Linha de lavagem e peletização de PP/PE reciclado

Converta filmes de PP/PE contaminados e remoa-os em pellets de alta qualidade com um processo limpo e com eficiência energética, projetado para produção consistente e baixa umidade.

Por que escolher esta linha

Pelotas limpas, rendimento estável e configurações flexíveis que se adaptam aos seus materiais e escala.

Saída de alta pureza

Lavagem e separação meticulosas produzem pellets limpos, adequados para aplicações exigentes.

Eficiência Energética

Módulos otimizados e layout inteligente reduzem o consumo de energia e o OPEX.

Modular e personalizável

Configure para corresponder aos níveis de contaminação, restrições de espaço e capacidade alvo.

Do desperdício ao valor: fluxo de processo

Entrada e redução de pré-dimensionamento

Filme PP/PE triturado e remoído preparado para tamanhos estáveis e transportáveis.

Lavagem Intensiva

A limpeza por fricção remove rapidamente etiquetas, papel e contaminantes de superfície.

Separação de Afundamento/Flutuação

A separação por densidade ejeta impurezas pesadas enquanto retém o filme PP/PE.

Secagem Mecânica e Térmica

Desidratação centrífuga ou espremedor + tubos de ar quente atingem umidade ≤ 3–5%.

Pelotização

O sistema de anel de água derrete, filtra e corta em pellets redondos prontos para reutilização.

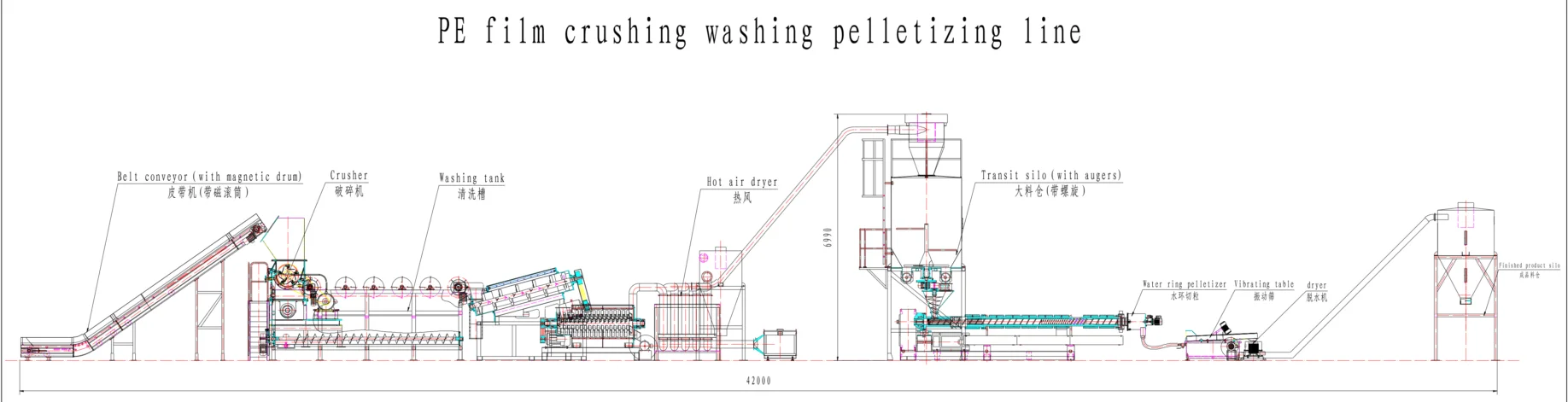

Componentes da linha principal

- Máquina trituradora de plásticoO triturador robusto de eixo único pré-corta o filme para evitar emaranhados e bloqueios.

- Granulador de plástico (moagem úmida)Redução de tamanho para ~10–20 mm com lavagem com água para pré-lavagem.

- Lavadora de fricçãoA lavagem em alta velocidade (≈1000 RPM) remove sujeira incrustada, etiquetas e fibras de papel.

- Tanque de separação de pia/flutuaçãoSeparação de densidade à base de água para descarregar pedras, metais e areia.

- Desidratação centrífugaCentrifuga a água da superfície para reduzir o consumo de energia antes da secagem térmica.

- Desidratação por prensa de parafuso (opcional)A compressão de alta pressão pode substituir os estágios centrífugo e térmico em algumas configurações.

- Secador Térmico e CicloneA secagem por tubo de ar quente e o resfriamento por ciclone removem a umidade residual e partículas finas.

- Silo de produtoTampão de flocos limpos e secos para alimentação estável do peletizador.

- Máquina de peletização de plásticoO peletizador de anel de água derrete, filtra e corta em pellets uniformes e de alta qualidade.

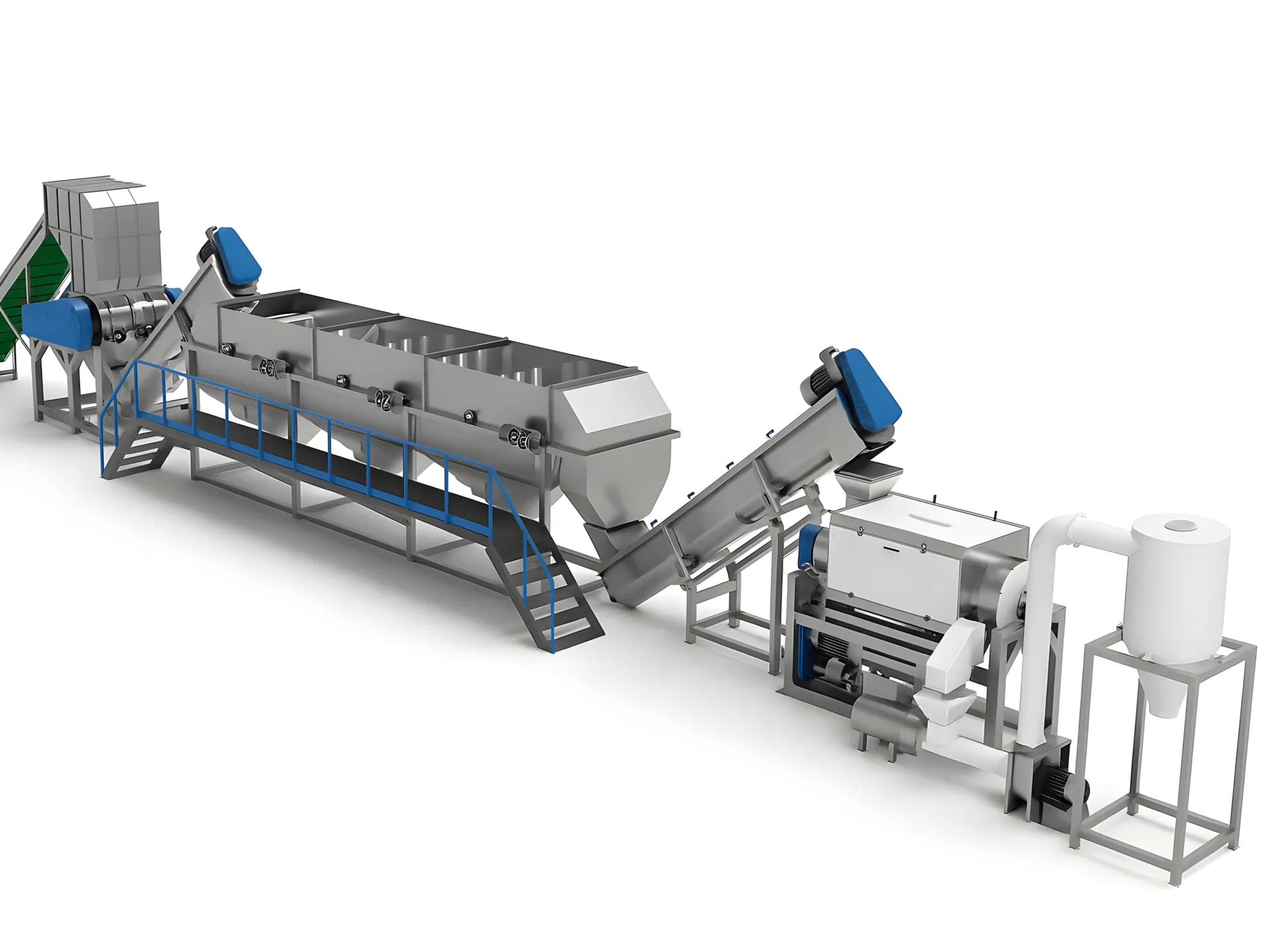

Layout típico

Um arranjo compacto e modular adequado para linhas de 300–2000 kg/h com caminhos de atualização.

Solicite um orçamento

Compartilhe seus materiais de entrada, nível de contaminação e produtividade desejada. Proporemos uma configuração e layout personalizados.

Perguntas frequentes

Quais capacidades estão disponíveis?

As configurações padrão abrangem 300–2000 kg/h. Adaptamos os módulos de linha à sua mistura de materiais, contaminação e pessoal para atingir uma produtividade estável.

Poder e conformidade para UE/EUA?

As configurações da UE normalmente usam 400 V/50 Hz, dos EUA 460 V/60 Hz (outros sob consulta). As máquinas atendem aos requisitos da CE; componentes listados pela UL e IHM em inglês estão disponíveis.

Uso e reciclagem de água?

Sistemas de água em circuito fechado com filtragem minimizam o consumo e o descarte. Podemos integrar DAF e tratamento de lodo para atender às regulamentações locais.

Instalação, comissionamento e treinamento?

Fornecemos desenhos de layout, comissionamento remoto/no local e treinamento para operadores. A instalação típica leva de 2 a 4 semanas, dependendo do tamanho da linha.

Prazo de entrega e envio?

O prazo de entrega geralmente é de 6 a 12 semanas ex-works, dependendo da configuração. Aceitamos FOB/CIF e providenciamos encaixotamento adequado para frete marítimo.

Os comentários estão fechados.