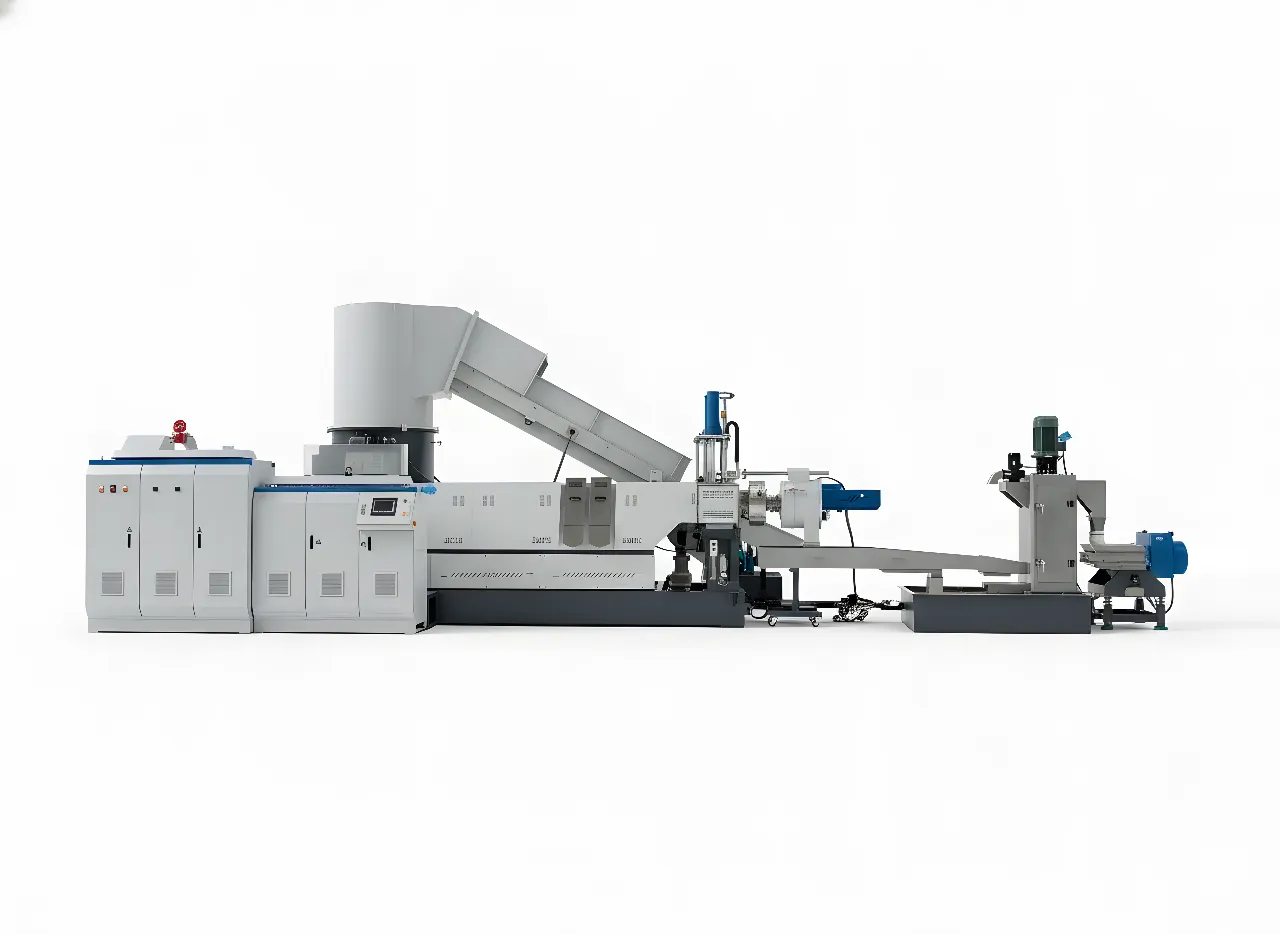

Single-Screw Plastic Pelletizing Machine

Engineered for stable, high-quality pellet production with precise temperature control and robust components. Available in single or double-stage configurations to fit your process.

Request a QuoteReliable Performance, Consistent Output

From gearbox to screw-and-barrel metallurgy, every detail is optimized to ensure uniform plasticization and smooth throughput. Ideal for converting plastic scraps into high‑density, reusable pellets with minimal downtime.

Key Features & Advantages

Stable Heat Control

Uniform barrel temperature for consistent melt quality and pellet shape.

Precision Gearbox

High-efficiency, low-noise transmission ensures steady screw rotation.

Durable Construction

Nitrided screw and barrel materials extend service life under heavy duty.

Flexible Setup

Single or double stage, strand or water‑ring pelletizing options.

How It Works

- Material Feeding: Pre‑crushed and cleaned plastic is fed into the extruder.

- Melting & Homogenizing: Screw conveys and plasticizes material with uniform heat control.

- Melt Filtration: Screen changer removes contaminants for clean, stable melt.

- Pelletizing: Choose water‑ring (melt) or strand cutting based on preference.

- Cooling & Drying: Efficient cooling and dewatering ensure pellet stability.

- Storage: Pellets conveyed to silo for packaging or reuse.

Main Technical Parameters

| Model | Screw Diameter | L/D | Driving Motor | Output |

|---|---|---|---|---|

| SJ-100 | ⌀100mm | 20/32 | 45–55 kW | 100–200 kg/h |

| SJ-120 | ⌀120mm | 20/32 | 55–75 kW | 100–200 kg/h |

| SJ-150 | ⌀150mm | 20/32 | 75–90 kW | 200–300 kg/h |

| SJ-180 | ⌀180mm | 20/32 | 90–132 kW | 200–400 kg/h |

| SJ-200 | ⌀200mm | 20/32 | 160–280 kW | 600–800 kg/h |

*Note: Specifications are subject to change. Contact us for a customized configuration.

Machine Showcase

Watch It in Action

See the pelletizing process and machine performance in a quick walkthrough.

Warranty & Installation

1-Year Limited Warranty

All of our recycling systems include a comprehensive one-year limited warranty.

Expert Support & Customization

We provide full customization, installation guidance, and after-sales support to ensure your line meets your exact needs.

Frequently Asked Questions

What types of plastic can this pelletizing line process?

Common applications include PP/PE films and rigid regrind, HDPE/LDPE, and other thermoplastics. The recommended configuration depends on contamination level, moisture, and your target pellet quality—share your material details for a matched setup.

What is the difference between single-stage and double-stage pelletizing?

Single-stage systems are efficient for relatively clean and stable input. Double-stage systems add a second filtration/extrusion step to improve melt stability and pellet consistency—often preferred for higher contamination or mixed materials.

Water-ring or strand pelletizing: which should I choose?

Water-ring pelletizing is compact and well-suited for many polyolefins with stable melt flow. Strand pelletizing is a robust choice when you prefer a simpler cutting approach or when material characteristics favor strand cooling and cutting.

How is contamination handled during extrusion?

A screen changer filters the melt to remove fine impurities. For more challenging input, we can add upstream pre-washing/drying and choose an appropriate filtration setup to protect the screw and improve pellet appearance.

What warranty and after-sales support do you provide?

All our machines come with a 1-year limited warranty. We also provide remote commissioning guidance, spare parts support, and maintenance recommendations to keep your line running smoothly.

Start Your Sustainable Production Today

All our machines come with a 1-year limited warranty. To get the latest prices and lead times, send us a message using the form below.