Recycling News

Our plastic film screw press (squeezer/densifier) systems are primarily positioned for Europe and North America, where recyclers face a shared reality: higher labor costs, stricter quality requirements, and rising energy prices. Buyers in these regions typically prioritize equipment that can deliver:

- Stable moisture reduction for washed film (to improve extrusion stability and pellet quality)

- Lower operating costs through efficient dewatering and heat utilization

- Consistent throughput with minimal operator intervention

- Reliable performance on challenging feedstocks (printed film, mixed film, wet or contaminated film)

Europe (EU/UK): Demand is strongest in countries with mature recycling infrastructure and strong packaging-recycling targets—especially Germany, Italy, France, Spain, the Netherlands, Poland, and the UK. These markets often require tighter control of contamination and moisture to meet downstream pellet-quality expectations.

North America (USA/Canada): Many plants are scaling capacity to process more post-consumer film and commercial/industrial film. Common priorities include automation, uptime, and reducing energy use per ton, while maintaining consistent pellet quality for higher-value applications.

What Is a Plastic Film Screw Press System (Squeezer/Densifier)?

A plastic film screw press system is a mechanical dewatering + densifying stage used after a film washing line. It removes free water from washed film using compression and shear, converting wet, fluffy film into a hot, densified, low-moisture output that feeds more reliably into an extruder and pelletizer.

In a typical film line, the screw press sits after:

sorting → shredding → washing → (friction/float rinse) → mechanical dewatering → screw press (squeezer) → extrusion → pelletizing

Compared with basic centrifuges or simple squeeze rollers, a well-designed screw press can deliver:

- Lower and more stable moisture

- Hot, compacted output (densified film)

- Reduced air entrapment before extrusion

- Better line stability under real-world feedstock variation

Why Moisture Control Directly Impacts Costs and Pellet Quality

Moisture is not just “water.” In film recycling, moisture problems often come bundled with:

- detergent residue, fine contaminants, and organic traces

- ink volatiles (printed film)

- uneven drying due to film thickness variation

- water trapped inside folds and multilayer structures

If moisture is unstable, the extruder has to fight it. The result is familiar to any film recycler:

- bubbles/voids in pellets

- unstable melt pressure

- frequent screen changes (contamination + gels)

- lower throughput or forced slowdowns

- higher energy consumption per ton

- more scrap and more operator intervention

A screw press addresses the problem earlier—before the extruder becomes a “dryer.”

Primary Buyers: Who This System Is Built For

This system is designed for facilities that need to turn washed plastic film into stable, high-quality feedstock for extrusion and pelletizing. Typical customers include:

1) Plastic Film Recycling Plants (Post-Consumer & Post-Industrial)

- Operators processing LDPE/LLDPE film, stretch film, packaging film, shopping bags, agricultural film, and mixed flexible plastics

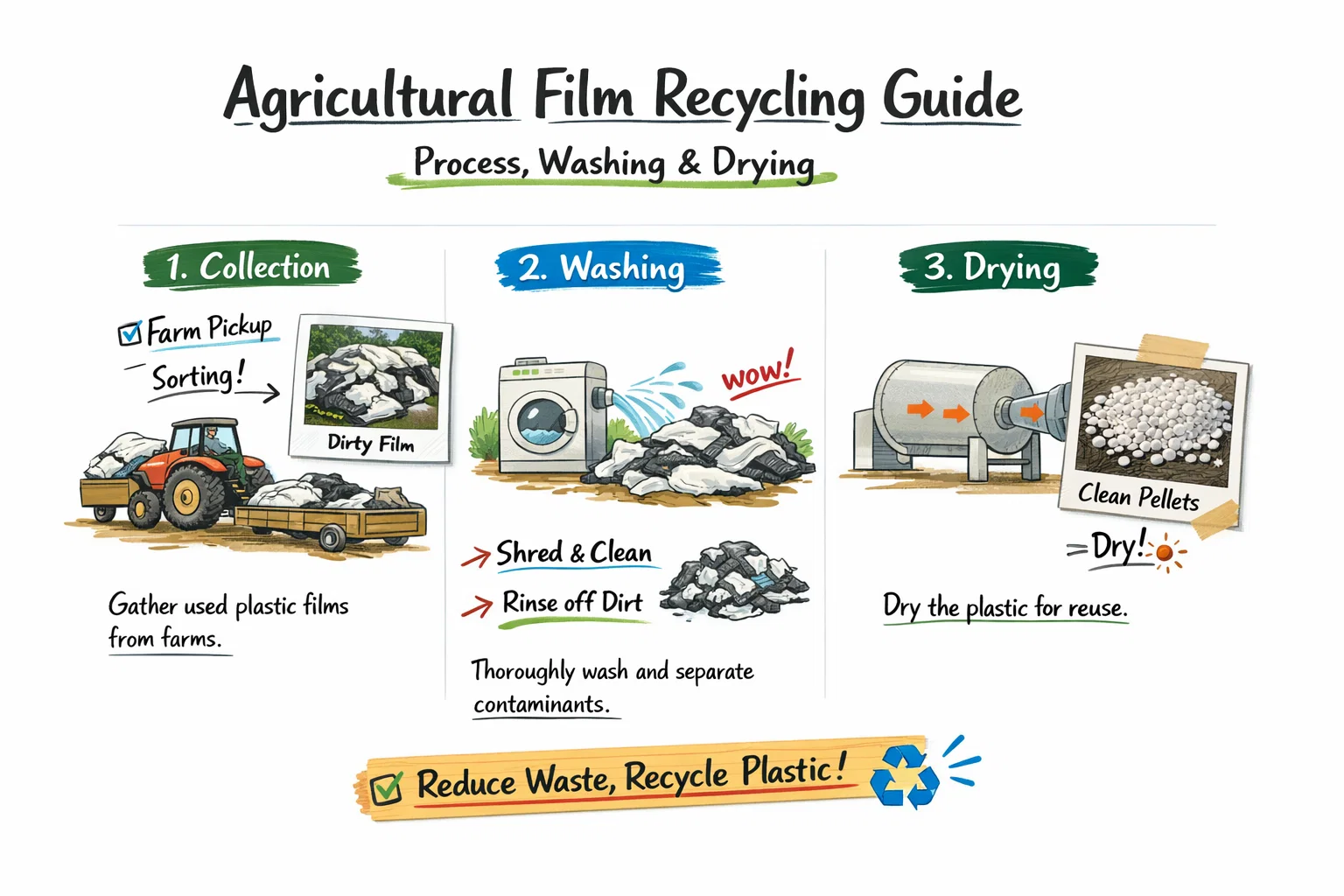

- Plants running a full line: sorting → shredding → washing → dewatering/squeezing → extrusion → pelletizing

2) Pelletizing / Granulation Facilities

- Producers upgrading from basic dewatering to better moisture control for improved melt stability

- Plants aiming for higher pellet consistency, fewer bubbles/voids, and reduced odor caused by residual moisture and volatiles

3) Washing Line Integrators & EPC/Turnkey Line Builders

- Engineering firms and integrators that supply complete film recycling lines and need a reliable squeezing/densifying stage to optimize the whole system’s ROI

4) Waste Management & MRF Operators Expanding into Film Recycling

- Operators adding film recycling capability to capture more value from flexible packaging streams

5) Plastic Converters & Manufacturers with Internal Recycling

- Factories reclaiming in-house film scrap and looking to reduce disposal costs and improve reprocessing efficiency

Typical Decision Makers

In Europe and North America, purchase decisions are usually led by:

- Plant Owners / General Managers (ROI and capacity)

- Operations Managers (uptime, staffing, stability)

- Process Engineers (moisture targets, pellet quality, line integration)

- Maintenance Managers (serviceability and wear parts)

Cost Reduction: Where the Screw Press Delivers Real ROI

When plants evaluate a screw press system, the most important question is not “how it works,” but where the money is saved. In real operations, savings typically come from five areas:

1) Higher Throughput and Fewer Slowdowns

Wet film behaves inconsistently and can overload feeders, cause bridging, or force the extruder to run at lower speed. A screw press outputs dense, warm, consistent material, which improves feeding and stabilizes extrusion.

Practical impact:

- more stable melt pressure

- fewer emergency stops

- improved run time per shift

- easier to maintain target output

2) Lower Energy Use per Ton

If moisture enters the extruder, energy is spent on:

- evaporating water

- compensating for melt instability

- running vacuum systems harder (and longer)

By removing water mechanically (which is generally cheaper than thermal removal), you reduce the energy load downstream.

What improves:

- lower kWh/ton for extrusion

- less thermal shock and fewer temperature swings

- reduced heating demand due to warmer densified feedstock

3) Lower Labor Cost Through Reduced Intervention

Many film lines rely on operator skill to “fight variability.” A screw press reduces the variability itself.

Where labor drops:

- fewer adjustments to feeders and extruder settings

- fewer shutdowns for cleaning and troubleshooting

- less time spent handling fluffy wet film (manual de-clogging, clearing bridges, etc.)

4) Better Pellet Quality (Higher Selling Price or Broader Buyer Access)

Moisture and volatiles are major contributors to:

- bubbles in pellets

- odor and steam-related defects

- poor surface finish

- unstable MFI behavior in downstream processing

Better moisture control can enable:

- more consistent pellet appearance

- fewer customer complaints/returns

- access to higher-value applications (depending on feedstock and overall line design)

5) Reduced Scrap, Downtime, and Maintenance Stress

Unstable wet feeding often increases:

- screen pack load and change frequency

- contamination carryover

- wear on screws, heaters, and downstream components

- “hidden downtime” due to constant micro-stops and re-start cycles

A stable densified feed reduces operational stress across the line.

ROI Analysis: How to Calculate Payback in a Film Recycling Plant

A simple and practical ROI model includes four measurable items:

- Extra output (tons/year) from improved uptime and stable throughput

- Energy savings (kWh/ton or $/ton) from lower drying burden and stable extrusion

- Labor savings ($/year) from reduced intervention and fewer stoppages

- Quality uplift ($/ton) if improved pellets reach better pricing or broader customer acceptance

ROI Formula (Simplified)

Annual Benefit = (Extra Tons × Margin per Ton) + Energy Savings + Labor Savings + Quality Uplift

Payback Period = System Investment / Annual Benefit

Note: The “margin per ton” should be your real margin (selling price minus variable costs), not revenue.

Example ROI Scenario (Illustrative)

To make the math clear, here is an illustrative example (numbers vary by plant and region):

Plant conditions:

- Washed film line producing 3,000–6,000 tons/year

- Current moisture fluctuations cause frequent slowdowns and quality issues

Conservative improvement assumptions after screw press upgrade:

- +8% effective uptime/throughput improvement

- -10% extrusion energy consumption per ton

- -1 operator-hour/day reduction in intervention (or equivalent cost reduction)

- reduced scrap and rework

Even under conservative assumptions, many plants see payback driven by:

- more sellable output (tons)

- fewer stoppages

- lower total operating cost per ton

If you want, we can build a custom ROI sheet using your actual numbers (capacity, kWh rate, labor rate, and scrap rate) so the payback estimate matches your site’s target market.

Key Performance Targets Buyers Ask For

When buyers in the EU/UK and North America evaluate screw press systems, they usually ask:

- Moisture consistency (not just average moisture)

- Throughput stability under mixed film and printed film

- Wear part cost and change intervals

- Ease of cleaning and maintenance access

- Integration compatibility with existing washing and extrusion lines

- Automation features (load control, torque protection, alarm logic)

How the System Integrates Into a Washing + Pelletizing Line

A screw press system is most effective when it is integrated as part of a stable flow:

- Stable feed from washing line (consistent washing and mechanical dewatering upstream)

- Screw press dewatering + densifying (mechanical water removal and compaction)

- Controlled discharge (dense, warm output directly to extruder feeding system)

- Extrusion optimized for melt quality, not forced to act as a dryer

In many upgrades, the screw press becomes the “stabilizer” that allows the extruder to run closer to its designed capacity.

Common Questions (FAQ)

Q1: Can the screw press handle printed film and mixed film?

Yes. Printed film and mixed film typically carry more volatiles and variation. The screw press helps by stabilizing moisture and feeding density, which reduces process shocks downstream.

Q2: Does it replace a dryer?

In many film lines, the screw press reduces or simplifies drying needs. Whether it fully replaces thermal drying depends on:

- your moisture target for extrusion

- your feedstock type and contamination

- your overall line design

Q3: Is it difficult for operators to use?

No. Most systems are built for straightforward operation with:

- load control and torque protection

- clear alarms and interlocks

- stable output that reduces manual intervention

Q4: What matters most for ROI—moisture reduction or densification?

Both matter. Moisture reduction improves melt stability, while densification improves feeding and throughput. The best ROI usually comes from the combination:

- stable moisture + stable feed density + fewer stops

Ready to Reduce Costs and Improve Pellet Stability?

If your plant is processing washed film and you’re fighting:

- unstable extrusion

- bubbles/voids

- downtime from wet feed

- high operating costs per ton

A plastic film screw press system is often one of the fastest ways to improve ROI because it stabilizes the most expensive downstream stage—extrusion and pelletizing.

Contact us with your material type (LDPE/LLDPE/mixed film), capacity target, and current moisture range. We can recommend the right configuration and help you estimate ROI based on your local electricity and labor costs.

This buyer-focused guide explains when a plastic crusher should not be used, how to choose between a crusher and a shredder based on material length, realistic capacity thresholds, and which “heavy-duty” options are often unnecessary.

Designed for recycling professionals, this article helps you avoid costly mistakes and select the right size-reduction solution for your recycling line.

This article explains the seven main types of plastic, which materials are commonly recycled, what recycled plastics are used for, and the typical equipment required for each recycling process. A practical, engineering-focused guide for recyclers, plant operators, and project developers.

This article explains the main applications of PET flakes, common quality grades, and the technical indicators that determine their value—from fiber and sheets to bottle-to-bottle recycling. Ideal for recycling plant owners, equipment buyers, and project investors.

Rigid Plastic Recycling Trends 2026: The Industrial Buyer’s Guide to Profitable Sustainability

The landscape of rigid plastic recycling is shifting dramatically. As we approach 2026, the industry is moving beyond simple "waste reduction" into a highly regulated, profit-driven sector fueled by Extended Producer Responsibility (EPR) laws and global circular economy mandates. For facility managers and recyclers, this is no longer just about being green—it is about operational survival and seizing market share.

Industry Insight: By 2026, the global recycled plastics market is projected to see aggressive growth, driven by new legislation in the US (like WA, CA, NJ) and the EU’s Circular Economy Act. The demand is shifting specifically toward High-Purity rHDPE and rPP that can rival virgin materials.

What Defines "Rigid Plastic" in an Industrial Context?

Before investing in machinery, it is critical to distinguish your material streams. Rigid plastics are dense, chemically resistant polymers that require heavy-duty processing. Unlike flexible films, they shatter or deform under high stress rather than stretch.

Common Industrial Rigid Streams:

- HDPE (High-Density Polyethylene): Detergent bottles, chemical drums, pipes.

- PP (Polypropylene): Car bumpers, battery cases, food containers.

- ABS/PS (Acrylonitrile Butadiene Styrene/Polystyrene): Electronic waste (WEEE) and appliance casings.

Processing these materials requires more than a standard shredder; it demands a calibrated system capable of handling high-impact loads and stubborn contaminants.

Key Trends Shaping Machinery Choices in 2026

1. The Rise of "High-Purity" Washing Lines

The market for low-grade regrind is shrinking. Buyers in 2026 demand 99.9% purity. This trend is driving a technological shift toward Hot Washing and Friction Washing technology.

At Energycle, we are seeing increased demand for integrated washing lines that can strip oils, chemical residues, and labels from rigid plastics (like HDPE milk jugs or PP oil containers) in a single pass. If your pellets smell or contain adhesive residue, they will sell for a fraction of the market price.

2. Automation and AI-Driven Sorting

With labor costs rising globally, the days of manual sorting lines are numbered. Modern recycling plants are integrating Optical Sorters (NIR technology) directly into their washing lines. These systems automatically eject non-target polymers (like a PVC pipe in a PP stream) before they hit the granulator, protecting your machinery and ensuring consistent output quality.

3. Closed-Loop Water & Energy Systems

Sustainability is not just for the plastic; it’s for the process too. 2026 regulations will scrutinize the water footprint of recycling plants. Leading machinery now incorporates:

30%

Less Water Usage via Filtration

VSD

Variable Speed Drives for Energy Savings

Machines equipped with water treatment recycling systems lower your operational overhead significantly over a 5-year period.

4. Handling "Difficult" Rigid Streams (EPR Compliance)

EPR laws are forcing manufacturers to take back difficult items like automotive battery cases and agricultural chemical drums. These are toxic and hard to process. Standard machines fail here. The trend is moving toward specialized Shredder-Granulator Combinations that can withstand heavy abuse and corrosive residues without frequent blade changes.

The Challenges You Will Face (And How to Solve Them)

✅ The Opportunity

- High Margins: High-quality rHDPE pellets are trading at premiums near virgin resin prices.

- Subsidies: Governments are offering grants for upgrading to efficient machinery.

- Scalability: Modular machinery allows you to start with 500kg/h and scale to 2000kg/h.

⚠️ The Obstacles

- Contamination: Paper labels, glue, and metal fragments can destroy extruder screws.

- Inconsistent Feedstock: Mixing different melt indexes causes pelletizing failure.

- Maintenance Costs: Cheap machinery vibrates excessively, leading to bearing failures and downtime.

Best Practices for Sustainable Operations

To ensure your facility remains competitive in 2026, adopt these operational standards:

- Invest in Pre-Shredding: Never feed whole bales directly into a granulator. Use a low-speed, high-torque shredder first to reduce wear.

- Filtration is King: Use dual-piston screen changers on your extruder. This allows you to swap dirty screens without stopping the machine, maintaining 24/7 production.

- Routine Blade Maintenance: Sharp blades produce less dust (fines) and use less energy. Establish a strict sharpening schedule.

💡 2026 Buyer’s Decision Guide

Before you purchase a Rigid Plastic Recycling Machine, ask the manufacturer these questions to ensure E-E-A-T compliance and ROI:

- Does the washing line include a hot washer? (Essential for removing glues and oils from rigid containers).

- What is the steel grade of the screw and barrel? (Look for bimetallic treatment to resist abrasion from dirty plastics).

- Is the water system closed-loop? (Crucial for lowering utility bills and meeting environmental permits).

- Do you offer local commissioning and spare parts? (Downtime kills profit; ensure your partner is accessible).

Why Energycle? The Advantage for Professional Buyers

The recycling industry is flooded with generic machinery that looks good on paper but fails under the stress of 24/7 industrial operation. At Energycle, we don't just sell machines; we engineer turnkey recycling solutions tailored to the 2026 regulatory landscape.

Our Rigid Plastic Washing & Pelletizing Lines are built with heavy-gauge steel and precision-engineered components designed to handle the toughest loads—from HDPE drums to PP crates. We prioritize Intelligent Automation, allowing you to monitor energy consumption and output quality in real-time.

Ready to Upgrade Your Recycling Infrastructure?

Don't let outdated machinery hold your business back. Embrace the 2026 trends with equipment built for efficiency and high-purity output.

Get a Custom Solution Quote