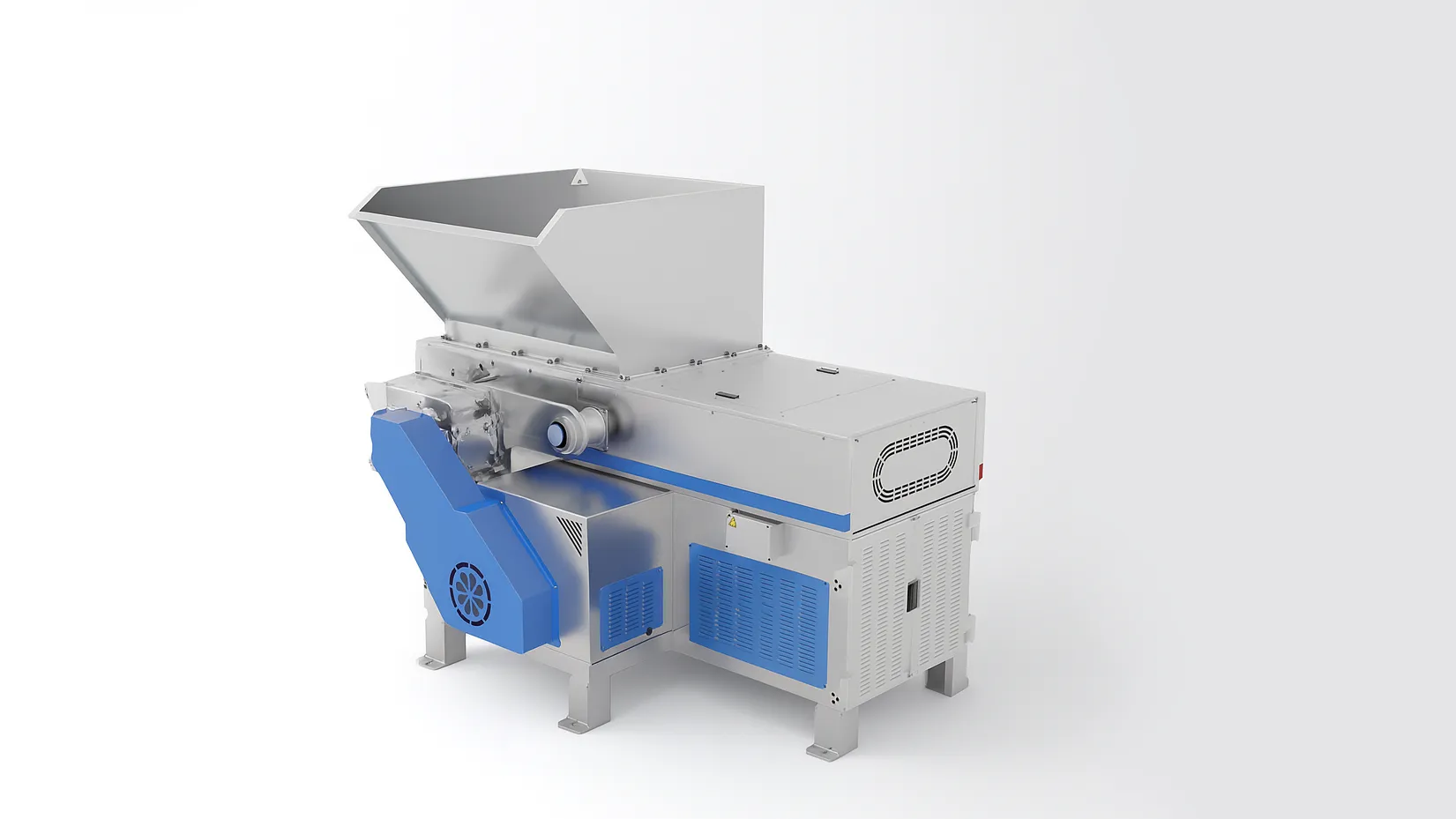

High-Torque Wood & Pallet Shredder

Transform bulky wood waste, pallets, and offcuts into valuable, uniform chips for biomass fuel or easy disposal. Slash your transport and handling costs.

Turn Wood Waste Into a Valuable Resource

Our shredder is a robust, customizable solution designed to maximize the value of your wood scrap while minimizing operational costs.

Slash Disposal Costs

Drastically reduce the volume of your wood waste to cut down on expensive transport and disposal fees.

Create Valuable Biomass

Produce consistent, homogeneous granulate perfect for wood chip furnaces, biogas plants, or for making profitable wood briquettes.

Versatile & Customizable

Handles all types of wood waste, from pallets to MDF. We can customize the machine to match your specific throughput needs.

Built for Durability

Engineered with high-quality materials and advanced manufacturing to withstand the rigors of industrial use and ensure longevity.

Solve Your Wood Waste Challenges

Piles of scrap wood and used pallets are a logistical headache and an untapped resource. Our shredder provides a direct and profitable solution.

Problem: Bulky, Costly Waste

Large stacks of used pallets, offcuts, and timber waste consume valuable space and are expensive to transport and dispose of.

Solution: Drastic Volume Reduction

Our shredder transforms bulky waste into a compact, uniform, and easy-to-handle resource, freeing up space and cutting transport costs.

Problem: Lost Revenue Stream

Paying to have wood waste hauled away is a direct loss. This material has significant potential value as an energy source or raw material.

The Single-Shaft Shredding Process

A powerful and methodical process designed to break down all types of wood waste with automated precision.

1. Loading the Hopper

Wood waste, including whole pallets and large offcuts, is loaded directly into the shredder's large feeding hopper.

2. Hydraulic Ram Feed

A hydraulic ram automatically pushes the wood with controlled pressure into the high-torque cutting rotor.

3. High-Torque Shearing

The slow-speed, high-torque rotor equipped with hardened steel knives cuts and tears the wood against a fixed counter-knife.

4. Sizing and Discharge

A heavy-duty screen with a specific hole size (12-80mm) is positioned below the rotor to ensure a uniform final chip size before discharge.

Watch It In Action

Versatile Output for Diverse Industries

The uniform wood chips produced by our shredder are a valuable commodity for a wide range of industrial and commercial uses.

Biomass Energy Production

The ideal feedstock for biomass co-generation plants, biogas facilities, and industrial or in-house wood chip furnaces.

Wood Product Manufacturing

A primary material for producing high-quality wood briquettes, particleboard, and other composite wood products.

Waste Management & Recycling

Essential for sawmills, furniture factories, and logistics centers to efficiently process waste and reduce disposal volume.

Technical Specifications

| Model | Shaft Diameter (mm) | Moving Knives | Max Capacity (kg/h) | Motor Power (KW) | Chamber Size (mm) |

|---|---|---|---|---|---|

| ERM-600 | 320 x 45 | 12 | 800 | 18.5 x 2 | 600 x 780 |

| ERM-800 | 320 x 45 | 16 | 1000 | 22 x 2 | 800 x 780 |

| ERM-1000 | 400 x 50 | 20 | 2000 | 45 x 2 | 1000 x 880 |

| ERM-1200 | 400 x 50 | 24 | 3000 | 55 x 2 | 1200 x 880 |

| ERM-1600 | 500 x 65 | 24 | 5000 | 75 x 2 | 1600 x 960 |

| ERM-2000 | 600 x 77 | 28 | 8000 | 90 x 2 | 2000 x 1100 |

Frequently Asked Questions

What types of wood waste can this shredder handle?

Our shredder is highly versatile and can process all mixed woodworking waste, including hard and soft woods, pallets, crates, solid timber, offcuts, veneers, particleboard, and MDF boards.

How is the final size of the wood chips controlled?

The final granulate size is determined by a perforated screen located beneath the cutting rotor. We offer a range of screen sizes with holes from 12mm to 80mm, allowing you to produce the exact chip size required for your specific application.

Can the shredder be customized for my facility?

Yes. We understand that every operation is unique. Our shredders are customizable with various working widths, rotor diameters, and drive capacities to perfectly match your material type and required throughput.

Turn Your Wood Waste Into a Valuable Resource

Stop letting wood waste management slow down your business. Contact us today to discover how our shredder can streamline your operations and improve your bottom line.