Dans le paysage moderne du recyclage, la demande de machines efficaces et fiables n'a jamais été aussi forte. La durabilité étant au cœur de la fabrication industrielle, la sécurité et la fiabilité des équipements sont garanties. broyeur de fibres est essentielle pour maintenir la productivité et protéger les équipements et le personnel. Machine Energycle, nous comprenons les subtilités du recyclage textile et nous nous engageons à aider nos clients à optimiser leurs performances tout en respectant les normes de sécurité les plus élevées.

Comprendre le rôle d'un broyeur de fibres

UN broyeur de fibres, également connu sous le nom de déchiqueteur de textiles, est conçu pour traiter une variété de matières textiles post-consommation et post-industrielles, telles que le coton, le polyester, le nylon et les tissus mélangés. Il s'agit d'un élément essentiel du cycle de recyclage, décomposant les déchets en éléments gérables pouvant être réutilisés ou transformés en nouveaux matériaux.

Stratégies clés pour garantir la sécurité et la fiabilité

Entretien et inspections de routine

Une inspection régulière constitue la première ligne de défense contre les pannes mécaniques. Un entretien régulier permet de détecter les premiers signes d'usure et de réduire ainsi le risque de pannes imprévues. Machine Energycle, nos broyeurs sont équipés de panneaux de maintenance facilement accessibles pour simplifier ce processus.

Liste de contrôle pour l'inspection de routine :

- Vérifiez le tranchant et l'usure des lames de coupe

- Inspecter le fonctionnement du moteur et l'alignement de la courroie

- Assurez-vous que les capteurs et les verrouillages de sécurité sont opérationnels

- Éliminer toute accumulation de matériau dans la goulotte d'alimentation

Composants et conception de haute qualité

La durabilité du broyeur de fibres a un impact direct sur la disponibilité opérationnelle. L'utilisation de lames en acier trempé et d'arbres renforcés améliore la capacité du broyeur à traiter des matériaux denses. Machine EnergycleNous concevons chaque broyeur textile pour résister à des charges élevées, garantissant des performances constantes sur différents types de matériaux.

Caractéristiques de sécurité et formation des opérateurs

Les destructeurs de documents modernes doivent respecter des normes de sécurité strictes. Voici quelques caractéristiques clés à prendre en compte :

- Systèmes d'arrêt d'urgence

- Protection automatique contre les surcharges

- Verrouillages de sécurité

- Chambres de coupe fermées

Une formation adéquate des opérateurs de machines est tout aussi cruciale. La connaissance des manuels d'utilisation et des procédures de sécurité garantit une intervention plus rapide en cas d'urgence et favorise une utilisation correcte.

Surveillance et automatisation intelligentes

Modèles avancés de Machine Energycle Intégrer des systèmes de contrôle intelligents qui surveillent le couple, la vitesse et la température. Ces systèmes fournissent des alertes en temps réel, permettant une maintenance prédictive et réduisant les temps d'arrêt.

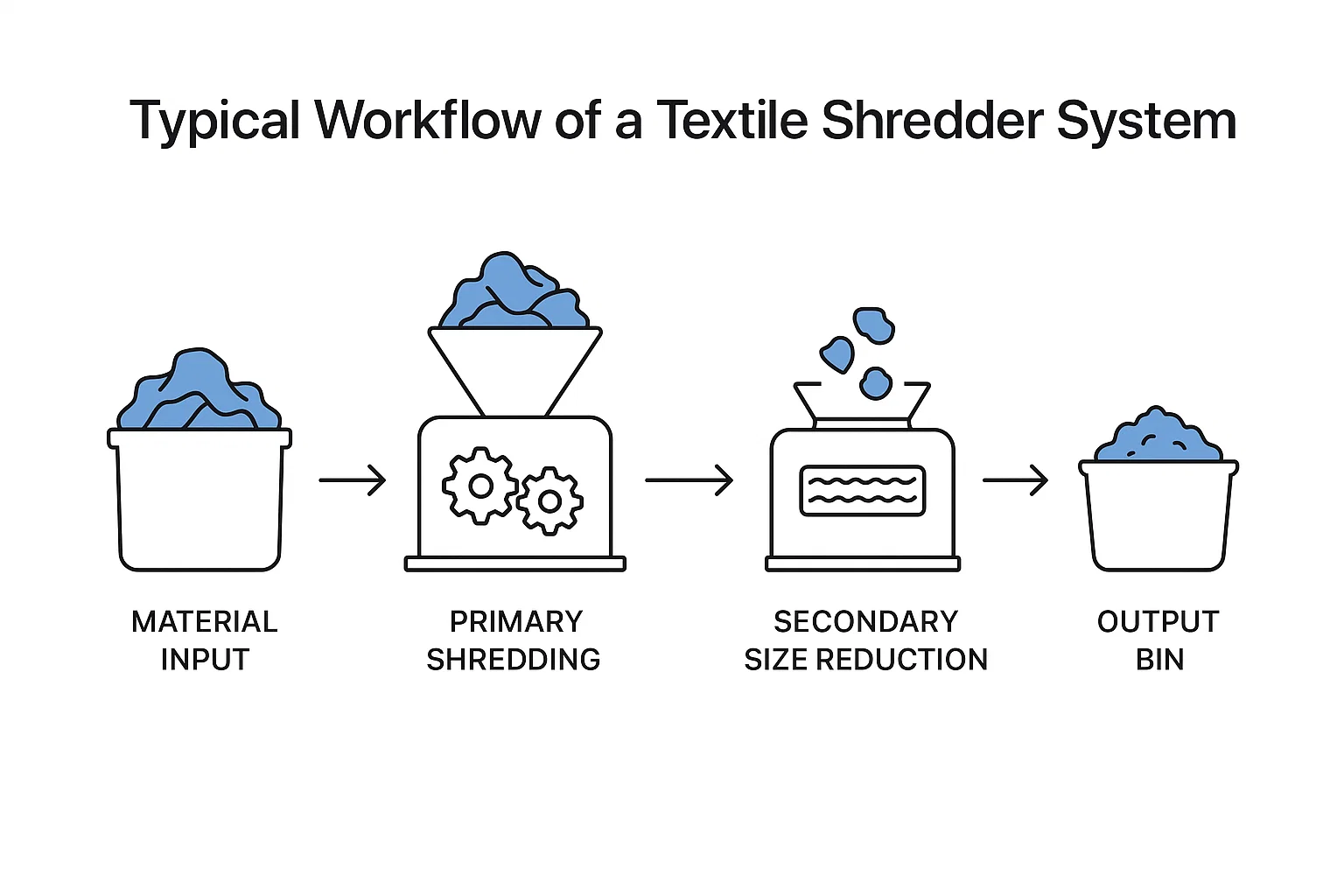

Flux de travail typique d'un système de déchiquetage de textiles

Avantages d'un équipement fiable de déchiquetage de fibres

Un broyeur de fibres bien entretenu et utilisé en toute sécurité offre de nombreux avantages :

- Réduction des temps d'arrêt des machines

- Augmentation du débit

- Des coûts opérationnels réduits

- Sécurité renforcée des travailleurs

- Amélioration de la qualité du recyclage et de la pureté des matériaux

Pourquoi choisir la machine Energycle ?

Avec des décennies d'expérience dans le recyclage des déchets textiles, Machine Energycle Nous proposons des solutions de pointe alliant innovation et fiabilité. Nos destructeurs de textiles sont conçus pour des opérations à haut volume et à haute efficacité et bénéficient d'options d'assistance et de personnalisation de pointe.

Découvrez nos solutions de déchiquetage textile : Broyeur à arbre unique pour déchets textiles/tapis

Foires aux questions (FAQ)

Q1 : Quels matériaux un broyeur de fibres peut-il traiter ?

R : Les déchiqueteurs de fibres Energycle peuvent traiter divers textiles, notamment le coton, la laine, le polyester, le denim et les mélanges synthétiques.

Q2 : À quelle fréquence dois-je entretenir mon destructeur de textiles ?

R : Nous recommandons des inspections de routine toutes les 100 heures de fonctionnement et un affûtage ou un remplacement de la lame si nécessaire.

Q3 : Les destructeurs Energycle sont-ils conformes aux normes CE ou à d'autres normes internationales ?

R : Oui, tous les destructeurs Energycle sont conformes aux normes de sécurité CE et autres normes de sécurité industrielles pertinentes pour les États-Unis et l'Europe.

Q4 : Les broyeurs peuvent-ils être intégrés à une ligne de production existante ?

R : Absolument. Nos machines sont conçues pour être modulaires et s'intègrent parfaitement aux équipements existants.

Contactez-nous aujourd'hui

Prêt à améliorer vos capacités de transformation textile ? Contactez-nous Machine Energycle Contactez-nous dès aujourd'hui pour discuter de vos besoins ou demander un devis personnalisé. Notre équipe est là pour vous accompagner dans votre réussite grâce à des solutions de déchiquetage de fibres fiables, efficaces et sûres.

Visitez-nous à SEO Keywords: energycle, site de rencontre, rencontre en ligne, dating, célibataires, rencontre amoureuse, chat en ligne, inscription gratuite ou contactez votre représentant Energycle local.