A Comprehensive Guide to Selecting the Right PVC Recycling Equipment

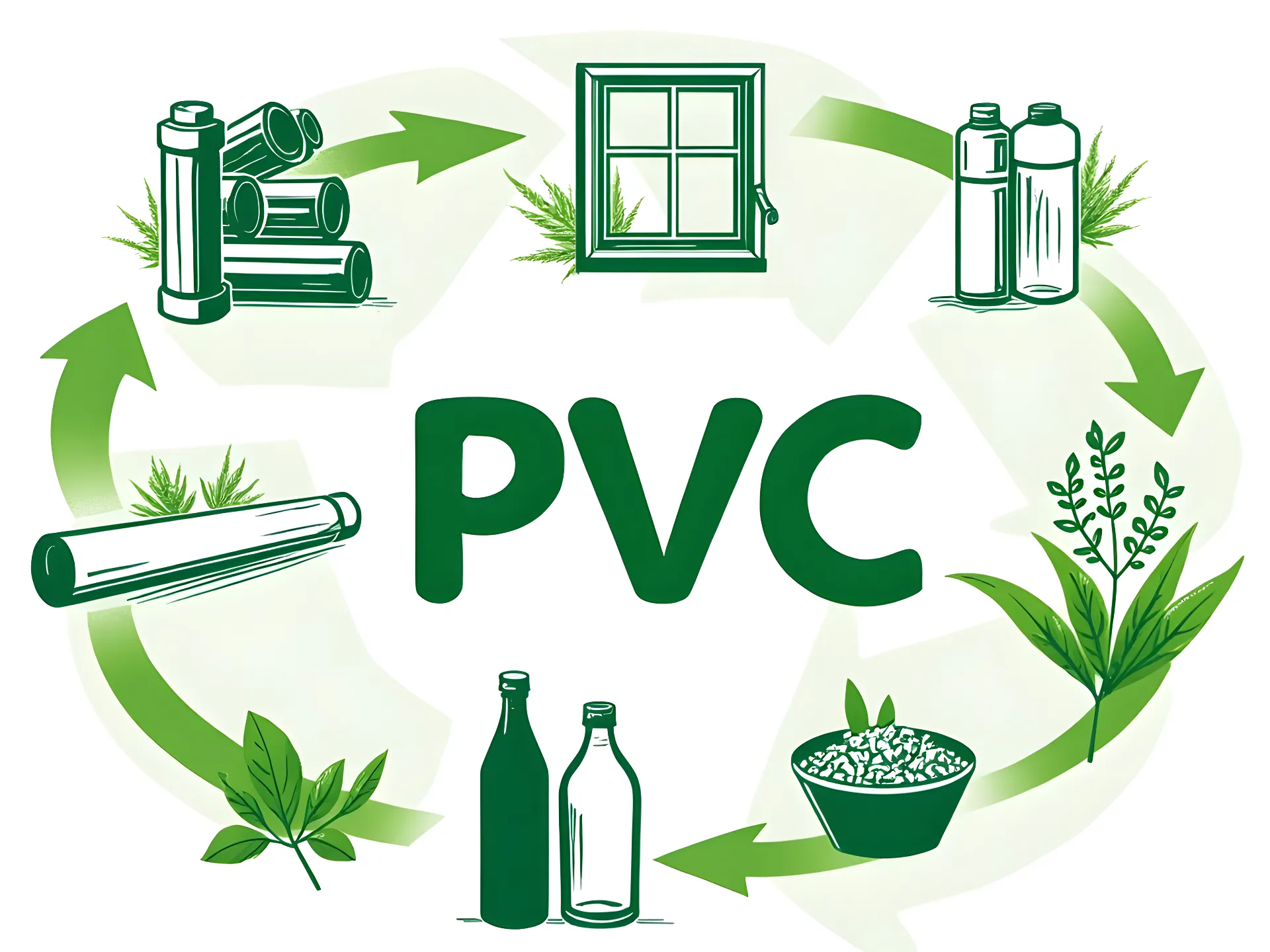

Choosing the right PVC recycling machine is a critical decision for any business aiming to process this versatile and widely used plastic. Polyvinyl chloride (PVC) is found in everything from durable construction pipes and window frames to flexible packaging films and medical tubing. However, recycling PVC presents unique challenges compared to other plastics like PET or HDPE. Success requires more than just a single machine; it demands an integrated system specifically designed to handle the distinct properties of PVC.

This guide provides a detailed look at the PVC recycling process, the essential equipment for each stage, and the key criteria to consider when investing in a complete recycling line.

Why PVC Recycling Requires Specialized Equipment

Unlike simpler polymers, PVC has a complex chemical structure that includes chlorine. It also comes in two primary forms with vastly different properties:

- Rigid PVC (uPVC): Unplasticized, strong, and durable. Commonly used for pipes, window profiles, and siding. It is dense and sinks in water.

- Flexible PVC (pPVC): Contains plasticizers to make it soft and pliable. Used for electrical cable insulation, flooring, and inflatable structures. Its properties can vary widely based on the additives used.

This diversity means a one-size-fits-all approach to recycling will fail. An effective PVC recycling machine or system must be able to manage potential issues like the release of hydrochloric acid at high temperatures and separate a wide range of contaminants.

The PVC Recycling Process: A Step-by-Step Equipment Breakdown

A successful PVC recycling operation is a multi-stage process. Each stage requires specific machinery working in harmony to transform waste into high-purity, reusable PVC flakes or pellets.

Step 1: Size Reduction – Shredders and Granulators

The process begins with reducing the size of bulky PVC waste. A low-speed, high-torque shredder is ideal for the initial breakdown of large, tough items like pipes and window profiles. The rough shreds are then fed into a granulator (or crusher), which uses high-speed rotating blades to chop the material into uniform flakes, typically less than 12mm in size.

Step 2: Washing and Contaminant Removal

This is the most critical stage for producing high-quality recycled PVC. A robust washing line is essential. The key components include:

- Friction Washer: Uses high-speed paddles to scrub the PVC flakes, removing dirt, labels, and other surface contaminants.

- Hot Washer: Soaking the flakes in hot water with a cleaning agent is crucial for removing stubborn glues and residues.

- Sink-Float Separation Tank: This tank uses water density to separate materials. Rigid PVC, being denser than water, sinks to the bottom, while other plastics like PP and PE, as well as label fragments, float to the top and are skimmed off.

Step 3: Drying

Before the clean PVC flakes can be reprocessed, they must be thoroughly dried. Any residual moisture can cause imperfections in the final product. The drying process typically involves a two-stage approach: a mechanical dewatering machine to spin off the bulk of the water, followed by a thermal drying system that uses hot air to achieve a final moisture content of less than 1%.

Step 4: Reprocessing – Pelletizing

The clean, dry PVC flakes are then fed into a pelletizer (or extruder). This machine melts the flakes and pushes the molten plastic through a die to form spaghetti-like strands, which are then cut into uniform pellets. PVC extruders require special features like corrosion-resistant screws and barrels, as well as vents to safely remove any trapped gases (degassing).

Engineered for Purity: Our Rigid Plastic Washing Lines

Energycle’s complete washing lines are designed to handle the specific challenges of materials like PVC, PP, and HDPE. Achieve high-purity output and maximize the value of your recycled materials.

Explore the PVC Washing LineKey Selection Criteria for Your PVC Recycling Equipment

When investing in a PVC recycling line, consider these critical factors to ensure you get a system that meets your needs and delivers a strong return on investment.

- Material Specificity: Can the system effectively process your specific feedstock (e.g., rigid pipe vs. flexible film)?

- Throughput Capacity: What is the system’s processing capacity in kilograms or tons per hour? Plan for future growth.

- Purity of Output: What is the guaranteed purity level of the final PVC flakes? Look for systems that promise low contamination rates.

- Build Quality: Are components that contact PVC, especially in the extruder, made from corrosion-resistant materials?

- Energy and Water Consumption: Request data on the system’s efficiency to forecast operational costs accurately.

- Automation Level: A highly automated system with a central PLC control panel reduces labor needs and improves process consistency.

- Footprint and Layout: Ensure the complete line can be configured to fit within your available facility space.

- Manufacturer Support: Does the supplier offer installation, training, and readily available spare parts?

Ultimately, selecting the right PVC recycling machine means choosing a complete, integrated system. Each component, from the initial shredder to the final pelletizer, plays a vital role in achieving the desired quality and efficiency. As industry bodies like The Vinyl Institute continue to promote advanced recycling, investing in purpose-built equipment is the key to a profitable and sustainable operation. To discover more about recycling solutions, visit the Energycle Machine homepage.