As industries increasingly commit to sustainable practices, PET recycling machines have emerged as essential tools in tackling plastic waste. These advanced systems not only embody environmental responsibility but also represent a critical shift towards efficient, large-scale plastic recovery.

In this guide, we explore the core components of a PET recycling line, highlighting the technology and processes that enable the transformation of post-consumer PET waste into valuable, reusable materials.

What Is a PET Recycling Machine?

PET (Polyethylene Terephthalate) recycling machines are engineered to process used plastic bottles and containers, converting them into high-quality PET flakes or pellets. These recycled outputs can be repurposed into textiles, food-grade packaging, and industrial products, contributing directly to a circular economy.

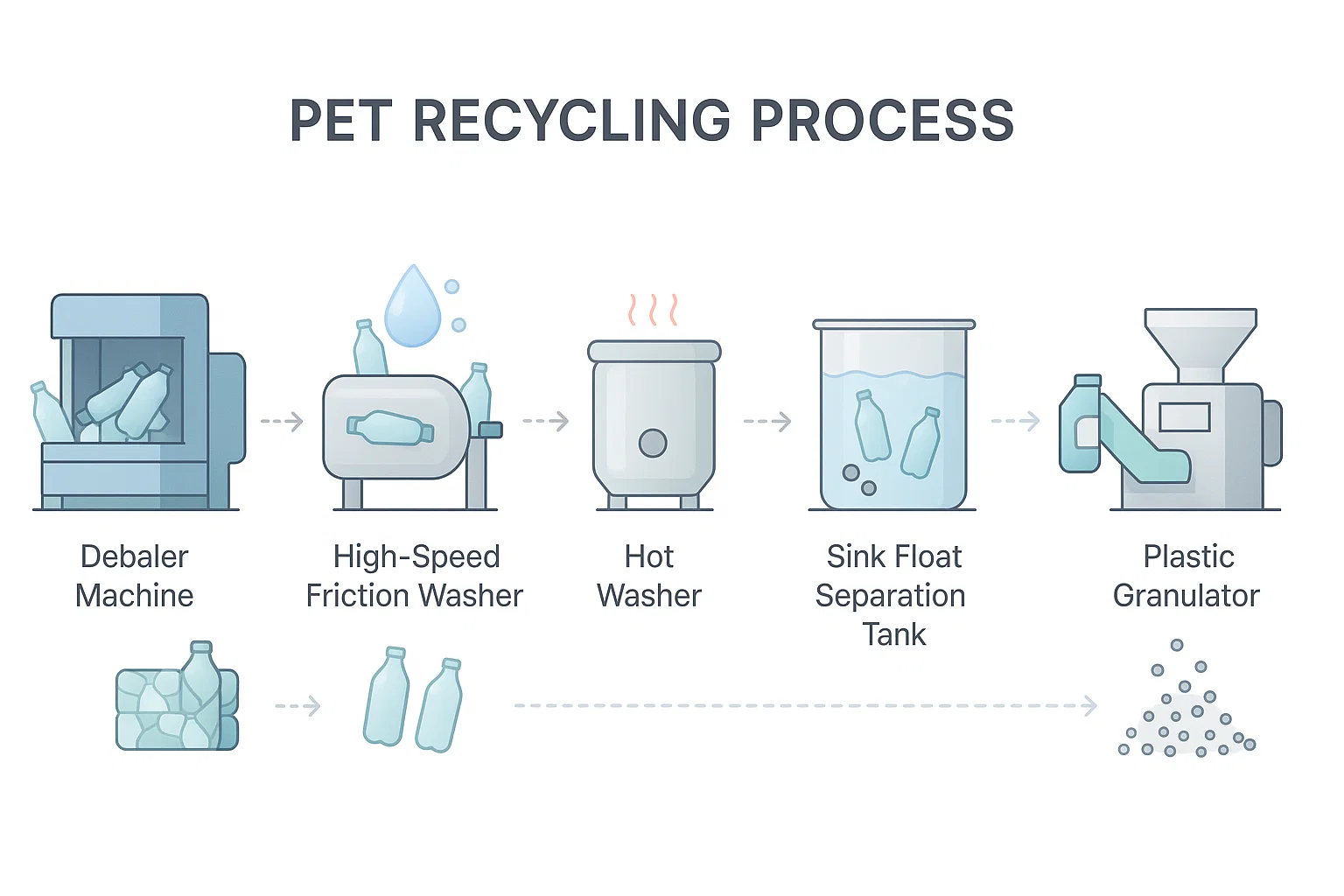

A complete PET recycling system typically includes several specialised machines, each designed to perform a distinct role with maximum efficiency. Let’s examine them in sequence.

1. Debaler Machine – Starting the Recycling Process

The recycling process begins with the debaler machine, which breaks apart densely compacted bales of PET bottles received from collection centres. This machine separates the bottles and feeds them into the line for individual inspection and sorting.

Why it matters: Without proper debaling, downstream equipment can jam or operate inefficiently. This machine ensures consistent flow and throughput from the very beginning.

2. High-Speed Friction Washer – Intensive Surface Cleaning

Next, the bottles undergo mechanical cleaning in the high-speed friction washer. Spinning at high velocities, it scrubs the PET surfaces to remove labels, glue residues, food traces, and dirt.

Key benefit: High-speed friction ensures that PET flakes are thoroughly cleaned, improving overall purityand downstream performance.

3. Hot Washer – Deep Sterilisation & Decontamination

The hot washer takes the cleaning process a step further by exposing PET flakes to hot water mixed with detergent. This sterilises the plastic and removes oil-based contaminants, adhesives, and organic materials.

Purpose: To ensure the flakes meet hygiene standards, especially for applications requiring food-grade recycled PET (rPET).

4. Sink-Float Separation Tank – Density-Based Material Sorting

Using the principle of density separation, the sink-float tank isolates PET flakes from heavier materials like caps (often HDPE) and foreign contaminants. PET flakes float, while denser impurities sink.

Result: This step significantly enhances material purity, supporting higher recovery rates and consistent output quality.

5. Label Separator – Precision Removal of Residual Contaminants

Despite initial cleaning, some labels and adhesives may persist. The label separator targets these non-PET materials through mechanical and air-based methods.

Engineering insight: This step ensures that only clean PET flakes proceed to final granulation, meeting industrial quality benchmarks for reprocessing.

6. Plastic Pellerizer – Transforming Flakes into Reusable Pellets

Finally, the cleaned and sorted PET flakes are fed into the plastic pelletizer, which grinds them into uniform granules or pellets. These can be directly used in injection moulding, extrusion, or fibre production.

Industry impact: This completes the recycling loop, delivering high-quality raw materials for manufacturing new PET-based products.

Frequently Asked Questions (FAQs)

What materials can a PET recycling machine handle?

PET recycling lines are designed specifically for polyethylene terephthalate (PET) bottles and containers, typically from the beverage, food, and consumer goods sectors.

How does a debaler machine improve recycling efficiency?

By breaking down compacted PET bales, the debaler ensures smooth feeding and sorting, preventing mechanical blockages and enabling higher processing throughput.

Why is a hot washer important for recycled PET quality?

It removes biological and chemical contaminants, making the flakes suitable for high-grade or food-grade applications, depending on the system specifications.

What is the purpose of the sink-float separation process?

It separates PET from materials with different densities, such as caps and labels, thereby ensuring a higher-purity final product.

How does the label separator maintain output standards?

It eliminates residual non-PET components, ensuring that only uncontaminated flakes are converted into pellets, which improves the recyclate’s market value.

What happens to the PET flakes after granulation?

They become PET granules or pellets, ready for reuse in new bottle production, textile fibres, or engineering applications.

Conclusion: PET Recycling Technology for a Sustainable Industrial Future

PET recycling machines are at the heart of modern waste management strategies. Each component—from debaling to granulation—plays a vital role in delivering clean, reusable PET materials that can re-enter the supply chain. For procurement professionals and engineers, investing in a high-efficiency PET recycling line means not only environmental compliance but also cost-effective resource recovery.

As technologies continue to evolve, companies like Energycle are committed to providing cutting-edge recycling solutions that empower industries to minimise waste and maximise value.