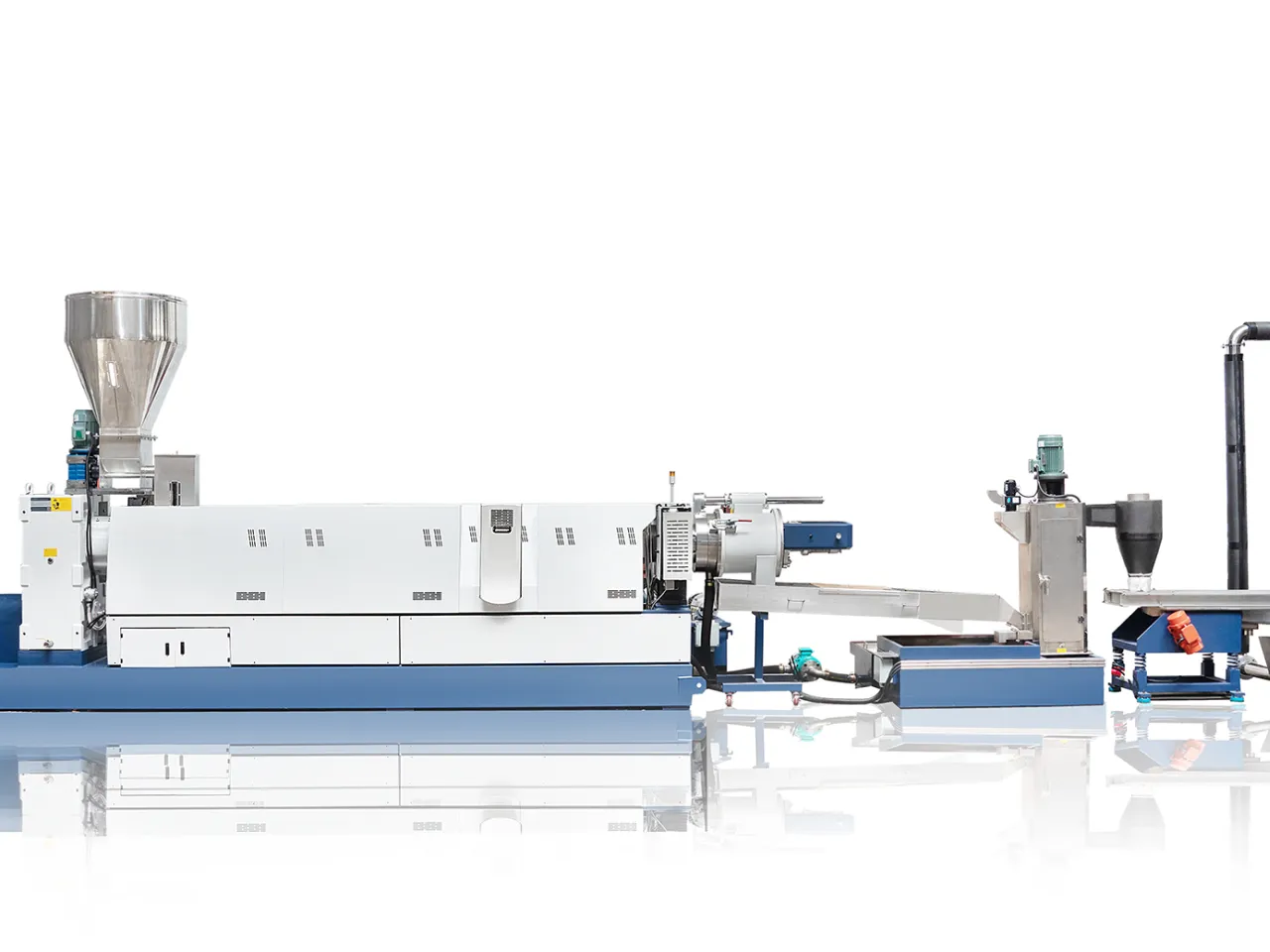

Rigid PP/HDPE Plastic Flake Pelletizing Machine

An advanced two-stage system designed to efficiently convert rigid PP and HDPE plastic flakes into high-quality, uniform pellets for injection molding and other manufacturing processes.

Get a Detailed QuoteKey Advantages of Our Rigid Pelletizing System

Two-Stage Extrusion

Ensures superior melting, plasticization, and degassing, resulting in higher quality pellets.

Intelligent Feeding

VFD-controlled screw conveyor ensures a consistent feed rate for stable, high-output production.

Advanced Filtration

Segmented, dual-stage filtration effectively removes contaminants and reduces screen changes.

Dual-Zone Degassing

Efficiently removes volatiles and moisture, ideal for printed flakes or materials with humidity.

Working Principle: A Two-Stage Process for Purity

- Consistent Feeding: Rigid plastic flakes are fed into the system by a VFD-controlled screw conveyor, ensuring a stable and automated material flow.

- First Stage Extrusion: The flakes are melted, plasticized, and undergo coarse filtration in the primary single-screw extruder.

- Second Stage Extrusion & Degassing: The melt is transferred to the secondary extruder for further homogenization. A dual-zone vacuum system removes any residual gas and moisture.

- Fine Melt Filtration: Before pelletizing, the melt passes through a high-mesh screen changer, ensuring the final product is free of fine contaminants.

- Water Ring Pelletizing: The purified melt is cut into uniform pellets by a die-face water ring system, then rapidly cooled and dried, ready for immediate use.

Technical Specifications

| Model | Screw Diameter (mm) | Output Capacity (kg/h) | Application |

|---|---|---|---|

| RPP-90 | 90/80 | 200-300 | PP/HDPE Crushed Regrind |

| RPP-100 | 100/90 | 300-400 | PP/HDPE Crushed Regrind |

| RPP-120 | 120/110 | 400-500 | PP/HDPE Crushed Regrind |

| RPP-150 | 150/140 | 600-800 | PP/HDPE Crushed Regrind |

| RPP-180 | 180/170 | 800-1000 | PP/HDPE Crushed Regrind |

*Note: Specifications can be customized. Contact us for a tailored solution.

Machine Gallery

Frequently Asked Questions

What is the advantage of a two-stage pelletizing machine?

A two-stage (or two-extruder) system provides superior degassing and filtration. The first stage handles initial melting and coarse filtering, while the second stage focuses on fine filtration and removing volatiles. This results in much purer, higher-quality pellets, especially when processing printed or slightly contaminated materials.

What types of rigid plastic can this machine process?

This rigid plastic pelletizing machine is primarily designed for pre-crushed flakes from PP (Polypropylene) and HDPE (High-Density Polyethylene) sources. This includes materials from injection molding scrap, pipes, bottles, containers, and other rigid plastic items.

What are the final pellets suitable for?

The high-quality, uniform pellets produced by this machine are an excellent raw material for various manufacturing processes. They are particularly well-suited for injection molding, extrusion of new profiles or pipes, and blow molding applications, offering a cost-effective alternative to virgin resin.

Turn Your Plastic Flakes into a Valuable Resource

Our rigid plastic pelletizing machines come with a 1-year limited warranty and can be fully customized to meet your specific operational needs. Contact us today for the latest prices and lead times.