High-Performance Shredder Replacement Blades

Engineered for maximum durability, precision cutting, and extended lifespan for your plastic recycling machines.

Why Choose Our Blades?

Manufactured with high-quality steel and stringent quality controls to ensure optimal performance.

Premium Steel Materials

Crafted from high-grade D2, SKD-11, and other alloy steels, heat-treated for superior hardness and wear resistance.

Precision Cutting

Engineered for accuracy, these blades provide clean cuts, reducing wear and tear on your recycling machines.

Cost-Efficient

Prolong the lifespan of your machines with our cost-effective replacement blades, ensuring consistent performance.

Easy Installation

Designed for hassle-free installation, minimizing downtime during blade replacement cycles.

Applications

Ideal for a wide range of plastic recycling scenarios.

Bottle Shredding

Perfect for processing various types of plastic bottles (PET, HDPE) with high throughput.

Film Shredding

Optimized geometry for handling soft plastic films (PE, PP) and reducing them to manageable sizes.

Pipe Shredding

Effective in shredding large diameter pipes and tough rigid plastics into smaller, recyclable chips.

Maintenance Best Practices

Follow these tips to maximize the lifespan and efficiency of your replacement blades.

Regular Inspections

Periodically heck the blades for signs of wear, chipping, or cracks. Early detection prevents costly damage to the machine.

Proper Cleaning

Keep the blades clean and free from residue buildup (such as melted plastic) that could affect cutting precision.

Timely Replacement

Replace blades as soon as they show significant dullness. Using dull blades increases energy consumption and machine stress.

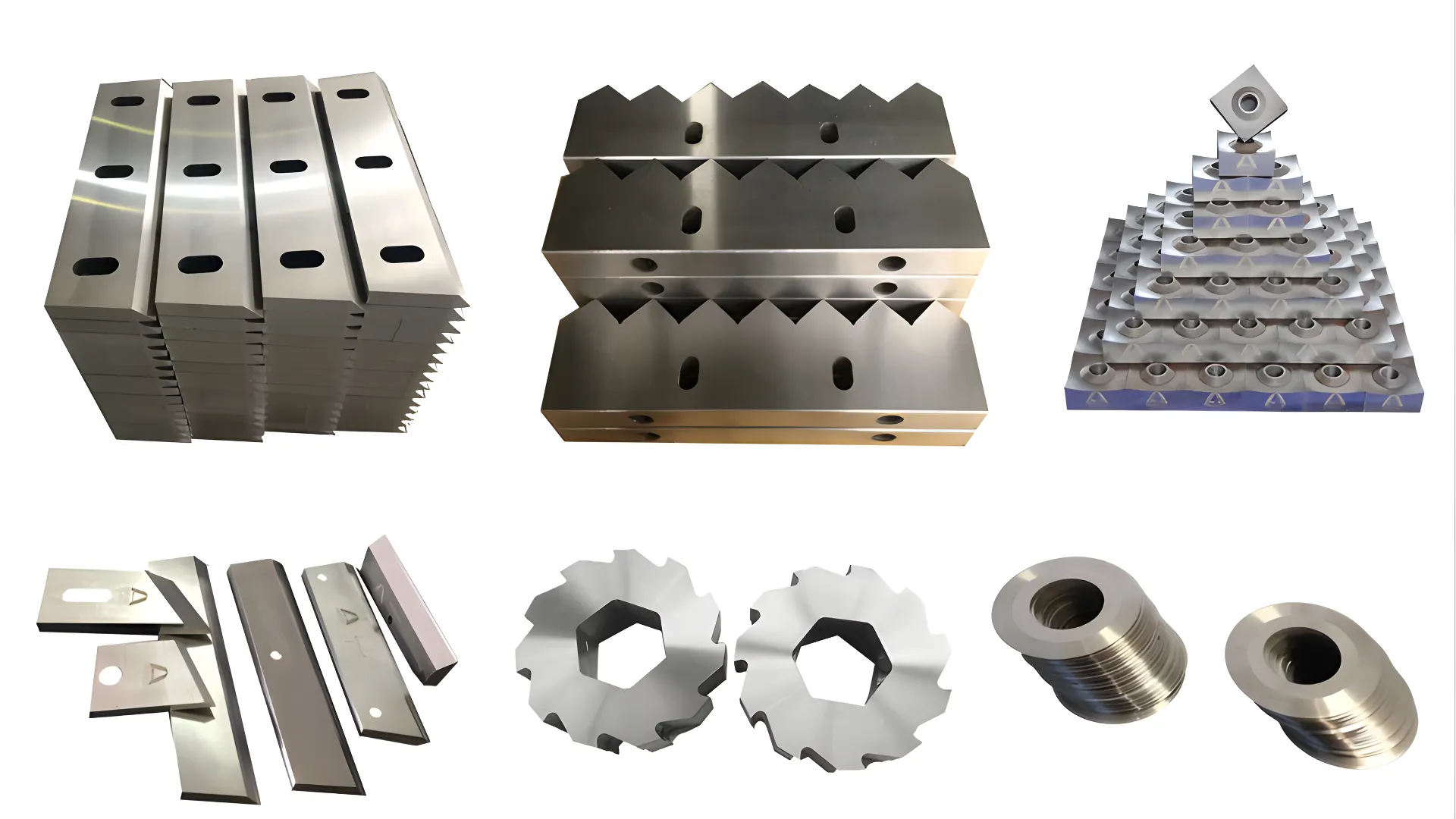

Product Gallery

Close-up views of our precision-engineered shredding components.

Frequently Asked Questions

What material are the blades made of?

Our blades are manufactured from high-grade alloy steel (such as D2, SKD-11, or customized grades) specifically heat-treated for maximum wear resistance and toughness required for plastic shredding.

Can you customize blades for my specific machine model?

Yes, we can manufacture blades based on your drawings or samples to fit various brands of shredders and crushers. Please contact us with your specifications.

How often should I sharpen or replace the blades?

This depends on the material being processed and daily usage volume. We recommend regular inspections (weekly) and sharpening when edges become rounded. Replacement is necessary when the blade has been sharpened beyond its minimum effective dimension.

Inquire Now

To get the latest prices and lead times, please send us a message using the form below.