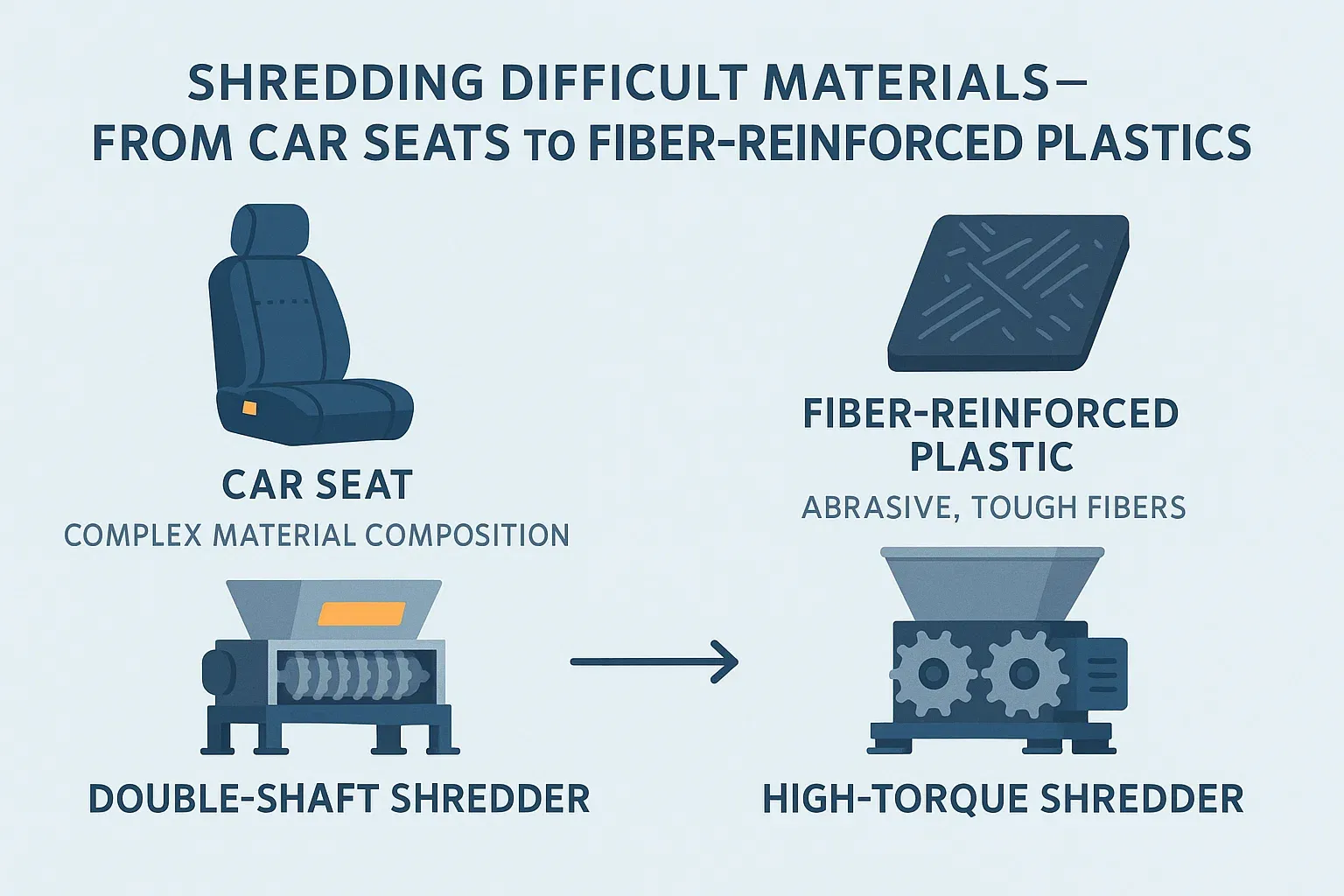

Some materials fight back. Shredding a PET bottle is trivial; shredding a car seat with a steel frame, polyurethane foam, and polyester fabric is an engineering challenge. This guide details the machine configurations required for the toughest materials in the recycling industry.

Related equipment: double shaft shredder (plastic & metal), heavy-duty metal shredder.

1. Car Seats (The “Sandwich” Problem)

Challenge: A mix of ductile fabric, soft foam, and rigid steel.

* Failure Mode: High-speed shredders jam instantly on the steel frame. Single-shaft shredders wrap the fabric around the rotor.

* Solution: Twin-Shaft Shear Shredder (Low Speed, High Torque).

* Configuration: 10-20 RPM. Massive torque (100,000 Nm+).

* Action: The hooked blades pierce the foam and rip the steel frame apart. The slow speed prevents sparking (fire risk).

2. Fiber-Reinforced Plastics (FRP / Wind Turbine Blades)

Challenge: Glass fibers are harder than tool steel.

* Failure Mode: Rapid abrasive wear. A standard D2 rotor will look like a smooth pipe after 100 hours.

* Solution: Hardfaced Rotor + Carbide Knives.

* Metallurgy: The entire rotor body is welded with a Tungsten Carbide matrix (“Waffle Pattern”).

* Knives: Solid Carbide inserts brazed onto steel carriers.

* Dust Control: FRP dust is a carcinogen. Negative pressure air filtration is mandatory.

3. Airbags and Seatbelts

Challenge: Explosive propellants (Airbags) and extreme tensile strength (Seatbelts).

* Failure Mode: Explosions in the chamber; Nylon melting/winding.

* Solution: Underwater Shredding or Nitrogen Inerting.

* Safety: The cutting chamber is flooded or purged with Nitrogen to prevent ignition of undeployed airbag propellant.

* Geometry: Seatbelts require a “Scissor Cut” with zero gap (<0.2mm) to prevent winding.

4. Ghost Gear (Discarded Fishing Nets)

Challenge: Ultra-high MWPE (Dyneema) ropes that float and tangle.

* Failure Mode: Wraps around the rotor bearing housing, destroying seals.

* Solution: Anti-Winding Spline Rotor.

* Design: The rotor shaft has raised “splines” that prevent ropes from tightening.

* Protection: Physical “Labyrinth Rings” bolted to the rotor ends to shield the bearings.

Summary Checklist

| Material | Machine Type | Blade Tech | Critical Feature |

|---|---|---|---|

| Car Seats | Twin-Shaft Shear | Surface Hardened | High Torque / Reverse |

| Wind Blades | Single-Shaft | Carbide Tipped | Hardfaced Rotor |

| Airbags | Shear Shredder | Non-Sparking | Water/Nitrogen Deluge |

| Fishing Nets | Single-Shaft | D2 / H13 | Spline Rotor / Anti-Wind |

References

[1] “Recycling of Wind Turbine Blades,” Composites World. Recycling of Wind Turbine Blades

[2] “Automotive Shredder Residue (ASR) Processing,” Waste Management Journal. Automotive Shredder Residue (ASR) Processing