Effortless Metal Separation. Cleaner Material Flow.

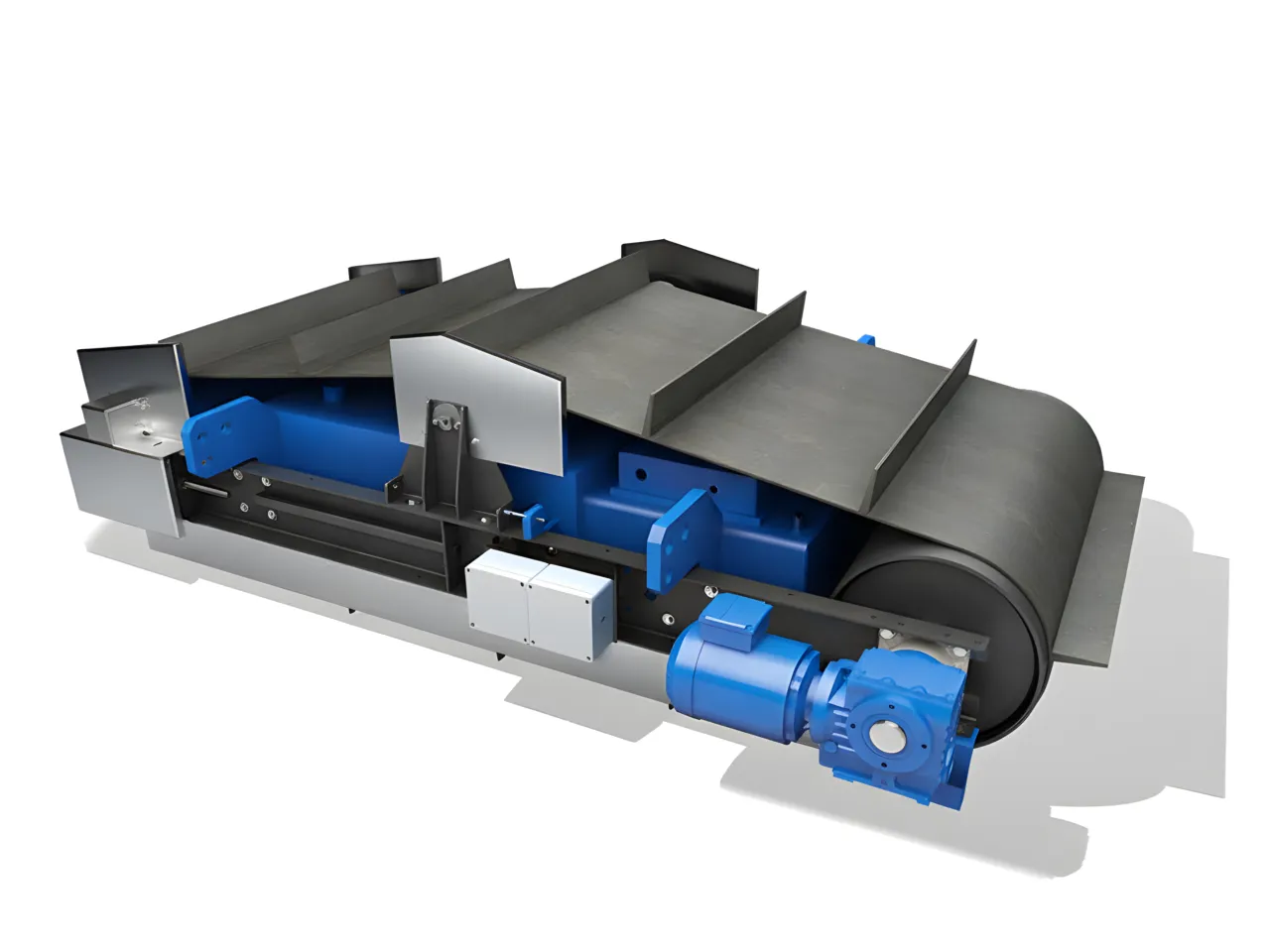

Introducing the Suspended Self-Discharging Magnetic Separator – your robust solution for automatically removing ferrous contaminants.

Streamline your processing line, protect valuable downstream equipment, and ensure product purity. Our separator integrates seamlessly above your existing conveyor, working tirelessly so you don’t have to.

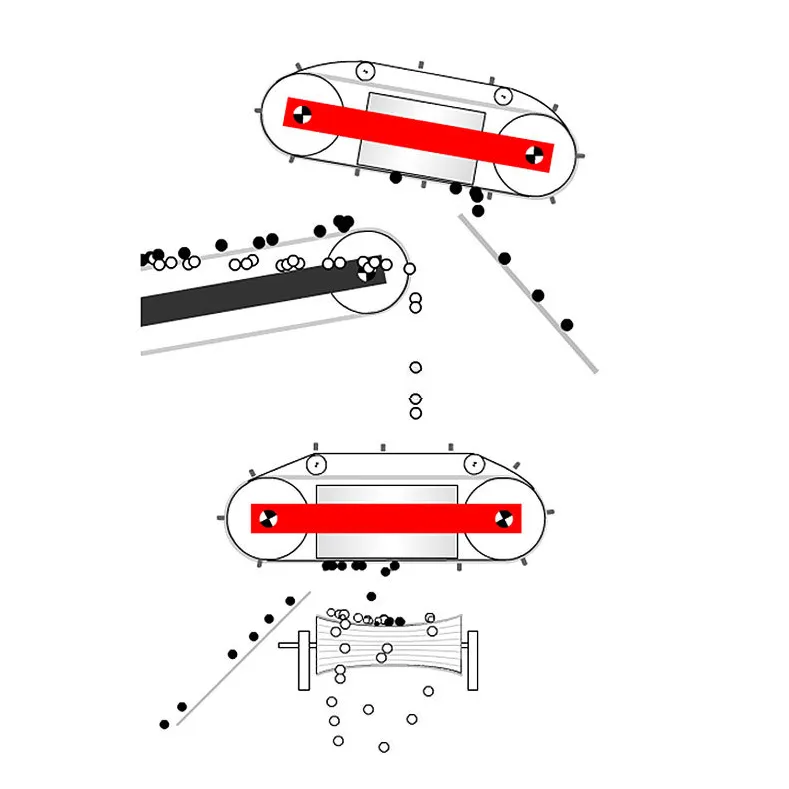

Powerful Magnetic Performance

Equipped with a high-intensity magnetic core featuring a strategic blend of Neodymium Iron Boron and Ferrite, it captures even challenging ferrous metals effectively from deep material burdens.

Automated Self-Cleaning

Maximize uptime. The integrated cleated belt automatically discharges captured metal away from the main flow, ensuring continuous operation with minimal maintenance.

Designed for Your Line

Flexible integration is key. This unit is engineered for:

- Conveyor Belts up to 800mm wide.

- Standard Suspension Height of 250mm (Adjustable).

- Material Burden Depths up to 300mm.

See it in Action

Watch how easily our separator integrates and operates to purify your material stream.

Built Tough

Constructed with durability in mind using robust Q235 steel and options for SU304 stainless steel components, ensuring longevity in demanding industrial environments.

Tech Specs at a Glance

| Belt Width Compatibility | Up to 800mm |

| Recommended Suspension Height | 250mm (Adjustable) |

| Max Material Thickness | 300mm |

| Magnetic Core Dimensions | 800mm x 600mm x 330mm |

| Magnetic Core Material | Neodymium Iron Boron + Ferrite Hybrid |

| Drive Motor Power | 3 KW |

| Frame & Shell Material | Q235 Steel (SU304 Stainless Steel options available) |

| Discharge Belt | Heavy-duty 10mm thick rubber belt with integrated scrapers |

Ready to Improve Your Purity?

Let’s discuss how this separator can fit into your specific application.