Line-Level Plastic Recycling Solutions

We build complete, engineered recycling lines tailored to your feedstock and target output—covering size reduction, washing, separation, dewatering/drying, and downstream pelletizing. From process design to installation and commissioning, our solutions help you achieve stable throughput and consistent product quality.

End-to-End Line Engineering

From process design and line layout to commissioning, we deliver integrated solutions optimized for your material, contamination level, and capacity goals.

Modular, Scalable Architecture

Build your line from proven modules—shredding/granulation, washing, separation, drying, and pelletizing—then scale or upgrade as your business grows.

Automation & Process Control

Centralized PLC/HMI control with recipe management, alarms, and key parameter visibility helps reduce labor dependency and keep output consistent.

Stable Feeding & Material Handling

Conveying, buffering, and dosing are engineered for films, rigid regrind, and bulky parts—supporting smoother flow, fewer jams, and higher uptime.

Quality-Driven Washing & Separation

Targeted decontamination, rinsing, and separation improve cleanliness and stability—helping you hit tighter specs while lowering water and energy per ton.

Support Beyond Delivery

We support your line with installation, training, preventive maintenance, and spare parts—so you can run reliably and improve performance over time.

Explore Our Recycling Equipment Lineup

PET Bottle Recycling Washing System

Convert baled bottles into clean, high-value rPET flakes with efficient washing and separation.

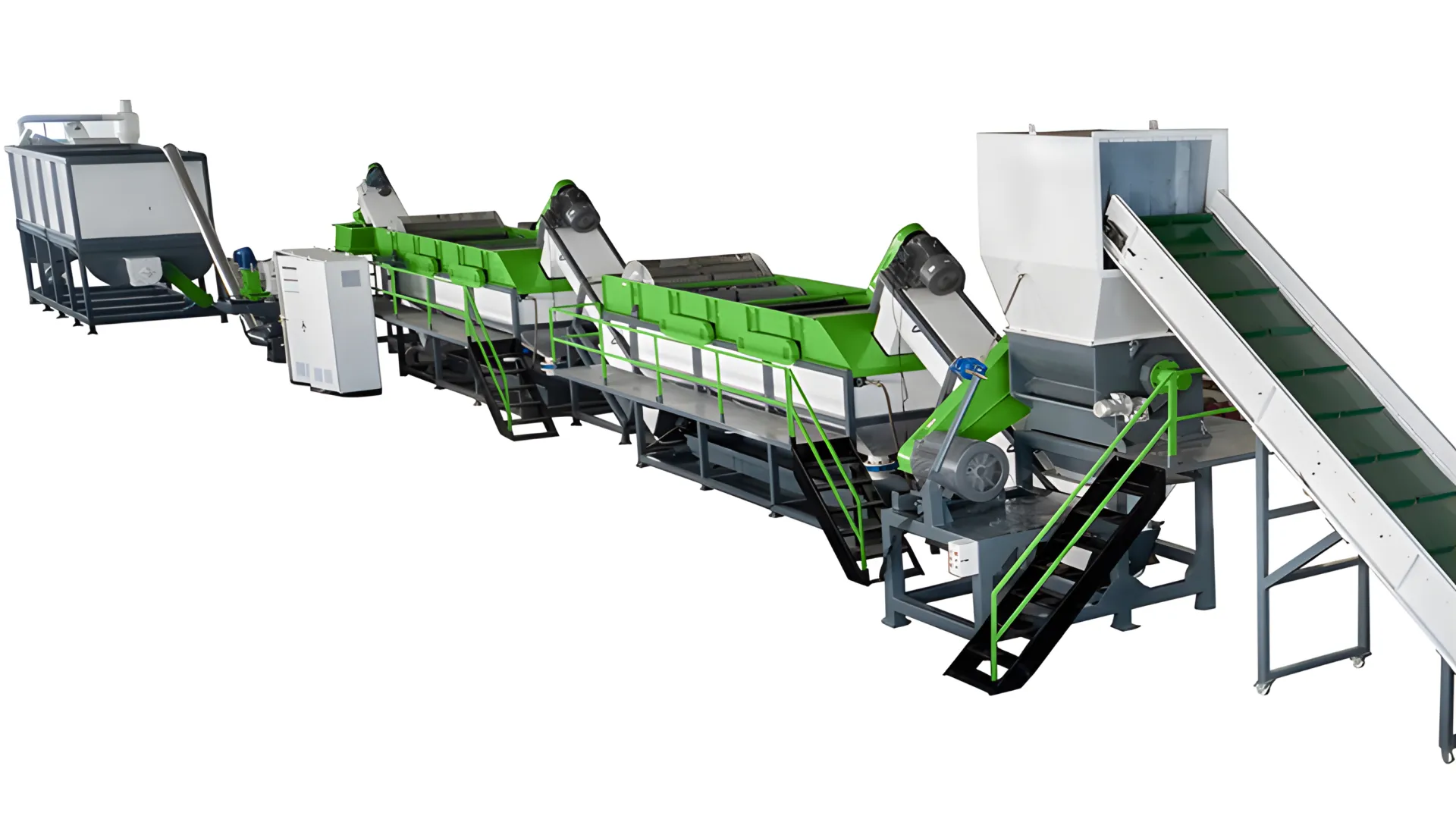

Rigid Plastic Recycling Washing Line (PP / HDPE / PVC)

Built for rigid regrind and industrial scrap—deliver cleaner flakes with reliable decontamination.

Plastic Film Shredding & Densifying Line (PP / PE / LDPE)

Integrated shredding and densifying helps stabilize film feeding and boosts downstream washing efficiency.

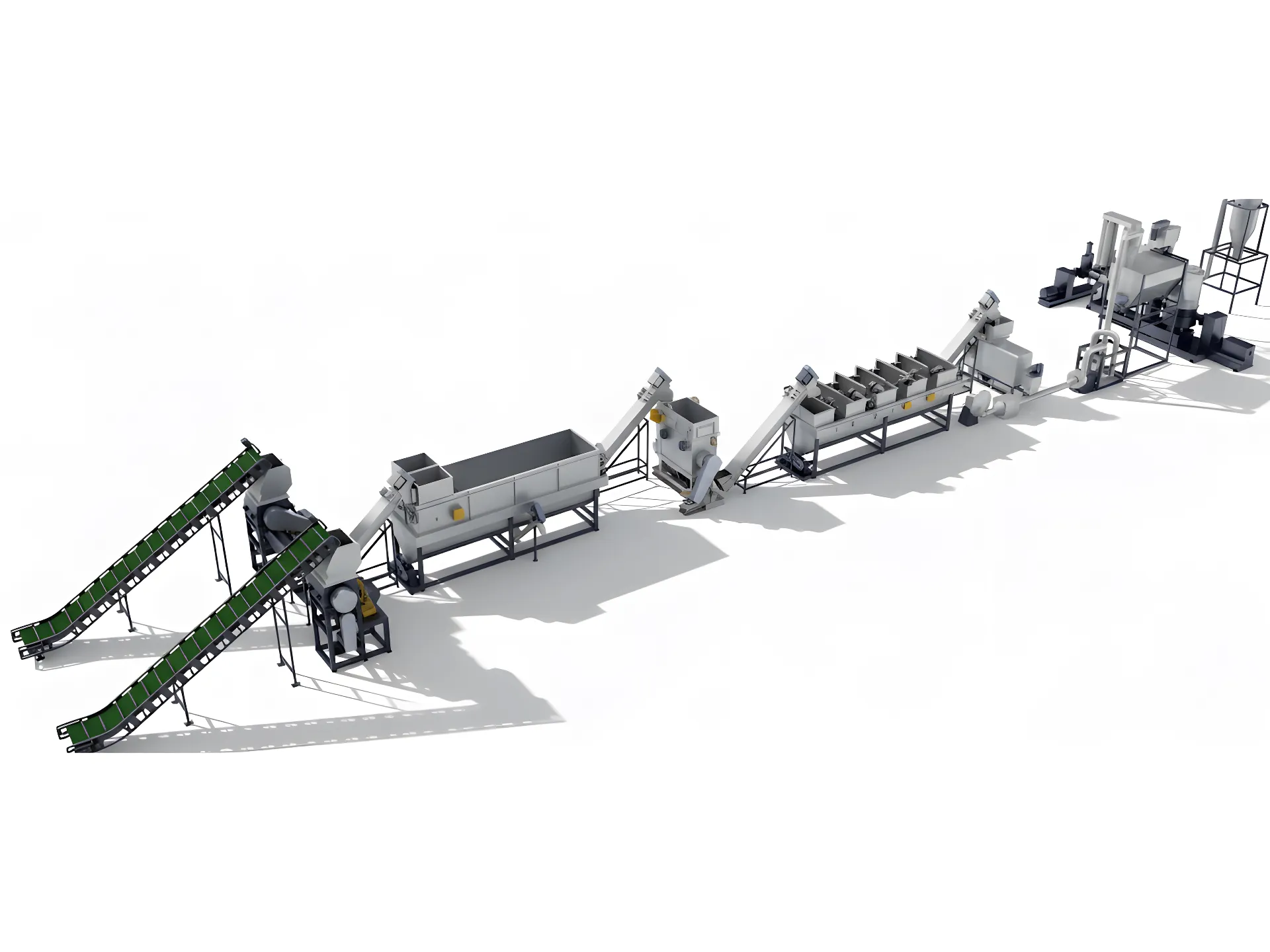

PP/PE Film Regrind Washing & Recycling Line

Dedicated washing and separation for film regrind—reduce contamination and improve output quality for reuse or pelletizing.

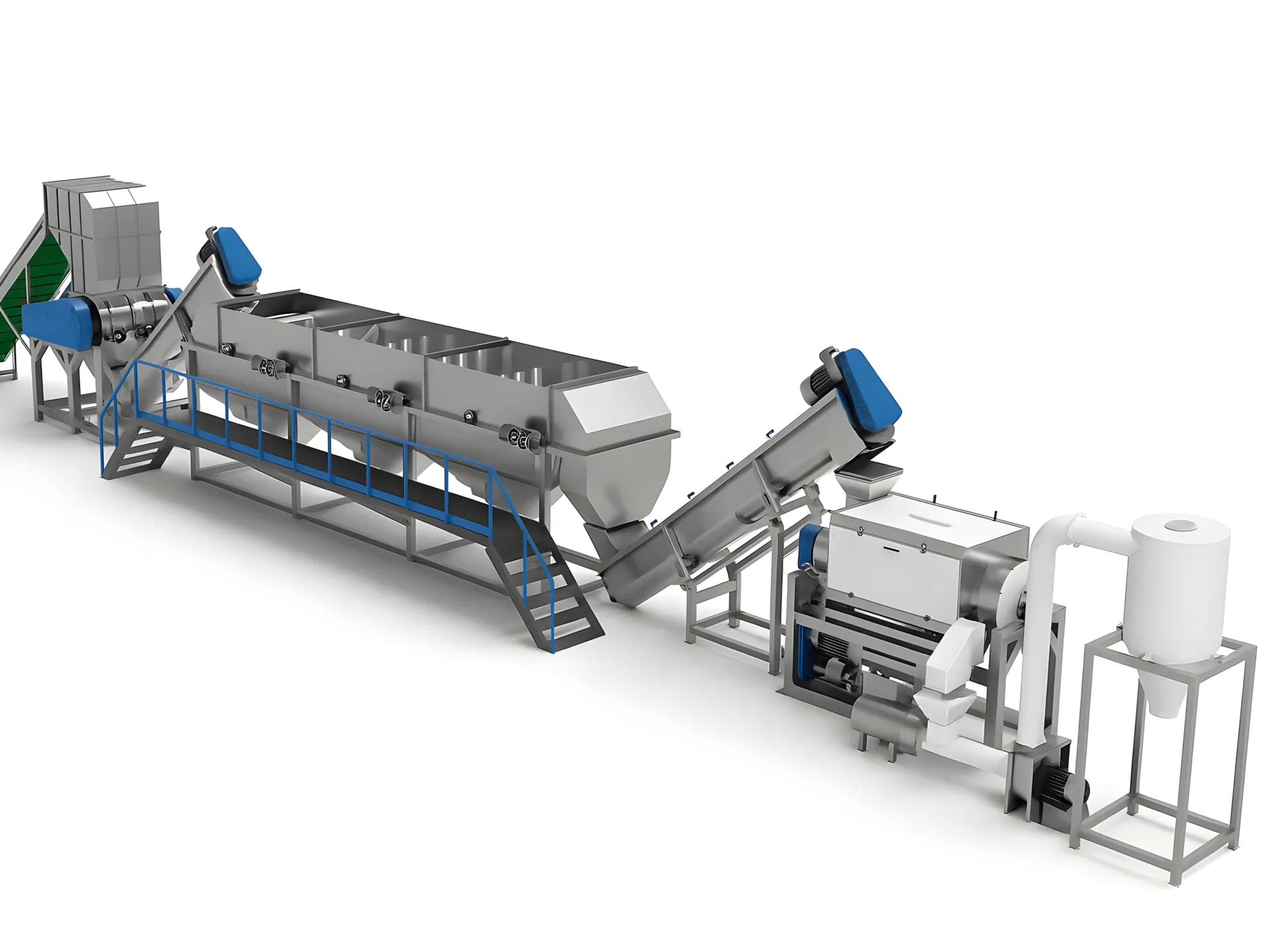

Fabric & Fiber Recycling Washing Line

Engineered for heavily contaminated films and fabrics—clean, dry flakes suitable for pelletizing.

HW49-B Hazardous Waste Container Washing Line

Automated washing line for hazardous waste containers—thorough cleaning, rinsing, and safe handling for reuse or compliant disposal.

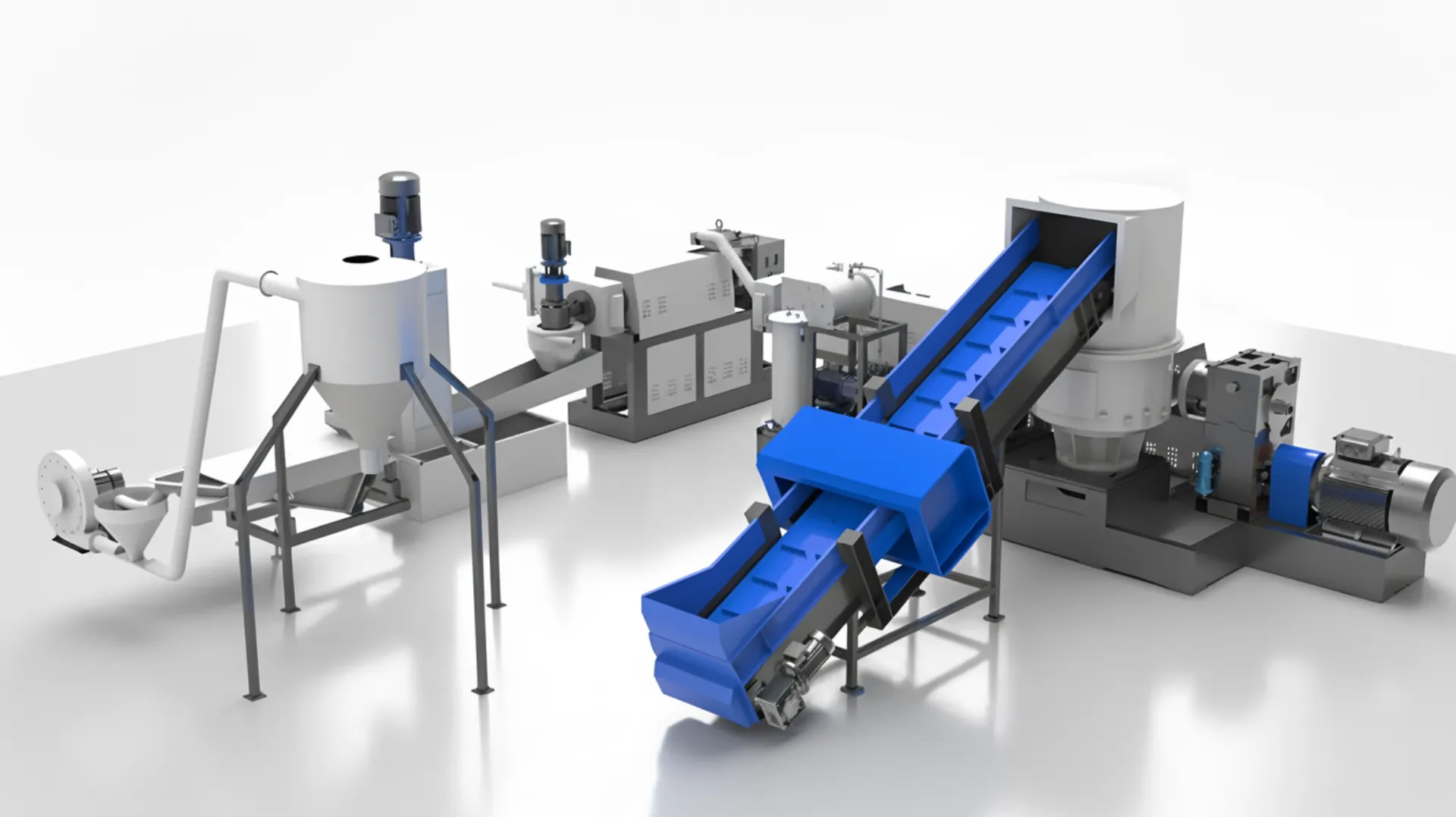

Plastic Pelletizing & Extrusion Systems

Convert clean flakes into high-quality pellets with stable extrusion, filtration, and cutter-compactor options tailored to your polymer.