High-Efficiency Debaler for PET Bottle Bales

Automate the first, most critical step of your PET recycling line. Our robust debaler breaks down tightly compacted bales, eliminating manual labor and creating a continuous, uninterrupted flow of material to your sorting and washing line.

Request a Custom QuoteCore Advantages

Boost Plant Throughput

Eliminates the initial bottleneck of manual bale opening, ensuring a steady and consistent feed to your entire line.

Drastically Cut Labor Costs

Replaces slow, expensive, and physically demanding manual labor with a fully automated, efficient process.

Enhance Worker Safety

Automates a hazardous task, removing the risks associated with manually cutting high-tension metal wires.

From Production Bottleneck to Competitive Edge

Common Industry Headaches

- High labor costs and staffing challenges associated with manual bale breaking.

- Inconsistent material flow leads to downstream equipment running empty or being overloaded.

- Significant risk of injury to workers cutting wires under high tension.

The Automated Debaler Solution

- A one-time investment that delivers continuous returns by minimizing payroll expenses.

- Provides a steady, predictable stream of loosened bottles, optimizing the entire line's efficiency.

- A fully enclosed, automated process creates a much safer working environment.

Simple Operation, Powerful Results

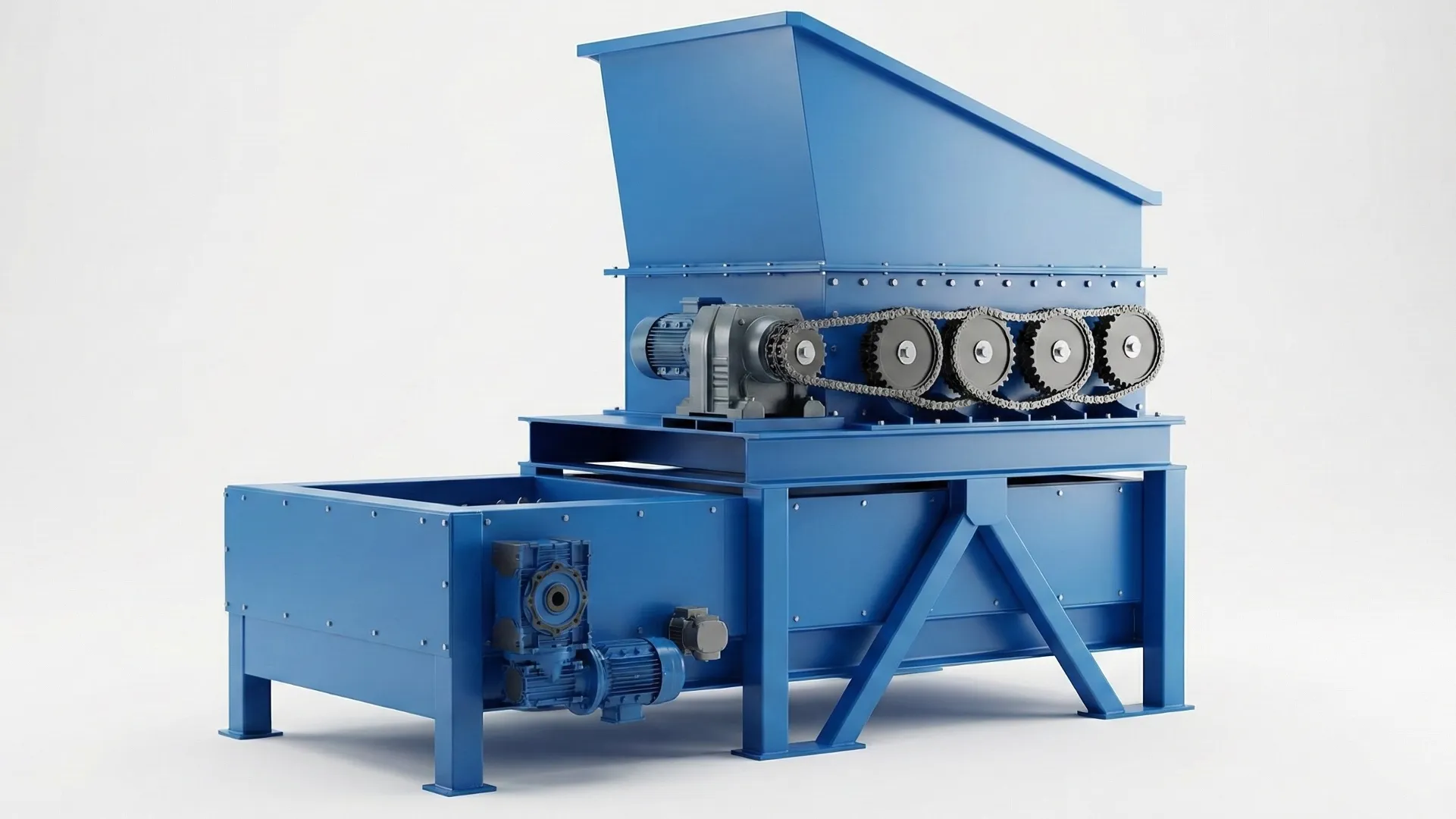

1. Bale Loading

Using a forklift, a full, compacted bale of PET bottles is dropped directly into the vertical infeed hopper.

2. Hook Engagement

Slow-moving, high-torque hooks mounted on a robust drum engage with the bale's binding wires.

3. Bale Deconstruction

As the drum rotates, the hooks pull and tear the wires, causing the highly-compacted bale to burst apart.

4. Material Discharge

The loosened bottles fall onto an integrated discharge conveyor below, feeding the next stage of the recycling line.

The Debaler Advantage

| Feature | Manual Bale Opening | Automated Debaler |

|---|---|---|

| Processing Speed | Slow & Inconsistent | Fast & Continuous |

| Labor Cost | High & Ongoing | Minimal / One-Time Cost |

| Worker Safety | High Risk of Injury | Enclosed & Safe |

| Line Efficiency | Creates Bottlenecks | Optimizes Flow |

Equipment Gallery

Technical Specifications

| Feeder Dimensions | 1450mm x 1650mm |

|---|---|

| Main Motor Power | 5.5 KW |

| Conveyor Motor Power | 7.5 KW |

| Construction | Heavy-duty carbon steel frame |

| Key Feature | Vertical feeding system with slow-moving hook drum |

Frequently Asked Questions

What is the typical lead time for a debaler?

What kind of maintenance is required?

Can this machine handle bales other than PET bottles?

What Our Clients Are Saying

We replaced two full-time positions dedicated to manually cutting bales. This machine paid for itself in less than a year just on labor savings alone. It's a workhorse.

Recycling Plant Manager

Our biggest problem was inconsistent flow to the sorting line. The debaler solved that on day one. Now our entire plant runs smoother and more predictably.

Director of Operations

Safety was our main concern with manual bale opening. Installing the debaler has given us peace of mind and created a much safer environment for our team.

Health & Safety Officer

Automate Your Infeed. Unlock Your Plant's Potential.

Contact our specialists today to learn how the debaler can streamline your operations, reduce costs, and improve safety.