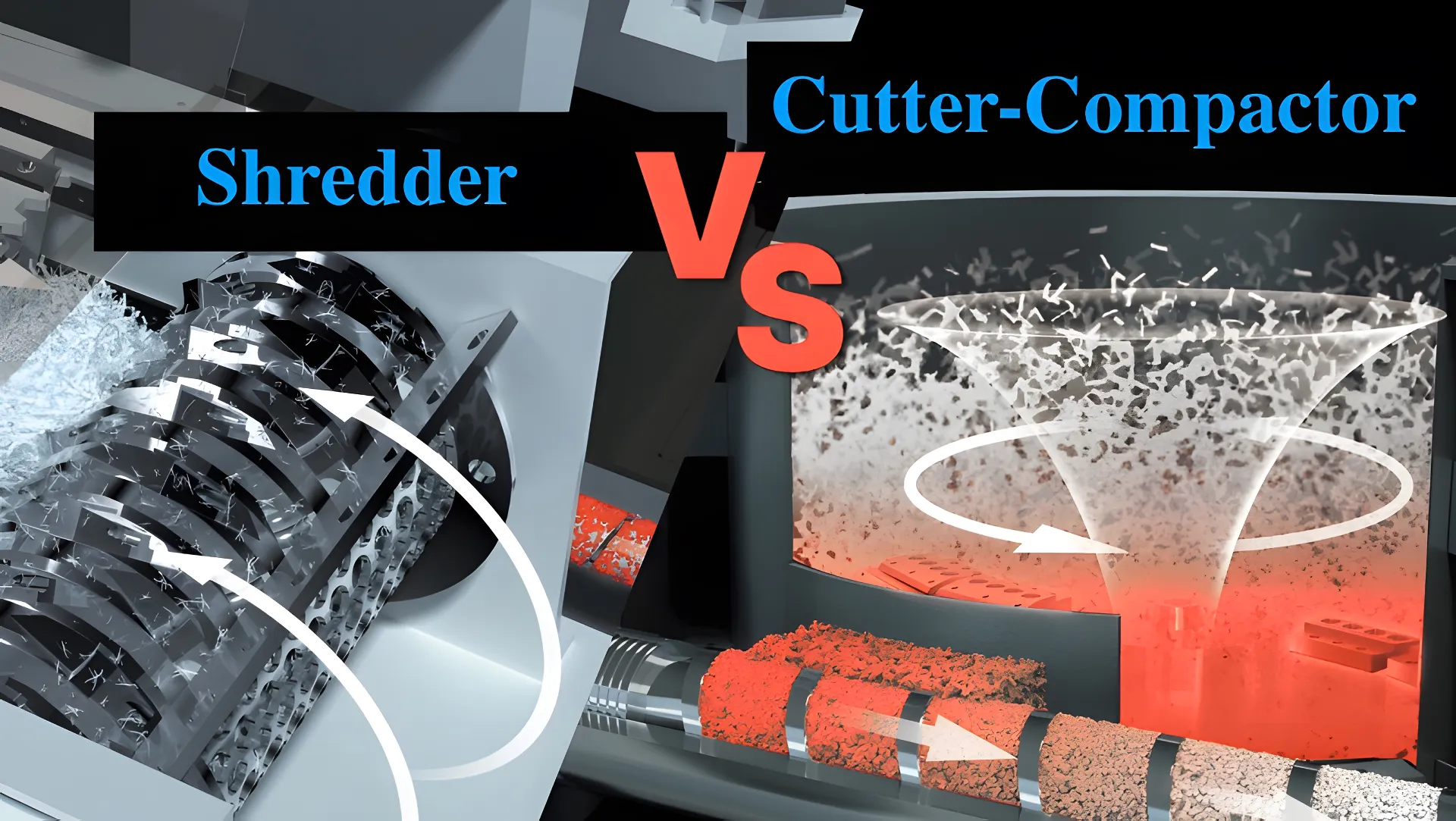

When designing a plastic recycling line, the primary bottleneck is often the feeding mechanism. Cutter-Compactor systems (integrated) and Shredder-fed systems (modular) solve this differently. This guide breaks down the operational workflows, maintenance demands, and troubleshooting protocols for each, helping plant managers select the right architecture for their floor.

Related equipment: PE/PP film shredder, extruder lumps shredder.

Workflow 1: The Cutter-Compactor (Integrated)

Ideal for: Post-Industrial Film (LDPE/LLDPE), BOPP, CPP, Woven Bags

How It Works

- Direct Feeding: Light, fluffy scrap is conveyed directly into the compactor pot.

- Densification: High-speed rotating knives cut and friction-heat the material, increasing bulk density from ~50 kg/m³ to ~300 kg/m³.

- Tangential Dosing: The densified, hot material is centrifugally force-fed into the extruder screw.

- Extrusion: The screw melts the pre-heated polymer with minimal shear, preserving material properties (IV drop is minimized).

Operational Advantages

- One-Step Process: Eliminates the need for a separate shredder, conveyor, and force feeder.

- Self-Regulating: If the extruder pressure rises, the compactor slows down automatically (on advanced PLCs), preventing overfeeding.

- Moisture Flash-Off: The friction heat evaporates surface moisture (up to 5%), acting as an efficient pre-dryer.

Troubleshooting

- “Material Bridging”: If the compactor gets too hot (>110°C for LDPE), the plastic melts into a “log” instead of crumbs. Solution: Increase cooling water flow to the pot or reduce blade speed.

- Blade Wear: Dull blades generate less heat but cut poorly. Sharpening is required every 40-80 hours for optimal performance.

Workflow 2: The Shredder-Fed Line (Modular)

Ideal for: Rigid Plastics (HDPE/PP), Purging Lumps, Contaminated Film

How It Works

- Size Reduction: Material is dumped into a large single-shaft shredder, reducing it to 40mm chips.

- Buffer Storage: Chips are conveyed to a silo or buffer hopper.

- Force Feeding: A side-feeder or crammer-feeder pushes the cold chips into the extruder.

- Shear Melting: The extruder screw typically does most of the work to melt the cold plastic, requiring a longer L/D ratio (typically 32:1 or higher).

Operational Advantages

- Contamination Tolerance: Shredders handle metal, sand, and paper better than high-speed compactors.

- Versatility: Can switch between rigid sizes (pipes, lumps) and film (with the right screen) without major retooling.

- Cold Start: No need to “warm up” a compactor pot; the system is ready to run immediately.

Troubleshooting

- “Feeder Jamming”: Bridging in the crammer feeder is common with light film. Solution: Use an agitator in the buffer hopper.

- Screen Blinding: Shredder screens blind easily with wet film. Solution: Use a larger screen (50mm+) and rely on the extruder for final mixing.

Comparative Table: Operational Metrics

| Metric | Cutter-Compactor Line | Shredder-Fed Line |

|---|---|---|

| Start-Up Time | 15-30 mins (Heat-up phase) | Instant (Cold feed) |

| Operator Skill | High (Requires balancing heat/speed) | Moderate (Mechanical focus) |

| Maintenance | Blade Sharpening (Frequent) | Knife Rotation (Periodic) |

| Energy Efficiency | ~0.30 kWh/kg | ~0.38 kWh/kg (Due to cold feed) |

| Floor Space | Compact (Integrated) | Large (Modular components) |

Engineer’s Recommendation

If your facility processes 80% film/fiber, the Cutter-Compactor is the superior choice for energy efficiency and throughput stability.

If your facility handles mixed rigid/flexible streams or high contamination levels, the Shredder-Fed architecture provides the necessary robustness and flexibility.

FAQ

Can a Cutter-Compactor run rigid plastics?

Yes, but it’s inefficient. Rigid parts are noisy and wear the blades rapidly. It is designed for thin-walled materials.

How often do I change shredder knives?

For clean plastic, square knives can last 500-1000 hours per edge (4 edges total). For contaminated post-consumer waste, this drops significantly.

Which system produces better pellets?

The Cutter-Compactor generally yields better pellets for film because the “gentle melting” preserves the polymer chains, resulting in higher tensile strength in the recycled product.

References

[1] “Energy Efficiency in Plastic Recycling,” Plastic Recyclers Europe. Energy Efficiency in Plastic Recycling

[2] “Extrusion Feeding Systems,” Plastics Engineering Handbook. Extrusion Feeding Systems