Unlock Efficiency in Plastic Recycling

Introducing the Vertical Debaler Machine: The automated solution to effortlessly break down compacted plastic bales and supercharge your recycling line.

Why Choose Our Vertical Debaler?

⚡

Unmatched Efficiency

Automates the debaling process, drastically reducing manual labor and preparation time.

📈

Boosted Throughput

Handles multiple bales simultaneously for continuous, high-volume processing.

💲

Significant Cost Savings

Minimizes operational expenses by lowering labor requirements and streamlining your workflow.

From Bale to Bottle in 4 Simple Steps

Load Bales

Use a forklift to place up to five bales onto the feeding conveyor.

Cut Straps

Quickly and safely cut the wires or straps securing each bale.

Automated Debaling

Dual counter-rotating rotors break apart compacted plastics with precision.

Continuous Output

Loosened materials flow onto the next conveyor, ready for recycling.

Engineered for Performance

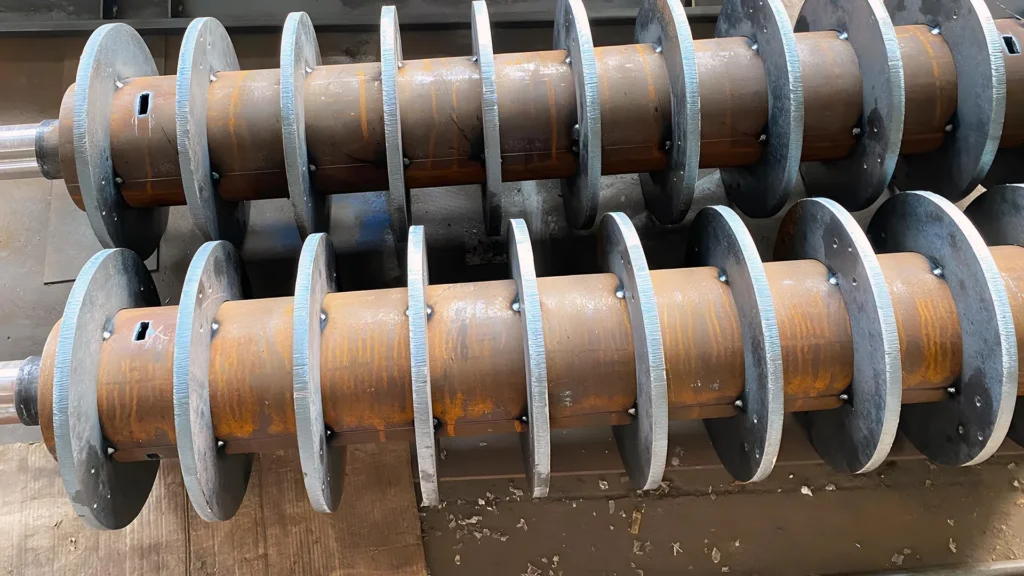

Dual Counter-Rotating Rotors

The heart of the machine, designed for maximum breaking force and efficiency.

Technical Specifications

| Feature | Specification |

| Main Motor Power | 7.5 kW x 2 (Total 15 kW) |

| Feeder Dimension | 1550mm x 1850mm |

| Applicable Materials | Compacted HDPE, PET bottles, and other rigid plastics |

| Certification | CE Certified |

| Customization | Higher power and larger models available upon request |

Versatile Applications & High-Quality Output

Get a Customized Solution & Quote

Ready to revolutionize your recycling operations? Fill out the form below, and our experts will contact you to discuss your specific needs.

Frequently Asked Questions

What is the primary function of the Vertical Debaler Machine?

The primary function is to automatically break apart compacted bales of rigid plastics like PET and HDPE bottles, preparing them for the next stage of the recycling process, such as sorting, washing, or shredding.

Can this machine handle plastic film bales?

No, this machine is specifically designed for rigid plastics. Plastic film can wrap around the rotors and cause damage. For plastic film bales, we recommend a specialized film shredder or bale breaker.

What is the throughput capacity?

The throughput depends on the model and the density of the bales. Our standard model can process several tons per hour. We can provide exact figures based on your specific material and bale size.

How much manual labor is required?

Manual labor is minimal. An operator is needed to load the bales with a forklift and to cut the bale wires/straps before they enter the machine. The debaling process itself is fully automated.