Fully Automatic Horizontal Baler

Engineered for high-volume, continuous operation, our automatic baler transforms loose waste like cardboard, paper, and plastics into dense, uniform bales to streamline your recycling workflow.

Maximize Your Recycling Efficiency

Our balers are designed to reduce labor costs, increase throughput, and produce high-quality bales that maximize your return on recycled materials.

Fully Automated Operation

With photoelectric sensors and an automatic tying system, the baler operates continuously with minimal human intervention, freeing up your staff for other tasks.

High-Density, Uniform Bales

Achieve industry-leading bale density thanks to a powerful hydraulic system and anti-slide design, significantly reducing storage and transportation costs.

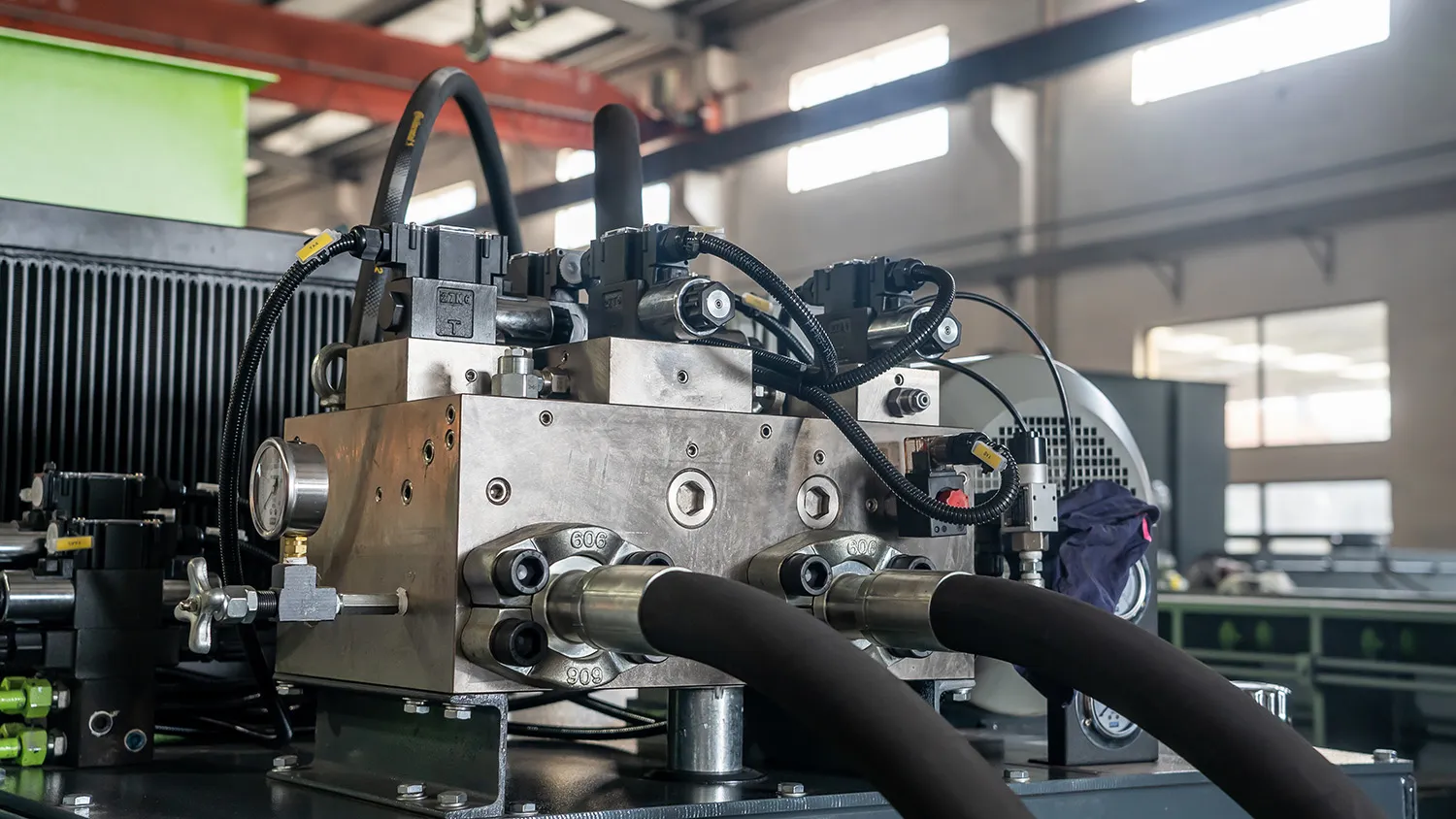

Robust & Reliable Construction

Built with a heavy-duty frame, precision-machined components, and a premium hydraulic system for exceptional durability and sustained performance in demanding environments.

Engineered for Peak Performance

Every component is designed to enhance efficiency, extend service life, and simplify operation and maintenance.

Automatic Tying & Tensioning

Rapid tying mechanism securely binds bales, while the auto-tensioning feature ensures consistent, "brick-like" density for all materials.

Advanced Hydraulic System

Features a differential technique for faster cycle times and lower energy consumption, coupled with a trunnion-mounted main cylinder to maximize seal lifespan.

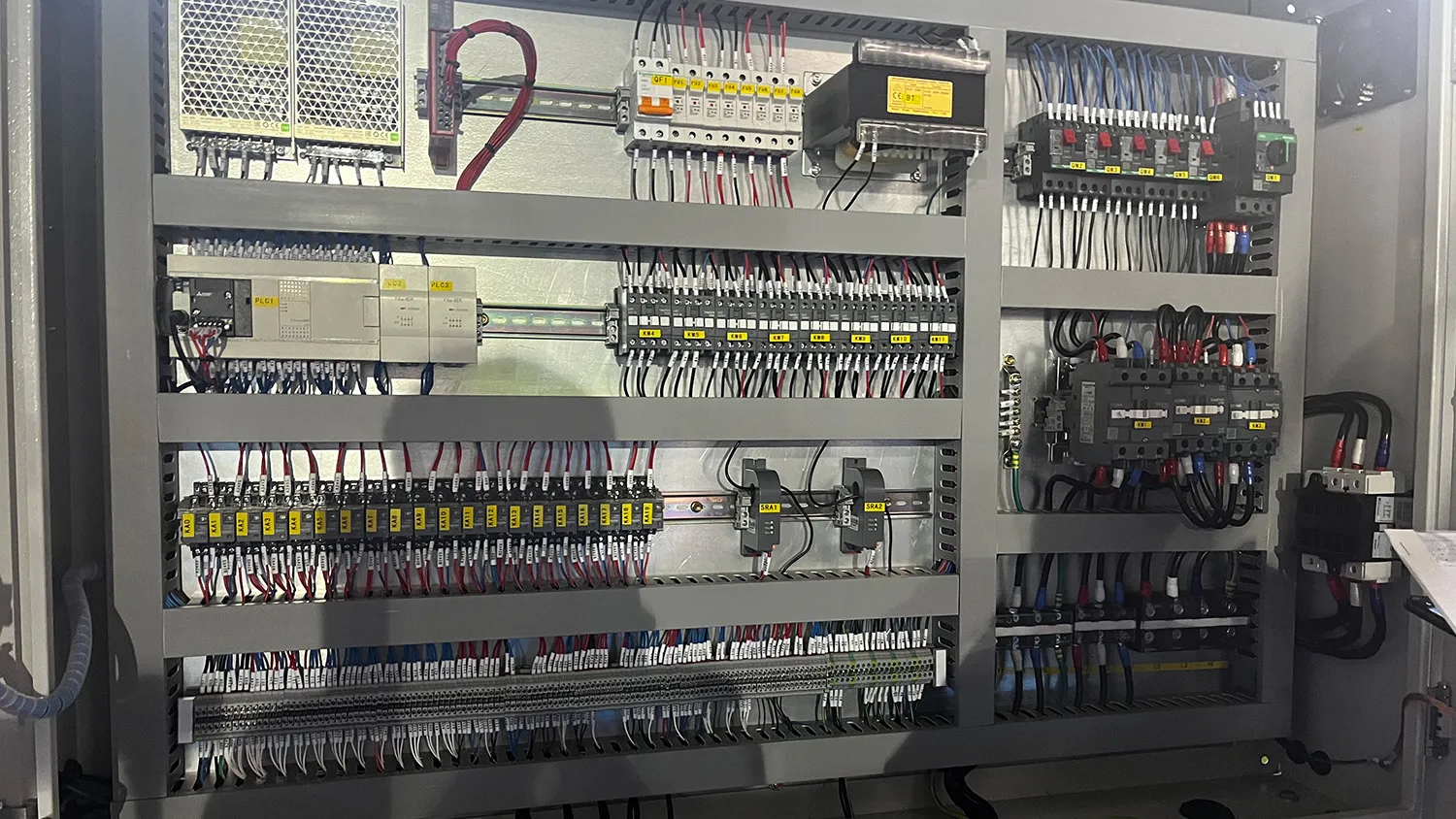

Intelligent Controls & Diagnostics

A user-friendly PLC system allows for adjustable bale length and features a built-in error detection system for rapid troubleshooting and increased uptime.

Machine Gallery

Technical Specifications

| Model | RTM-600W11075-30 | RTM-800W11075-50 |

|---|---|---|

| Main Cylinder Force | 60 tons | 80 tons |

| Main Motor Power | 22 kW | 37.5 kW |

| Cycle Time (No Load) | 24 sec | 16 sec |

| Feed Opening (L×W) | 1600 × 1050 mm | 1600 × 1050 mm |

| Bale Size (W×H) | 1100 × 750 mm | 1100 × 750 mm |

| Bale Length | Adjustable | Adjustable |

| Bale Density (OCC) | 400–500 kg/m³ | 420–500 kg/m³ |

| Throughput (OCC) | 3–7 tons/hr | 4–8 tons/hr |

| Tying Wires | 4 lines | 4 lines |

| Wire Diameter | Ø 2.7–3.0 mm | Ø 2.7–3.0 mm |

| Machine Weight | Approx. 13 tons | Approx. 14 tons |

| Feeding Method | Conveyor Belt | Conveyor Belt |

Frequently Asked Questions

What's the difference between a horizontal and vertical baler?

Horizontal balers are designed for large-scale, continuous operations. They are fed by a conveyor, compress material horizontally, and tie bales automatically. Vertical balers are better for smaller waste volumes, require manual loading and tying, and have a smaller footprint.

How do I determine the right baler size for my facility?

The right size depends on three key factors: the type of material you're processing, the volume (tons per hour) you need to handle, and your desired bale density. Contact our team with these details, and we can recommend the perfect model for your needs.

What kind of site preparation is required for installation?

Our horizontal balers are built on a robust, integrated frame and only require a flat, reinforced concrete surface capable of supporting the machine's weight. You will also need to arrange for the appropriate electrical power supply to the control panel.

Get a Quote for Your Baling Operation

Tell us about your material types, volume requirements, and facility layout. We will provide a comprehensive quote and system drawing tailored to your specific needs.

Comments are closed.