Recycling News

Europe is at the forefront of the global circular economy. With strict environmental regulations, ambitious recycling targets, and rising demand for high-quality recycled plastics, European recycling plants require reliable, compliant, and energy-efficient plastic recycling equipment.

This guide explains what European recyclers look for when investing in plastic recycling machinery—and how to select the right equipment for long-term success.

1. Why European Recycling Plants Have Higher Equipment Requirements

Unlike many other markets, European recycling facilities must operate under tight regulatory, safety, and quality constraints. Equipment decisions are influenced not only by price but also by:

- EU recycling policies and waste management directives

- CE safety and compliance requirements

- Energy efficiency and reduced carbon emissions

- Water consumption and wastewater recovery

- Output quality (especially for food-grade and closed-loop recycling)

As a result, plastic recycling equipment for Europe must be engineered differently, with a stronger focus on automation, process stability, and compliance.

2. Core Plastic Recycling Equipment Used in European Plants

A modern European recycling plant consists of several interconnected systems rather than standalone machines. These systems must work together to ensure consistent quality and high throughput.

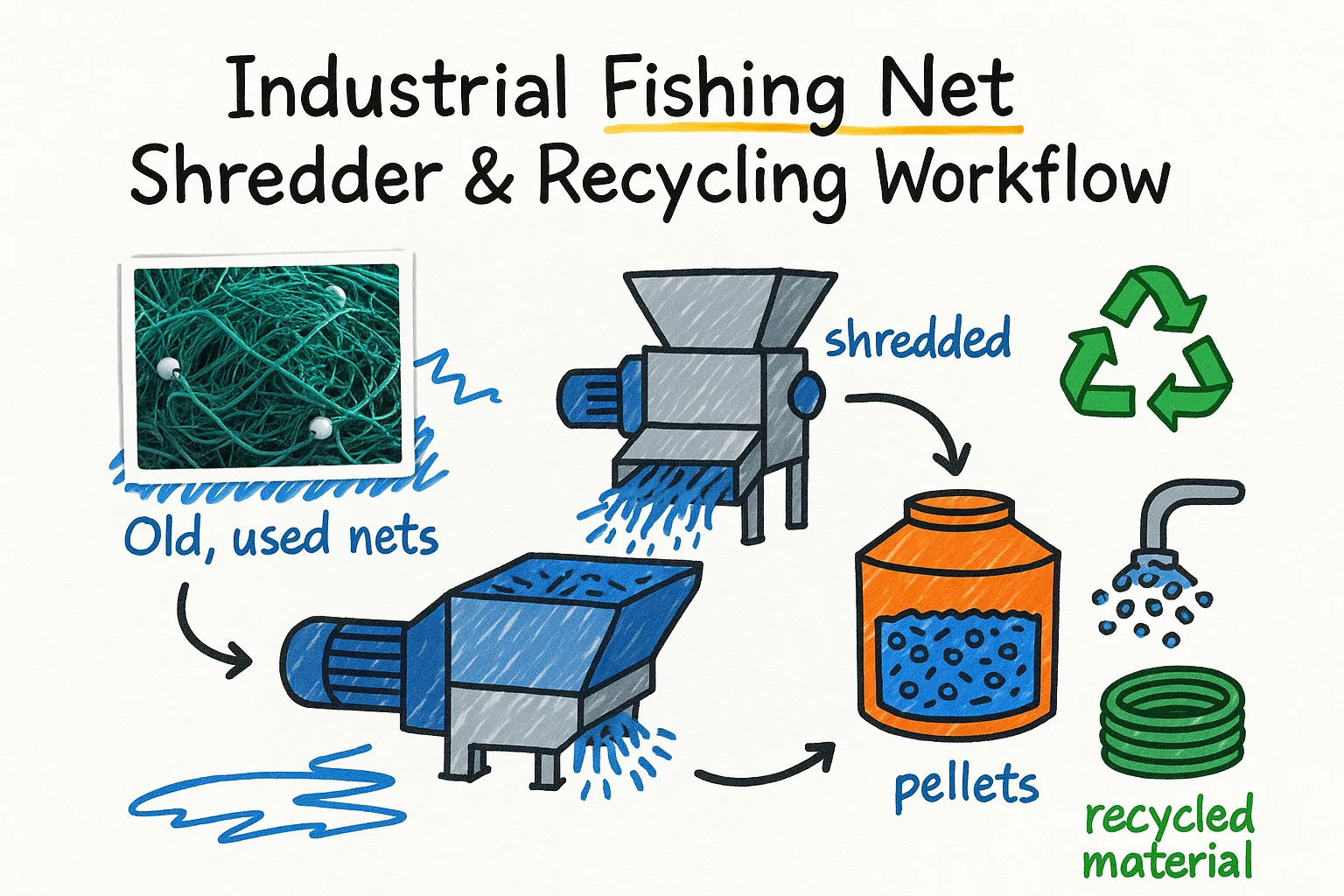

2.1 Shredding and Size Reduction

The first step in many recycling operations is shredding and size reduction. European recyclers often process contaminated post-consumer plastics, so equipment must be robust and flexible enough to handle:

- Bottles, jars, containers

- Films and agricultural plastics

- Mixed polymers and labels

- Occasional metal contamination

Low-speed shredders and heavy-duty granulators ensure controlled size reduction with minimal wear.

2.2 Washing Lines – The Heart of the Plant

Efficient washing is the backbone of any plastic recycling plant. European facilities rely on advanced systems like the Recycling Washing System to deliver clean, dry plastic flakes ready for reprocessing.

Key Washing Line Technologies:

- Pre-washing and drum washing

- Hot washing systems (especially for PET)

- Friction washers

- Sink-float separation tanks

- High-speed centrifugal dryers

Efficient washing lines not only improve output quality but also reduce operating costs by saving water and energy.

2.3 PET Bottle Recycling Systems

PET is one of the most recycled materials in Europe, especially in countries with bottle deposit return schemes. For facilities processing PET, the PET Bottle Recycling System ensures top-tier cleanliness and consistent throughput.

These systems are engineered for:

- High-efficiency hot wash

- Label and adhesive removal

- Effective contaminant separation

- Consistent flake quality ready for further processing

European PET recyclers targeting food-grade or bottle-to-bottle applications place particular emphasis on hot washing and moisture-controlled outputs.

2.4 Rigid Plastic Washing Lines

Beyond bottles and films, rigid plastics like crates, drums, and industrial containers require specialized systems. The Rigid Plastic Washing Line for PP, HDPE, PVC is designed to process these challenging materials with high throughput and thorough cleaning.

These lines typically include:

- Heavy-duty pre-wash

- High-torque friction washers

- Aggressive decontamination systems

- Efficient drying solutions

Rigid plastic washing lines are increasingly in demand in EU markets processing packaging, industrial waste, and consumer goods plastics.

2.5 Drying and Dewatering Systems

After washing, moisture must be removed efficiently to prepare the material for extrusion or pelletizing. European recyclers often require high-performance drying systems such as those outlined on the Drying Systems page.

Effective drying is crucial for:

- Reducing final moisture below 1–3%

- Preparing flakes for consistent extrusion

- Lowering energy costs in downstream processing

3. Compliance and Certification in Europe

3.1 CE Certification and Safety Standards

All plastic recycling equipment installed in Europe must be CE-compliant, covering:

- Mechanical safety and guarding

- Electrical and control system certification

- Emergency stop systems

- Operator safety and ergonomic design

European buyers commonly request full CE documentation before progressing in purchase discussions.

3.2 Food-Grade and Bottle-to-Bottle Requirements

For recyclers aiming at bottle-to-bottle or food-grade PET recycling, additional scrutiny is applied to washing and decontamination processes. Washing systems must deliver consistent cleanliness and moisture control to meet stringent downstream requirements.

4. Energy and Water Efficiency – A Key Buying Factor

European recycling facilities are under constant pressure to reduce operating costs and environmental impact.

When selecting plastic recycling equipment, buyers focus on:

- Power consumption per ton of output

- Water circulation, filtration, and recovery systems

- Heat recovery in hot washing stations

- Automation and real-time process control

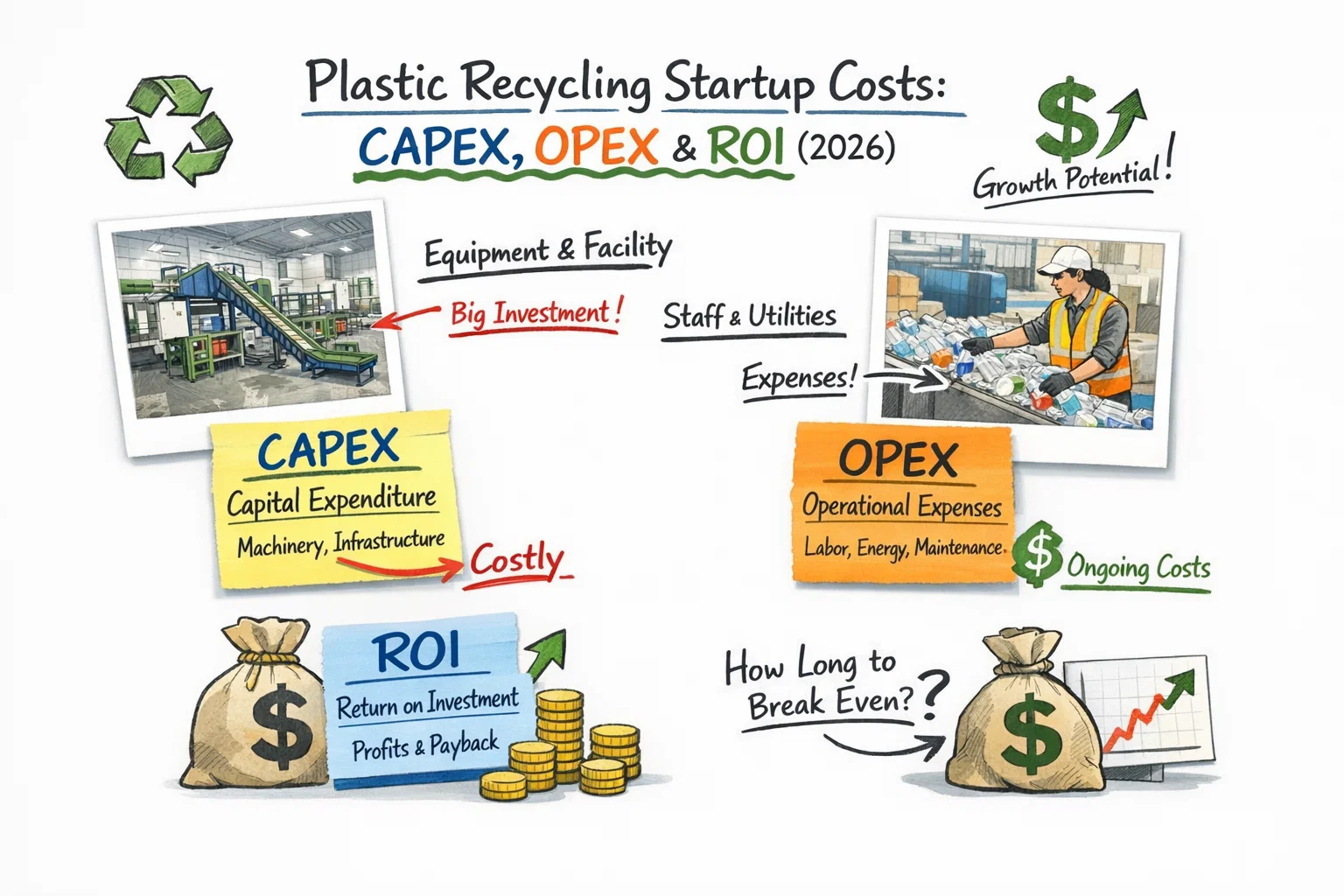

Equipment with optimized energy and water usage not only reduces OPEX but also enhances a plant’s sustainability profile—an important factor for EU funding, certification, and ESG commitments.

5. Turnkey Plastic Recycling Solutions

Many European buyers opt for comprehensive project solutions rather than isolated machines. The Recycling Solutions page highlights complete plant solutions, from initial layout design to installation and after-sales support.

Turnkey solutions typically include:

- Engineering and process design

- Complete equipment integration

- Installation and on-site commissioning

- Operator training and technical support

Such holistic services help recyclers reduce risk, improve uptime, and accelerate ROI.

6. How to Choose the Right Supplier for European Markets

When evaluating suppliers of plastic recycling equipment, experienced European recyclers look for:

- Proven installations in Europe or similar markets

- CE-ready machinery and documentation

- Engineering-led solutions rather than generic machines

- Transparent technical information and process support

- Long-term spare parts availability and service

Selecting the right partner is as important as selecting the right equipment.

7. Final Thoughts

European recycling plants operate in one of the most demanding regulatory and operational environments in the world. Investing in compliant, efficient, and integrated plastic recycling equipment increases profit margins, enhances product quality, and supports long-term sustainability goals.

With advanced washing systems, high-efficiency drying solutions, and turnkey recycling plant options, equipment suppliers can help European recyclers thrive in a competitive, compliance-driven marketplace.

Introduction: The Hidden Value in Woven Polypropylene

In the logistics and manufacturing sectors, Super Sacks—technically known as Flexible Intermediate Bulk Containers (FIBCs)—are the backbone of material transport. From agriculture to mining, these durable woven Polypropylene (PP) bags are indispensable. However, their durability creates a significant challenge at the end of their lifecycle.

In the modern manufacturing landscape, Ethylene-Vinyl Acetate (EVA) is ubiquitous. From the soles of high-performance footwear to critical components in the solar energy sector, this material is prized for its versatility. However, as production volumes soar, so does the volume of industrial scrap and post-consumer waste.

In the modern era of the circular economy, the Plastic Pelletizer is not just a machine; it is the heartbeat of the recycling industry. For plant managers and procurement specialists, understanding this equipment is the difference between operational inefficiency and high-margin profitability.

At Energycle, we engineer machinery that turns plastic waste—often seen as a liability—into high-quality, market-ready raw materials. This guide explores the mechanics of pelletizing technology and why it is the cornerstone of sustainable manufacturing.

Introduction: The Engine of Plastic Recycling

A plastic pelletizer is a specialized industrial machine designed to melt, homogenize, and shape plastic waste (such as films, bottles, and rigid scraps) into uniform pellets. These pellets serve as the "virgin-like" feedstock for manufacturers producing everything from piping to packaging.

For recycling plants, the goal is consistency. A high-quality pelletizer ensures that recycled pellets have the same density, moisture content, and melting index as new materials, allowing them to be sold at a premium.

How Does a Plastic Pelletizer Work?

While the core concept is simple—melt and cut—the engineering behind it determines the quality of your output. Here is the elevated, step-by-step breakdown of the process.

1. Feeding: The Critical First Step

The process begins with feeding plastic scraps, granules, or flakes into the hopper.

- The Challenge: Inconsistent feeding causes surging and uneven pellets.

- The Solution: Modern systems use force-feeders or cutter-compactors to handle lightweight materials like films (PE/PP) effectively. This ensures the extruder screw is always "hungry" but never choked, maximizing throughput.

2. Heating and Melting (Plasticization)

Once the material enters the barrel, it is subjected to intense shear heat and external heating zones.

- The Science: The rotating screw creates friction (shear stress), which does 80% of the melting work.

- Degassing: Crucially, high-end pelletizers feature vacuum degassing zones. This removes moisture and ink volatiles from printed plastics, preventing bubbles and defects in the final pellets.

3. Extrusion and Filtration

The molten plastic, now a thick, viscous fluid, is pushed through a filtration screen before reaching the die.

- Filtration: A hydraulic screen changer filters out contaminants like paper labels, metal, or wood. Without this, the final product would be unusable for high-precision manufacturing.

- Pressure: The melt is then forced through a die head, which acts as the "mold" for the plastic strands.

4. Cooling the Plastic

As the plastic exits the die, it must be cooled immediately to lock in its shape.

- Strand Cooling: In traditional systems, spaghetti-like strands pass through a water bath.

- Die-Face/Water Ring: For materials like PE films, the cutting happens at the die face, and pellets are immediately flung into a water ring for cooling. This reduces the footprint and labor required.

5. Cutting into Uniform Pellets

The final step is sizing.

- Strand Pelletizing: Solidified strands are pulled into a granulator and chipped into cylinders.

- Hot Cut (Die Face): Rotating blades cut the plastic while it is still hot and molten against the die face.

- The Result: Uniform, free-flowing pellets ready for bagging, storage, or immediate sale.

Types of Pelletizing Systems: Which Do You Need?

Selecting the right Plastic Pelletizer depends entirely on your material type (Rigid vs. Film) and moisture levels.

1. Strand Pelletizing Lines

- Best For: Engineering plastics, rigid regrinds (ABS, PA, PC), and high-viscosity materials.

- Pros: Simple operation, easy maintenance, and excellent for compounding.

- Cons: Requires manual lacing of strands during startup.

2. Water Ring / Die-Face Pelletizers

- Best For: Post-consumer film recycling (LDPE, HDPE, PP).

- Pros: Automated startup (no strand lacing), compact footprint, and handles materials with higher melt flow rates effectively.

- Energycle Insight: Our water-ring systems utilize a unique blade design that ensures pellets are cut cleanly without "tails," preventing clustering in the drying silo.

3. Underwater Pelletizers

- Best For: High-volume production and sticky polymers (TPU, TPE).

- Pros: Produces perfectly spherical pellets with high bulk density.

- Cons: Higher initial investment.

Why Energycle? The "Buyer's Advantage"

In a market flooded with generic machinery, Energycle stands out by focusing on Total Cost of Ownership (TCO).

- Screw Geometry: Our screws are designed with specific L/D (Length-to-Diameter) ratios tailored to your material, ensuring lower energy consumption per kilogram of output.

- Durability: We use bimetallic barrels and hardened screws to resist the wear and tear of abrasive recycled materials (like dirty agricultural films).

- Intelligent Control: Our PLC systems allow you to monitor melt temperature and pressure in real-time, reducing the skill gap required for operators.

Conclusion

A plastic pelletizer is more than just a chopper; it is a precision instrument that dictates the value of your recycled product. Whether you are processing industrial scrap or post-consumer waste, the quality of your machinery directly correlates to the quality of your pellets.

By choosing Energycle, you aren't just buying a machine; you are investing in a process that guarantees efficiency, durability, and a higher ROI.

Ready to upgrade your recycling line?

Contact the Energycle team today to discuss which pelletizing system fits your production goals.

https://www.energycle.com/plastic-pelletizers/

Turn Bulky Pipe Waste into Profit with Specialized Shredding Technology

In the plastic recycling industry, few materials pose a challenge quite like plastic pipes. Whether it’s thick-walled HDPE water pipes, long PVC profiles, or surplus extruder tubes, these materials are bulky, tough, and notoriously difficult to process with standard equipment.

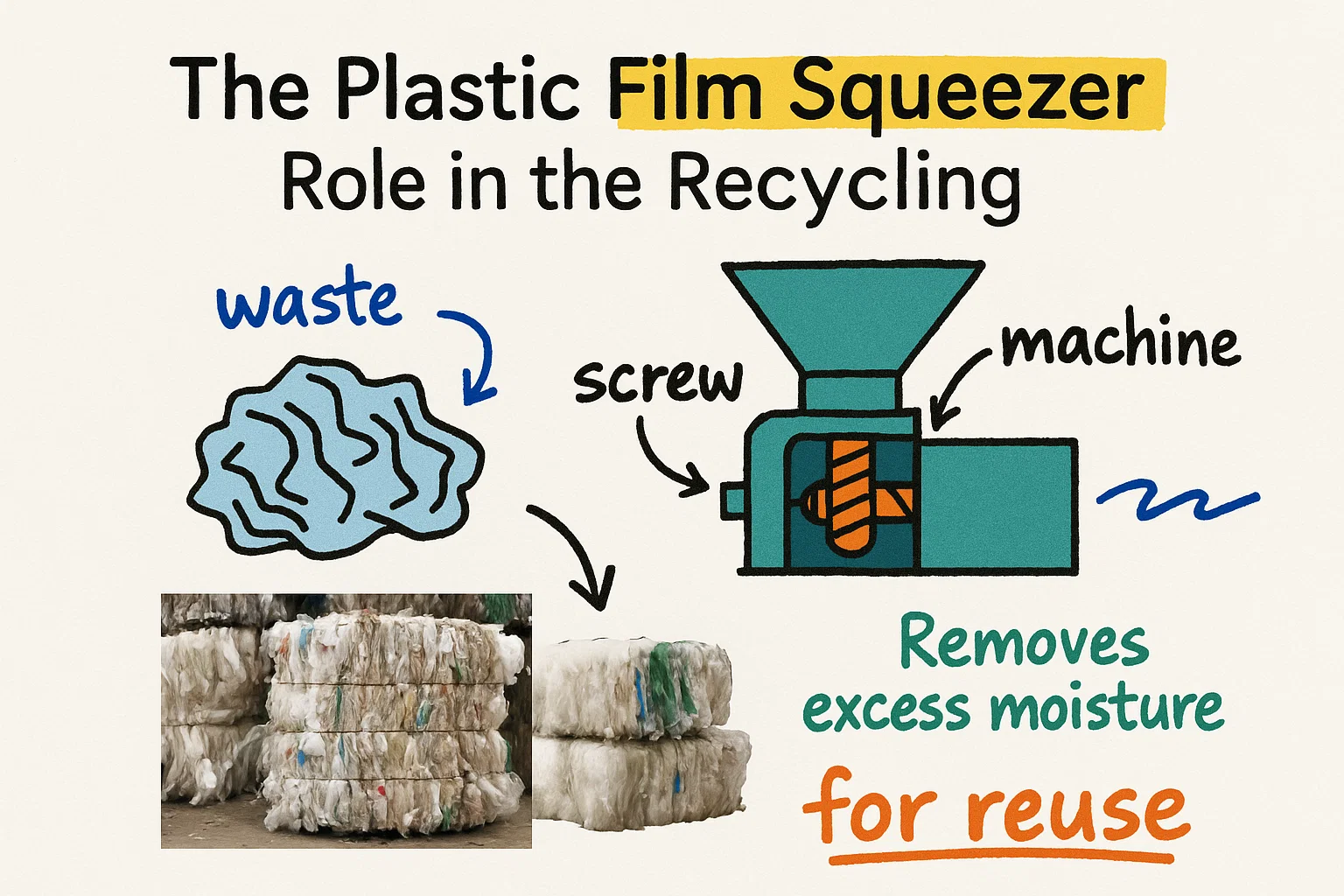

As plastic waste continues to challenge manufacturers worldwide, finding efficient and cost-effective recycling solutions has become critical. At Energycle, we've engineered the Plastic Film Squeezer to address one of the most persistent problems in plastic recycling: effectively processing wet, contaminated plastic films while maximizing energy efficiency and throughput.