Non-Ferrous Metal Separation

Advanced Eddy Current Separator for Recycling Lines

Recover high-value aluminum, brass, bronze, and copper in a single pass. Our eddy current separator (ECS) maximizes non-ferrous recovery, boosts PET flake purity, and increases revenue from mixed recycling streams.

Why Recycling Plants Choose Our ECS

From PET bottle flake producers to MSW sorting facilities, operators rely on our eddy current separator to capture more non-ferrous metal and unlock higher-value recycled outputs.

High Recovery Rates

Optimized pole design and high-frequency rotor generate stronger eddy currents for precise ejection of non-ferrous metals.

Wide Process Window

Adjustable rotor speed, splitter plates, and belt controls let you adapt to changing material mixes within minutes.

Handles Tough Streams

Processes PET bottle flakes, aluminum packaging, electronic scrap, and automotive shredder residue with stable throughput.

Low Maintenance Design

Durable wear liners, sealed bearings, and quick-access panels simplify belt replacement and rotor inspections.

How the Advanced Eddy Current Separator Works

A high-speed alternating magnetic field induces eddy currents in non-ferrous metals, pushing them into a separate trajectory from the rest of the material flow.

Material Feed

Mixed material with non-ferrous content is evenly metered onto the conveyor belt for a controlled burden depth.

Magnetic Rotor

A rare-earth magnet rotor spins up to 4500 rpm inside the head pulley, creating rapidly changing magnetic fields.

Eddy Current Repulsion

Non-ferrous particles experience induced currents and are propelled forward, clearing the adjustable splitter.

Clean Separation

Recovered metals fall into dedicated collection bins while plastics, glass, or wood drop on a separate trajectory.

Integration & Use Cases

Position the ECS near the end of your sorting line to polish material streams and lift total recovery rates.

PET Bottle Recycling

Remove stray aluminum caps, rings, and foil from flake to protect downstream extruders. Pair with the PET Bottle Recycling System.

Municipal MRFs

Boost beverage can capture and reduce contamination in paper or plastic fractions, even with fluctuating inbound tonnage.

Electronics & ASR

Recover high-value copper and aluminum from e-waste and automotive shredder residue before further refining.

Performance Highlights

Engineered to keep your line running smoothly with predictable separation efficiency.

Rare-Earth Rotor

Neodymium magnets and high pole frequency deliver strong repulsive forces across lightweight particles.

Fine Tuning Controls

Adjustable splitter blades, belt speed, and rotor frequency maintain recovery even as feed composition changes.

Safety Focused

Guarding, e-stops, and vibration monitoring meet safety standards while protecting operators and equipment.

Combine with Ferrous Separation

Install the ECS after ferrous removal to ensure both magnetic and non-ferrous metals are captured.

Suspension Magnetic Separator

Remove ferrous metals before the ECS so the eddy current field focuses on aluminum and copper.

High-Intensity Roller

Separate stainless steel and weakly magnetic metals that traditional ferrous magnets may miss.

Air Classification

Pair with a Zig-Zag Air Classifier to remove lightweight contaminants before non-ferrous recovery.

Technical Specifications

Standard configurations are shown below. We tailor rotor width, pole count, and splitter layouts to match your material stream and plant footprint.

| Parameter | Typical Range |

|---|---|

| Working Width | 650–1500 mm |

| Rotor Diameter | 380–500 mm (neodymium rotor) |

| Rotor Speed | 1500–4500 rpm (variable frequency drive) |

| Belt Speed | 1.5–3.2 m/s |

| Throughput | Up to 10 t/h (material dependent) |

| Drive Power | 11–37 kW main drive + 1.5–4 kW rotor motor |

| Splitter Adjustment | Manual or motorized positioning |

| Frame Option | Modular support frame with vibration isolation pads |

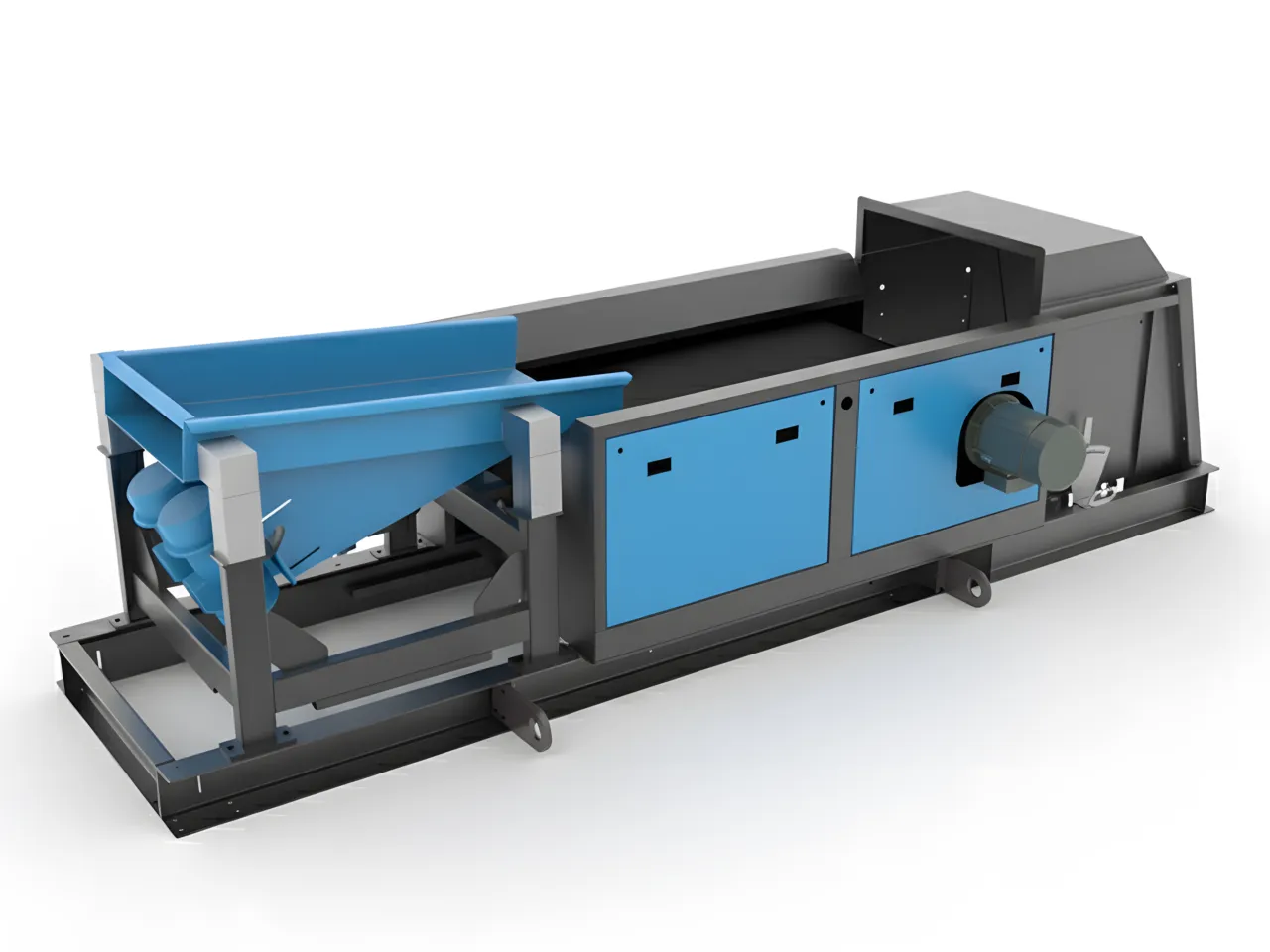

Machine Photos

See the ECS installed in PET recycling plants and mixed material sorting facilities.

Frequently Asked Questions

Which materials can the ECS recover?

It targets non-ferrous metals such as aluminum, brass, bronze, and copper. Lightweight metals like shredded aluminum UBCs and copper wire pieces eject cleanly, improving the purity of plastics, glass, and wood fractions.

Do I still need magnetic separation?

Yes. Install overband or drum magnets ahead of the ECS to remove ferrous metals. This prevents rotor damage and allows the eddy current field to focus on non-ferrous recovery.

How do I optimize separation performance?

Maintain consistent feed depth, tune rotor speed with the VFD, and adjust splitter angles based on particle size. Keeping the belt clean and replacing wear liners on schedule sustains efficiency.

Where should the ECS be placed in my line?

Position it after size reduction and screening so material is uniform. Most recycling plants install it after ferrous magnets and before optical sorters or final quality control.

Installation, Training & Support

Every eddy current separator includes on-site commissioning, operator training, and a 12-month warranty. Remote diagnostics and spare rotor assemblies are available for high-throughput facilities.

Ready to Improve Non-Ferrous Recovery?

Tell us about your material stream, target recovery rates, and available footprint. We’ll configure an ECS tailored to your recycling line.