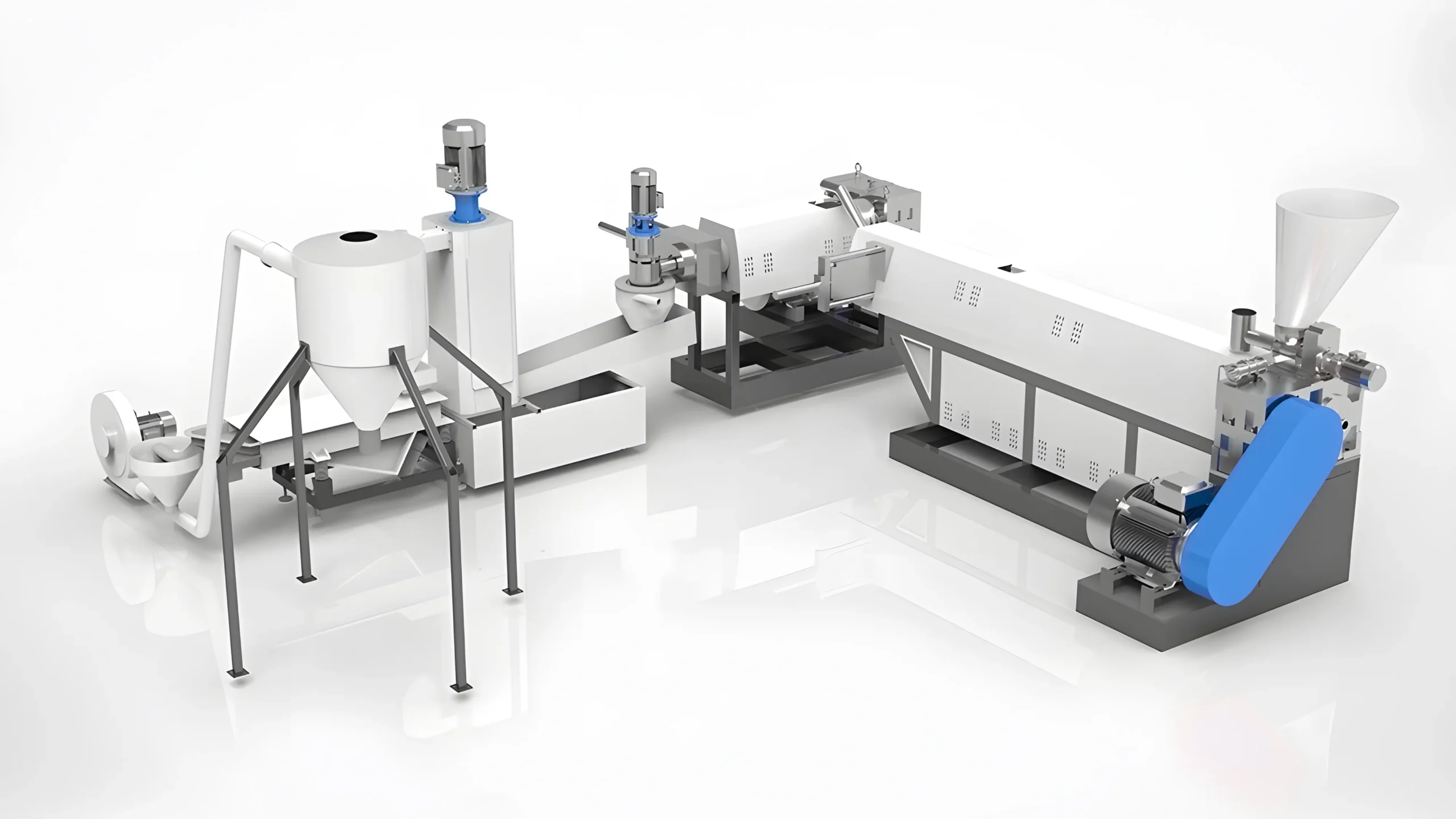

Your Cutting-Edge BOPP Film Recycling Granulating Line

Efficiently convert BOPP film scraps into reusable raw materials, maximizing output and minimizing waste. Get your high-performance granulating line today!

Get Custom Solutions & QuoteWhy Choose Our Granulating Lines?

Increased Output

20% higher output than previous models for maximizing recycling capacity.

Reduced Energy Consumption

Save up to 15% on energy costs with our energy-efficient design.

Automated Operation

Automated systems with minimal human intervention, requiring only two operators.

Superior Pellet Quality

Advanced extruders deliver high-quality, uniform, and moisture-free pellets.

Versatile Applications for Various BOPP Film Types

- Printed BOPP Film

- Heavily Printed BOPP Film

- Washed BOPP Film

- Metalized BOPP Film

- Film Rolls, Loose Film, and Bundled Film

Our Efficient 7-Step Recycling Process

- Material Feeding: BOPP film is fed via a belt conveyor.

- Compaction: The film is compacted for consistent feeding.

- Extrusion & Degassing: A special extruder melts material, and a double-zone vacuum degassing system removes moisture.

- Filtration: Advanced filtration systems ensure pure pellets.

- Pelletizing: A water-ring die-face cutting system shapes uniform pellets.

- Drying: Vibration drying removes residual moisture from the pellets.

- Storage: Dried pellets are transferred to silos via a pneumatic system for storage.

Technical Specifications

| Model | Screw Diameter | Output (kg/h) |

|---|---|---|

| EMGL85 | Φ85mm | 180~250 |

| EMGL100 | Φ100mm | 300~400 |

| EMGL130 | Φ130mm | 500~600 |

| EMGL160 | Φ160mm | 700~800 |

| EMGL180 | Φ180mm | 1000~1500 |

See It In Action

Product Gallery

Ready to Boost Your Recycling Efficiency?

Contact us today to explore tailored solutions for your BOPP film recycling needs and receive a personalized quote!

Frequently Asked Questions

What types of BOPP films can be recycled?

Our granulating lines can process a wide variety of BOPP films, including printed, heavily printed, post-industrial, washed, and metalized films. The system is versatile enough to handle film in rolls, loose scraps, or bundled forms.

How does the energy efficiency compare to other systems?

Our systems are engineered for high efficiency, reducing energy consumption by up to 15% compared to conventional models. This is achieved through an optimized screw design, advanced heating technology, and intelligent motor control.

What is the quality of the final pellets?

The final product is high-quality, uniform, and dense pellets that are almost 100% dry. The advanced double-zone vacuum degassing and filtration system ensures the removal of volatiles and contaminants, making the pellets ideal for direct reuse in production lines.