional) for extreme wear resistance with glass fiber or mineral-filled compounds

- Sturdy welded steel base with precision adjustment pads ensures proper alignment

- Stainless steel barrel insulation covers maintain thermal efficiency and operator safety

6. Advanced Screen Changer Technology

Maintain continuous production with our innovative melt filtration systems:

- Hydraulic slide-plate screen changers – Quick, non-stop screen changes without production interruption

- Continuous belt screen changers – Automatic filtration for ultra-clean output in critical applications

- Basket-type screen changers – Cost-effective solution for standard filtration needs

Each system integrates seamlessly with downstream pelletizing, profiling, or sheet extrusion equipment.

High-precision gearbox internals engineered for reliable torque distribution and extended service life

Co-Rotating vs. Counter-Rotating: Understanding the Difference

While both configurations serve extrusion needs, co-rotating twin screw extruders offer distinct advantages:

| Feature | Co-Rotating | Counter-Rotating |

|---|---|---|

| Self-wiping | Excellent – screws clean each other completely | Limited – material can accumulate in intermesh zone |

| Mixing intensity | Superior for both distributive and dispersive mixing | Better suited for gentle mixing |

| Modular flexibility | Highly modular – easy screw reconfiguration | Limited modularity |

| Applications | Compounding, reactive extrusion, devolatilization | Profile extrusion, pipe production |

| Material versatility | Handles wide viscosity range | Best for consistent viscosity materials |

For polymer compounding, masterbatch production, and complex formulations, co-rotating designs deliver unmatched performance.

Your Trusted Partner in Extrusion Technology

Over 20 years of specialized expertise positions Energycle as your reliable manufacturing partner. We understand that every application presents unique challenges—from achieving tight color tolerances in masterbatch production to optimizing throughput in recycled resin compounding.

Our engineering team works closely with you to:

- Select optimal screw configurations for your materials

- Design processing zones that balance mixing quality and energy efficiency

- Scale processes from laboratory to full production

- Provide ongoing technical support and process optimization

Whether you’re processing engineering plastics, creating color masterbatches, compounding glass-filled polymers, or developing innovative bio-based materials, Energycle co-rotating twin screw extruders deliver the precision and reliability your operation demands.

Ready to Elevate Your Compounding Operations?

Let’s discuss how Energycle technology can solve your specific processing challenges. Our application engineers are ready to review your material requirements, production goals, and technical specifications.

Contact the Energycle team today to explore extruder configurations tailored to your needs. We’re committed to helping you achieve:

- Higher product quality with improved consistency

- Increased production efficiency and reduced waste

- Lower total cost of ownership through durable design

- Faster time-to-market for new formulations

Transform your polymer processing capabilities with Energycle – where engineering excellence meets manufacturing reliability.