Plastic washing lines move a lot of water. If you let water quality drift, you see the impact immediately: dirt redeposits on flakes, pumps clog, friction washers wear faster, and product quality becomes inconsistent. If you discharge dirty water without control, you also risk shutdowns and regulatory penalties.

This guide explains how plastic recycling plants typically treat wash-line wastewater and how to design a stable closed-loop water system.

Quick Takeaways

- Treat wastewater as part of the washing line, not a separate project.

- Remove solids early (screens/settling) before they reach pumps and DAF.

- Design for variability; post-consumer streams change day to day.

- Plan sludge handling; it’s often the limiting factor in real operations.

What “Zero Discharge” Usually Means in Practice

Many recycling plants aim to reuse most wash water to reduce consumption and stabilize operations. In practice, most “closed loop” systems still need: – makeup water (losses from sludge, evaporation, carryover) – blowdown (a controlled purge to prevent dissolved contaminants from building up)

The engineering goal is not lab-grade water. It’s water that keeps washing performance stable and doesn’t redeposit contamination on clean flakes.

What’s in Plastic Recycling Wash Water?

The exact mix depends on your feedstock, but most wash lines see: – heavy solids: sand, glass, stones, grit – suspended solids: paper fibers, fines, microplastics – oils and organics: food residue, detergents, adhesives – chemicals: caustic wash carryover (in hot wash systems)

Different contaminants require different treatment steps—one “magic tank” rarely solves all of them.

What to Test Before You Design Treatment (Sampling That Makes Quotes Comparable)

Wastewater proposals vary wildly because influent assumptions vary wildly. Before you request quotations, collect samples from:

- your dirtiest wash step (often pre-wash or friction wash discharge)

- your rinse step (if you run rinse loops)

- any hot wash discharge (if applicable)

Then ask vendors to size the system around a documented window, not a single “average” number.

| Parameter | Why It Matters | What It Often Indicates in Recycling Wash Water |

|---|---|---|

| TSS / turbidity | Predicts redeposition risk and DAF load | Paper fibers, fines, microplastics, grit carryover |

| Oil & grease | Predicts flotation performance and odor issues | Food residue, oils, adhesives |

| pH | Controls coagulation/floc performance and corrosion risk | Caustic carryover or acidic cleaners |

| Temperature | Affects chemistry, separation, and equipment materials | Hot wash carryover and seasonal variation |

| Conductivity / TDS | Highlights dissolved buildup in closed loops | Detergents, salts, dissolved contaminants |

A Typical Treatment Train (Modular Approach)

| Stage | Main goal | What it targets | Common failure mode |

|---|---|---|---|

| Screening / grit removal | Protect pumps and reduce abrasive load | Rocks, glass, sand, large debris | Grit reaches pumps and wears equipment rapidly |

| Equalization | Stabilize flow and concentration | Daily swings in solids and chemicals | DAF performance drifts with every surge |

| Coagulation/flocculation + DAF | Remove suspended solids and some oil/grease | Paper fibers, fines, microplastics, emulsified oils | Over/under dosing, poor mixing, sludge removal neglected |

| Sludge dewatering | Reduce sludge volume | DAF sludge | Sludge storage becomes the bottleneck |

| Polishing + reuse | Keep wash water stable | Residual solids, oils, pH drift | Redeposition on flakes; odor and water quality swings |

1) Primary screening and grit removal

Goal: keep large debris and grit out of pumps and high-speed equipment.

Common tools: – coarse screens or trommels – grit channels or settling pits

2) Equalization tank

Goal: stabilize flow and concentration swings so downstream treatment runs steadily.

If you skip equalization, your chemical dosing and DAF performance will drift as the incoming stream changes.

3) Coagulation/flocculation + Dissolved Air Flotation (DAF)

Goal: remove suspended solids and part of the oil/grease load.

DAF performance depends on: – correct dosing and mixing – stable flow (equalization helps) – sludge removal discipline (if you let sludge build up, treatment quality drops)

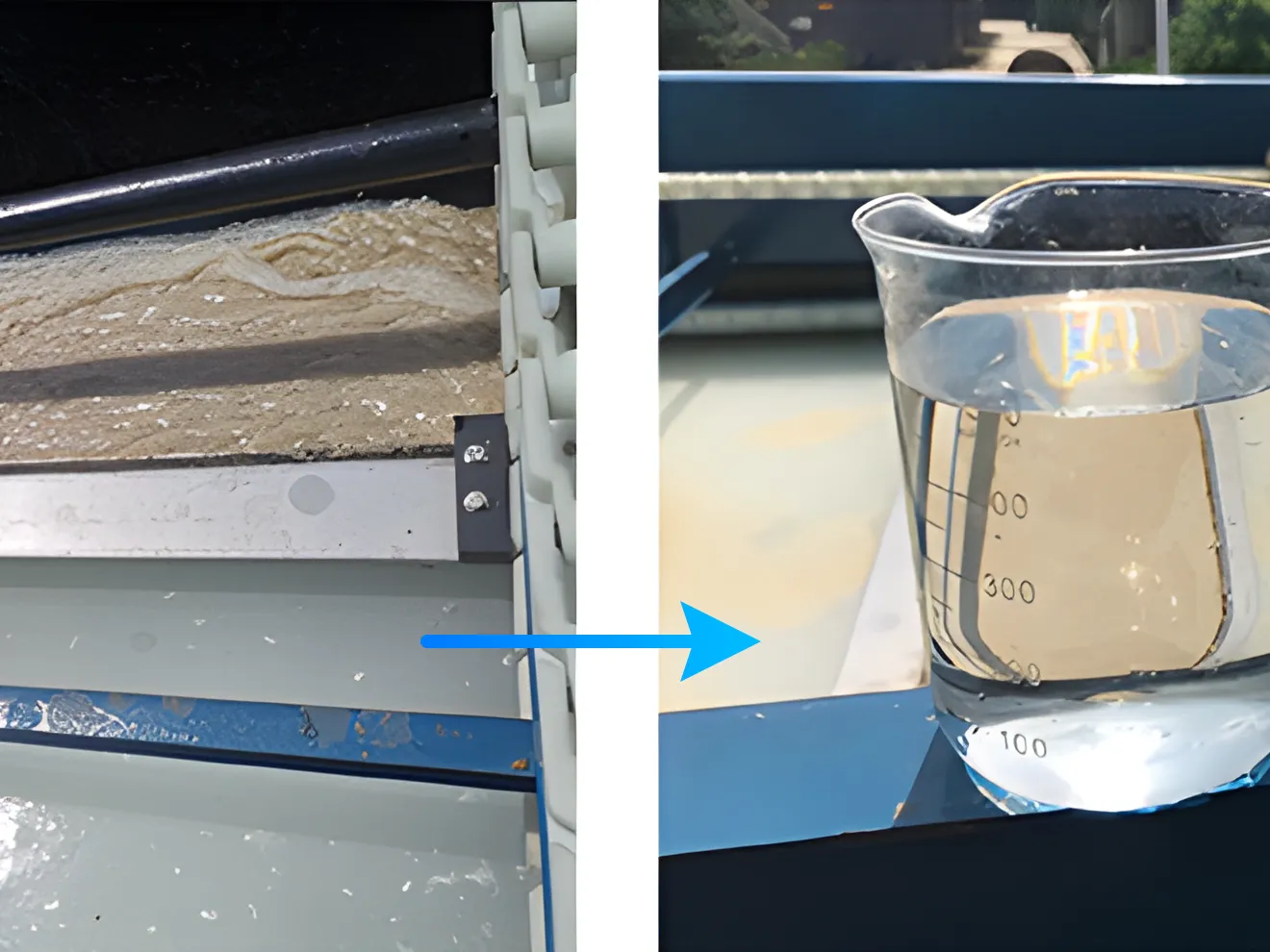

4) Sludge dewatering

DAF sludge contains a lot of water. Dewatering reduces volume and makes disposal practical.

Common approaches: – screw press – filter press – centrifuge (depends on the site and sludge character)

5) Polishing and reuse loop (as needed)

Depending on your quality target, you may add: – sand filters or cartridge filters – oil skimmers – pH control

Your goal is not laboratory-grade water. Your goal is water that keeps washing performance stable without redepositing contamination on clean flakes.

Designing a Closed-Loop Water System That Stays Stable

Good closed-loop systems usually include: – a clear “dirty side” and “clean side” water separation – filtration capacity sized for worst-case contamination – a plan for makeup water and blowdown (you usually need both)

If you’re configuring a full recycling washing system, treat water management as a core module during line design—not something to add after commissioning.

Water stability also shows up in downstream moisture control. If wash water quality drifts, it can increase residue and fines carryover, which makes dewatering and drying less stable. For reference, Energycle’s centrifugal dryer page explains the role of mechanical dewatering as the bridge between wet washing and downstream handling.

What to Ask Wastewater Vendors (So Quotes Are Comparable)

1) What influent assumptions are you using (TSS, oils/grease, pH, detergents, hot wash carryover)?

2) What is the designed sludge volume per day, and what dewatering method is included?

3) What chemicals are required, and what is the dosing control strategy?

4) What is the maintenance plan (screen cleaning, DAF skimming, filter changes)?

5) What happens during “bad days” (high grit, high oils, label glue spikes)?

6) What is included vs excluded (pumps, tanks, control panel, installation, commissioning)?

Compliance Note

If your site discharges any water, requirements depend on local permits and discharge pathways. Even “mostly recycled” systems often need documentation for discharge, sludge handling, and chemical storage.

For U.S. projects, the EPA’s NPDES program is a core reference point for wastewater discharge permitting frameworks. (Source: U.S. EPA NPDES overview)

FAQ (Real Procurement Questions)

Do I need a DAF system, or can I rely on settling tanks?

Settling tanks are great for heavy grit and large solids, but they usually won’t remove lighter suspended solids, emulsified oils, and fine fibers well enough to keep wash water stable. DAF is commonly used when you need consistent removal of suspended solids and some oil/grease, especially when feedstock variability is high. The right design often uses both: settle and screen early to protect pumps, then use DAF for the finer load. Ask vendors to explain what fraction of your solids load is “settleable” vs “floatable,” and require proof based on your wash water samples.

Why is an equalization tank so important?

Because your wash line does not generate a steady wastewater stream. In post-consumer recycling, contamination swings by the hour: grit spikes, label glue spikes, detergent carryover, and occasional oil events. Equalization smooths those swings so chemical dosing and DAF performance stay stable. Without it, you can get a cycle of “good water” and “bad water,” which shows up as redeposition on flakes and frequent interventions. When you compare quotes, ask vendors to define the equalization volume and what “worst-case” variability they are designing for.

What usually becomes the limiting factor in closed-loop wash water systems?

Sludge handling. Even if the water loop looks stable, sludge volume can overwhelm storage and disposal if dewatering is undersized or if upstream screening is weak. Ask for daily sludge volume estimates, percent solids after dewatering, and a realistic disposal plan. Also ask what happens during high-contamination periods: how much extra sludge is produced and where it goes. Many plants solve water quality and then discover their bottleneck is trucking and disposal scheduling. If disposal capacity is uncertain, design extra sludge storage to avoid emergency shutdowns.

How do I prevent wash water from redepositing dirt on clean flakes?

Remove solids early, keep DAF and polishing stages stable, and separate “dirty side” from “clean side” water loops. Redeposition happens when suspended solids remain high or when water quality drifts during spikes. The practical control is monitoring: simple turbidity/TSS indicators, pH control, and routine maintenance of screens and DAF skimming. Also confirm that your dewatering and drying steps are not recycling dirty water back into the clean rinse stage. Design the loop so the cleanest water contacts the cleanest flakes.

Can I truly run zero discharge?

Sometimes, but many plants still require controlled blowdown and makeup water to keep dissolved contaminants from building up. “Zero discharge” can also shift the problem to sludge: all removed contamination has to go somewhere. Before you commit to a no-discharge goal, check local permit requirements, sludge disposal options, and chemical storage requirements. For U.S. facilities that discharge any water, review the EPA’s NPDES permitting framework and align your design with your local authority’s requirements. (Source: U.S. EPA NPDES overview)