PET Bottle Flake Pelletizer

High-efficiency Single Screw extrusion system designed to transform post-consumer PET flakes into premium-grade pellets with minimal IV loss.

Get a Specialized QuoteCore Operational Advantages

Our machine is engineered for performance, reliability, and superior output, giving you a competitive edge in the recycling industry.

Maximum Efficiency

Optimized screw design and automated feeding ensure consistent throughput and high output, converting waste into profit effectively.

Superior Pellet Quality

Advanced degassing and filtration systems produce pure, uniform pellets with excellent IV retention, ideal for high-end applications.

Robust & Reliable

Constructed with durable nitrided steel and equipped with precision controls, our pelletizer is built for continuous, long-term operation.

Sustainable Solution

Empower your business to be a key player in the circular economy by transforming plastic waste into reusable, high-grade raw materials.

Extrusion Process Flow

Our plastic recycling machine follows a meticulously engineered workflow to guarantee optimal results at every stage.

Optimized Feeding & Moisture Control

An automated feeder regulates material flow while an integrated compactor reduces moisture, preserving the PET's intrinsic viscosity (IV) for better quality.

High-Efficiency Extrusion

The precision single screw compacts, melts, and homogenizes the PET material within a temperature-controlled barrel for perfect processing conditions.

Advanced Vacuum Degassing

A double-zone vacuum system effectively removes volatile compounds and residual moisture, ensuring the production of pure, consistent pellets.

Superior Melt Filtration

Specialized melt filters eliminate contaminants, guaranteeing the purity of the final pellets and making them suitable for demanding applications.

Underwater Pelletizing System

This state-of-the-art system converts molten PET into uniform granules, which are then efficiently dried and prepared for packaging.

- Precision Single-Screw Extruder: Made from high-strength nitrided steel (38CrMoAlA) for maximum wear resistance and lifespan.

- Intelligent Temperature Control: Multiple PID control zones with high-power cooling fans maintain stable processing temperatures.

- Double-Zone Degassing: Powerful vacuum pump ensures complete removal of volatiles, crucial for high-quality PET pellet production.

- Hydraulic Screen Changer: Allows for quick and non-stop filter changes, minimizing downtime and ensuring continuous operation.

- State-of-the-Art Pelletizing: Underwater pelletizing system creates perfectly uniform, spherical granules.

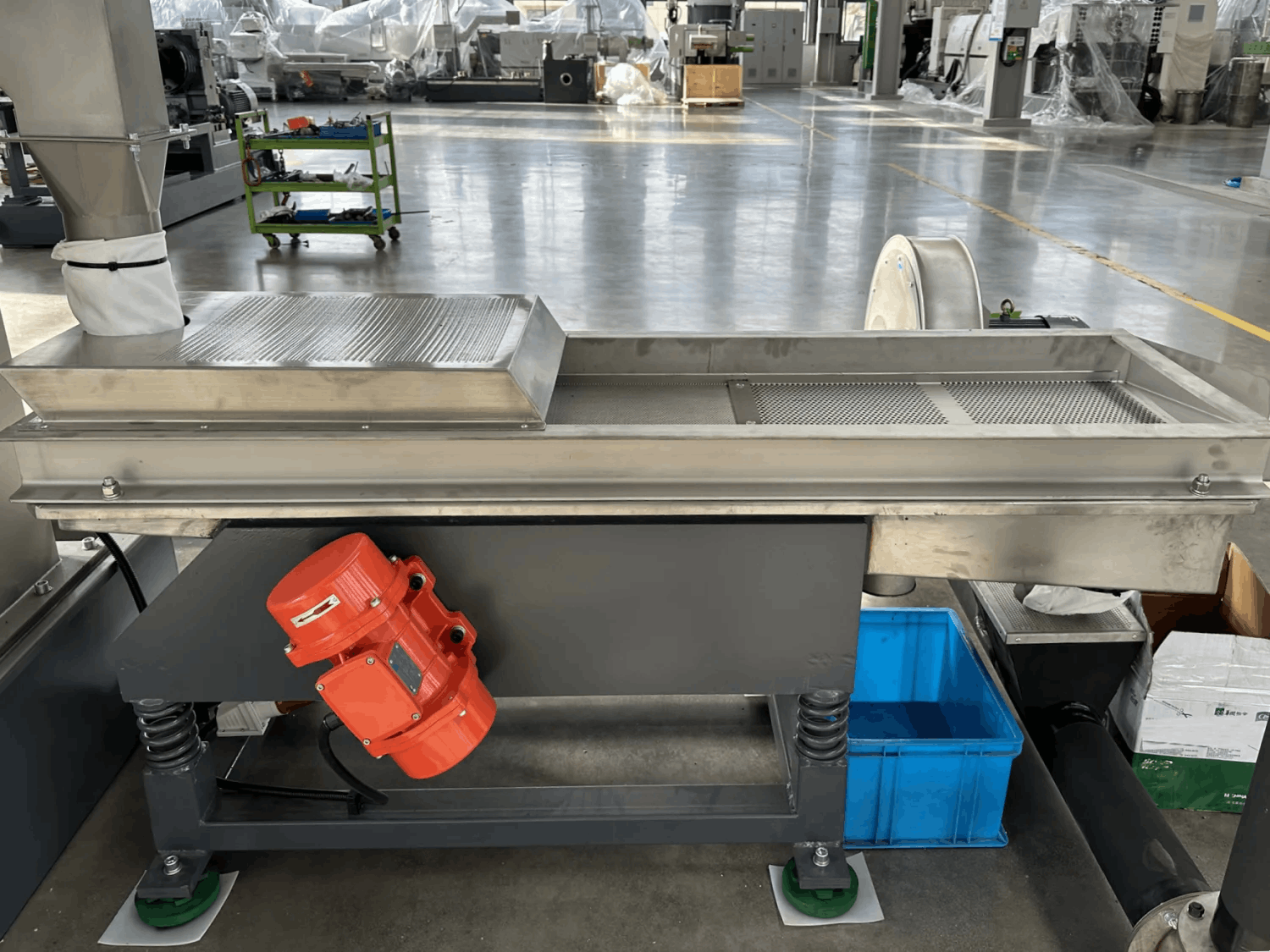

- Integrated Drying System: A centrifugal dryer and vibration sieve ensure pellets are ready for immediate packaging and use.

System Component Integration

Machine Specifications

| Model | Motor Power | Output (kg/h) |

|---|---|---|

| ERM-PET-100 | 90 KW | 300 |

| ERM-PET-130 | 132 KW | 600 |

| ERM-PET-140 | 160 KW | 900 |

| ERM-PET-160 | 250 KW | 1200 |

Equipment Operation Showcase

See our PET plastic flake pelletizer in detail and watch it in action, transforming waste into value.

Warranty & Satisfaction Guarantee

Get clear warranty terms and responsive after-sales support for your single screw PET pelletizer line. Share your project requirements and we’ll confirm the right configuration, spare parts plan, and service scope.

Standard Warranty

Typically 12 months for major non-wear components (final terms per contract and model).

Remote Technical Support

Fast troubleshooting guidance via video calls, manuals, and parameter checklists.

Spare Parts Plan

Recommended wear parts and critical spares to reduce downtime and keep output stable.

Installation & Training

Guidance for commissioning, operator training, and maintenance routines for long-term reliability.

Need warranty details for your material and output target? Send an inquiry.

Technical Support & FAQ

What is the warranty on this recycling machine?

We offer a comprehensive one-year limited warranty on all our recycling machines, covering key components and manufacturing defects. Extended service plans are also available.

How does this system minimize IV (Intrinsic Viscosity) loss?

Our single-screw design uses a specialized low-shear screw geometry and precise temperature control to minimize polymer degradation. Combined with efficient vacuum degassing, we typically keep IV drop within 0.03–0.05 dL/g, depending on input quality.

What is the maximum moisture content the flakes can have?

For optimal results, we recommend drying flakes to under 1% moisture before extrusion. However, our integrated vacuum degassing system can handle minor moisture fluctuations. For higher moisture levels, we can integrate an optional pre-drying crystallizer.

How often does the screen changer need servicing?

The hydraulic screen changer allows for non-stop operation. Changing screens takes less than 2 seconds and does not interrupt production. Frequency depends on contamination levels, but the dual-position design allows for continuous running during changes.

Is this suitable for bottle-to-bottle specific applications?

This single-screw line is ideal for bottle-to-fiber (staple fiber) and bottle-to-sheet applications. For food-grade bottle-to-bottle recycling requiring FDA compliance, we recommend our specialized SSP (Solid State Polycondensation) compatible twin-screw systems.

Project Request & Consultation

Our experts are ready to help you configure the perfect PET recycling machine for your specific needs. Fill out the form below for pricing and lead time.