In a plastic washing line, the centrifugal dryer is the handoff between wet processing and final drying/pelletizing. It removes free surface water mechanically, which reduces the load on thermal dryers and helps you hold more stable extrusion conditions.

Installation is not only “bolt it down and start.” Placement, feed control, air handling, and water discharge design decide whether the dryer runs smoothly or becomes the bottleneck.

Quick Takeaways

- Put the dryer after the last effective wash/rinse step, before any thermal drying.

- Feed it with a steady, metered flow; surges cause wet output and vibration.

- Treat air exhaust and water discharge as part of the dryer, not as afterthought piping.

- Plan access for screen inspection and cleaning; screens are consumables.

- Define moisture targets and where you will measure them before you size the hot-air dryer or pelletizer.

1) Where the Centrifugal Dryer Fits in the Line

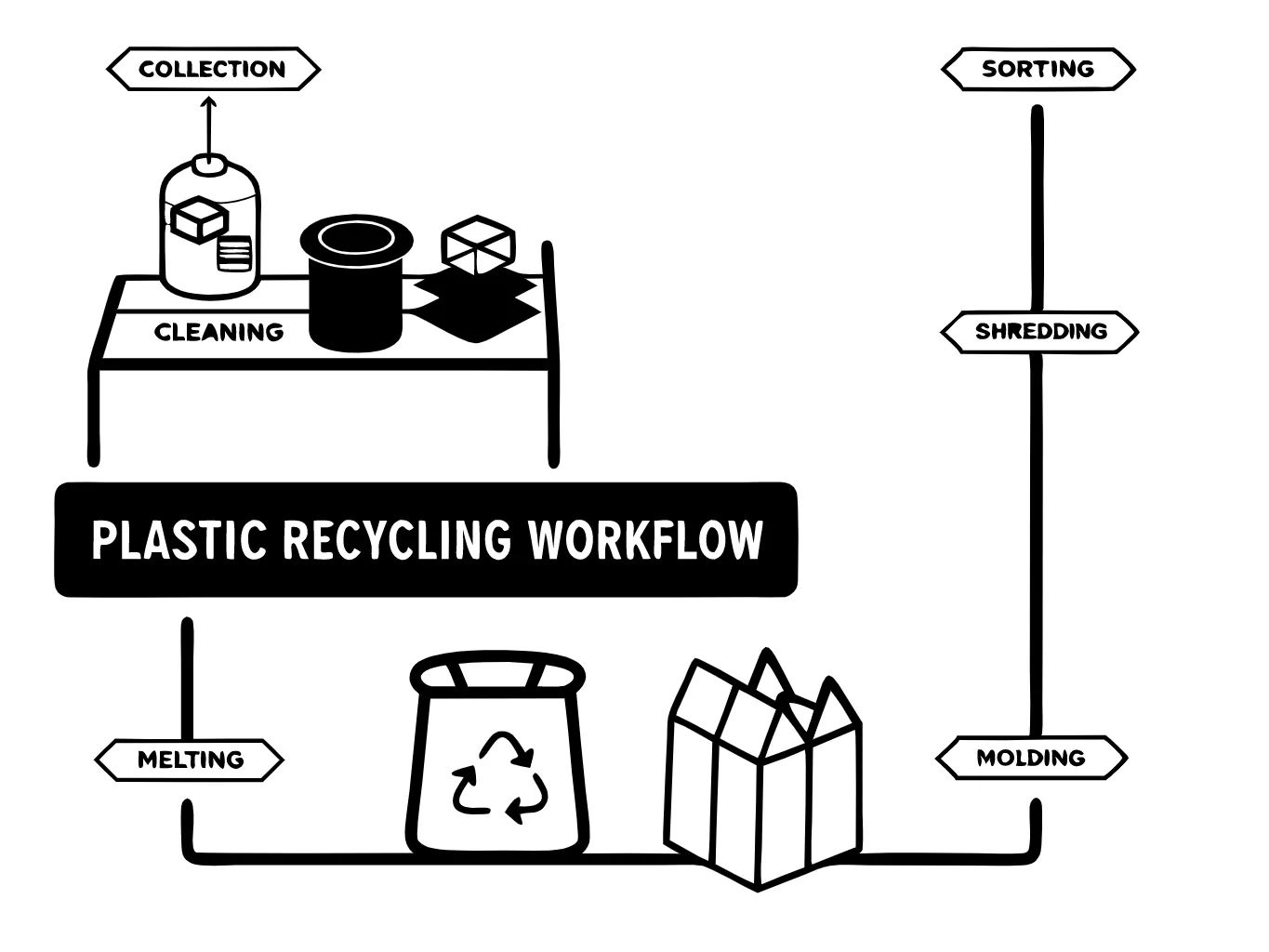

Most lines place the dryer after friction washing and sink/float separation:

- size reduction (shredder/granulator)

- washing and separation

- centrifugal drying (mechanical dewatering)

- thermal drying / storage silo

- extrusion and pelletizing (if the line produces pellets)

If you are running a full recycling washing system, the dryer is typically one of the last machines before hot air drying or storage.

1A) What the Dryer Does (And What It Does Not Do)

A centrifugal dryer is a mechanical dewatering step. It is great at removing free surface water, but it is not a substitute for thermal drying when:

- flakes leave the washer very hot and hold moisture in folds/fines

- your downstream extrusion is sensitive to residual moisture

- you need a tighter moisture window for stable pellet quality

Treat the dryer as the bridge that reduces the thermal load. Then design the hot-air dryer (or storage + conditioning) around the moisture level you need at extrusion feed.

2) Feed System: Prevent Surges and Bridging

The dryer performs best with steady loading. Two problems cause most performance complaints:

A) Surging feed – Example: a wet crusher dumps a slug of flakes, then starves. – Result: inconsistent “bed depth” inside the dryer; moisture swings.

Fixes – add a buffer hopper with controlled discharge – run the feed auger/conveyor on a VFD so operators can tune throughput

B) Uneven feed distribution – Result: one side of the rotor carries more load; vibration increases.

Fixes – center the inlet, or use a spreader plate inside the hopper – confirm the feed screw does not discharge directly onto one side of the rotor

3) Water Discharge: Keep It Free-Flowing

Centrifugal dryers throw water out at high velocity. If the drain line creates backpressure, water can re-enter the chamber and raise outlet moisture.

Design checks: – use a short, straight drop to a trench or collection tank when possible – avoid tight elbows and long horizontal runs that trap sludge – provide access points for cleaning (paper fines and label glue build up over time)

4) Air Handling: Don’t Choke the Machine

The rotor also moves air. Exhaust restrictions can raise internal pressure and reduce drainage efficiency.

Good practice: – size the exhaust duct to the dryer’s design airflow – route exhaust to a cyclone or filter if you carry fines – keep inspection doors accessible to remove buildup

4A) Fines Management: Protect Downstream Water and Air Systems

Film flakes, labels, paper fibers, and glue carry fines that can migrate into your drain loop and exhaust path. Plan for:

- fines capture (cyclone, filter, or settling) to reduce buildup

- clean-out access at elbows, transition pieces, and collection bins

- operator checks (a simple daily inspection prevents a week of compounding restrictions)

This does not need to be complex, but it does need to be designed. A dryer that “works” for two weeks and then clogs will fail your uptime target.

5) Commissioning Checklist

Use this checklist during installation and the first production run.

| Item | What to Verify | Why It Matters |

|---|---|---|

| Foundation and leveling | Machine sits flat; fasteners torqued; guards installed | Reduces vibration and premature bearing wear |

| Feed control | Stable mass flow without surges | Stabilizes moisture and motor load |

| Drain line | Free-flowing discharge without backpressure | Prevents re-wetting and flooding |

| Exhaust ducting | No restrictions; access for cleaning | Supports stable airflow and water separation |

| Screen inspection | Screen is correct type and securely seated | Controls carryover and protects downstream water treatment |

6) Troubleshooting the Two Most Common Issues

“Flakes are still wet”

Start with: – screen blinded by fines/labels – drain line partially blocked – feed rate surging (dryer alternates between overload and underload)

“The dryer vibrates more over time”

Start with: – rotor buildup (sticky fines) – uneven wear on paddles or screen supports – bearing condition and lubrication

7) Sizing and Integration Checks Buyers Often Miss

Before you purchase, ask the supplier to confirm these integration points in writing:

| Integration Question | What to Confirm | Common Failure Mode |

|---|---|---|

| What is the inlet moisture range? | Expected moisture after your last wash/rinse step, including seasonal variation | Dryer is sized for “best case,” then struggles in real operation. |

| What is the outlet moisture target? | Target moisture and measurement point (after dryer discharge, before hot-air dryer, or at silo) | Hot-air dryer and pelletizer are sized on assumptions, not measurements. |

| How will you meter feed? | Buffer hopper + controlled discharge (VFD screw/valve) | Surging causes wet output, high amps, and vibration events. |

| What is the drain and exhaust plan? | Short drain drop, clean-out access, and exhaust sized to design airflow | Backpressure and restriction re-wet flakes and reduce separation. |

| What is the maintenance access path? | Safe access for screen, rotor, and bearings with guarding and LOTO | Cleaning is skipped because it is slow or unsafe, so problems compound. |

If you want a dryer sized and integrated for your target output, Energycle can configure it as part of a complete line via its contact page.

FAQ (Real Procurement Questions)

1) How do I choose the right centrifugal dryer size for my washing line?

Start from your real wet throughput and your moisture conditions, not the advertised dry kg/h. Ask your supplier to state the assumed inlet moisture range, the target outlet moisture, and the target polymer stream (film flakes behave differently than rigid flakes). Then confirm the feed method (steady metered flow) and the discharge path (no backpressure). If your washer throughput varies by shift, the dryer must tolerate short surges without long wet “tails.” A good quote ties dryer size to test conditions and includes motor load expectations, screen type, and the cleaning interval expected on your contamination window.

2) What moisture level should I target after the centrifugal dryer?

There is no universal number because it depends on polymer, downstream storage, and how sensitive your extrusion is to residual moisture. The practical approach is to define a moisture target where you will measure it (at dryer discharge, at hot-air dryer inlet, or at extruder feed) and then size each step to hit that target reliably. Mechanical dewatering removes free water, but fines and folded film can retain moisture. Ask the supplier what moisture window their dryer can hold at your feed condition, and how performance changes if labels, paper fibers, or fines increase.

3) Do I need a hot-air dryer if I already have a centrifugal dryer?

Often yes—especially for film streams and any pelletizing line that needs stable extrusion. The centrifugal dryer reduces free water and lowers the thermal load, but hot-air drying is how you tighten the final moisture window and stabilize the feed to extrusion or storage. If your output is sold as pellets, moisture swings can show up as unstable melt pressure, foaming, and pellet quality drift. The decision should be based on your required output spec and the measured moisture after mechanical dewatering. Ask for a simple moisture balance across the line and size hot-air drying around worst-case inlet moisture, not average days.

4) What are the most common integration mistakes that cause vibration complaints?

Most vibration issues come from uneven loading, buildup, or poor foundations. Surging feed can overload the rotor intermittently, while uneven inlet distribution loads one side more than the other. Sticky fines can accumulate and create imbalance over time, and a restricted exhaust path can change internal flow patterns. Also check installation basics: leveling, anchoring, and alignment. When you request a quote, ask the supplier to describe the required feed method, expected cleaning interval, and the foundation requirements. Confirm that guards and safe access are included so operators actually perform routine cleaning.

5) What safety standards should I consider during installation and maintenance?

Treat the dryer like any rotating machine with entanglement and energy hazards. Your installation should include proper machine guarding, clear access for inspection, and a lockout/tagout procedure for maintenance and screen cleaning. Even on small lines, safety retrofits often become a hidden cost when used equipment arrives without guarding or with outdated electrical panels. OSHA’s overviews of machine guarding and lockout/tagout provide a useful baseline for guarding and energy-control planning. Ask your supplier what interlocks and guarding are included in the scope of supply.