Recycling lines rarely fail because the core machine can’t melt or cut plastic. They fail because the plant layout creates bottlenecks: poor material flow, unsafe loading zones, no buffer capacity, or auxiliary systems that don’t match the feedstock.

This guide explains how to think about custom layouts and optional devices in a practical, operations-first way.

Quick Takeaways

- Layout drives labor, safety, and uptime—not only footprint.

- Separate “dirty” receiving/sorting from “clean” product handling when possible.

- Add buffers where production and packing do not run at the same cadence.

- Choose optional devices to solve a defined bottleneck, not because they look advanced.

Why Layout Is a “System Design” Problem (Not a CAD Problem)

When a line underperforms, the root cause is often not the shredder or the extruder—it’s how material arrives, moves, and is staged. A layout that supports steady flow reduces: – surges and starvation at the feed throat – forklift conflicts and unsafe traffic patterns – unplanned stops caused by cleaning access and maintenance bottlenecks

If you’re still comparing line types, Energycle’s plastic recycling machines overview can help align terminology across shredding, washing, and pelletizing systems.

1) Layout Planning: Start With Material Flow, Not a Floorplan Sketch

Before selecting an L/U/Z shape, define: – how material arrives (bales, rolls, bins, loose scrap) – where pre-sorting and metal removal happens – how material reaches the line safely (forklift lanes, guarding, staging zones) – where finished product is stored and packed (bags, big bags, silos)

Good layouts reduce forklift conflicts, shorten walking distances, and prevent surges that create downtime.

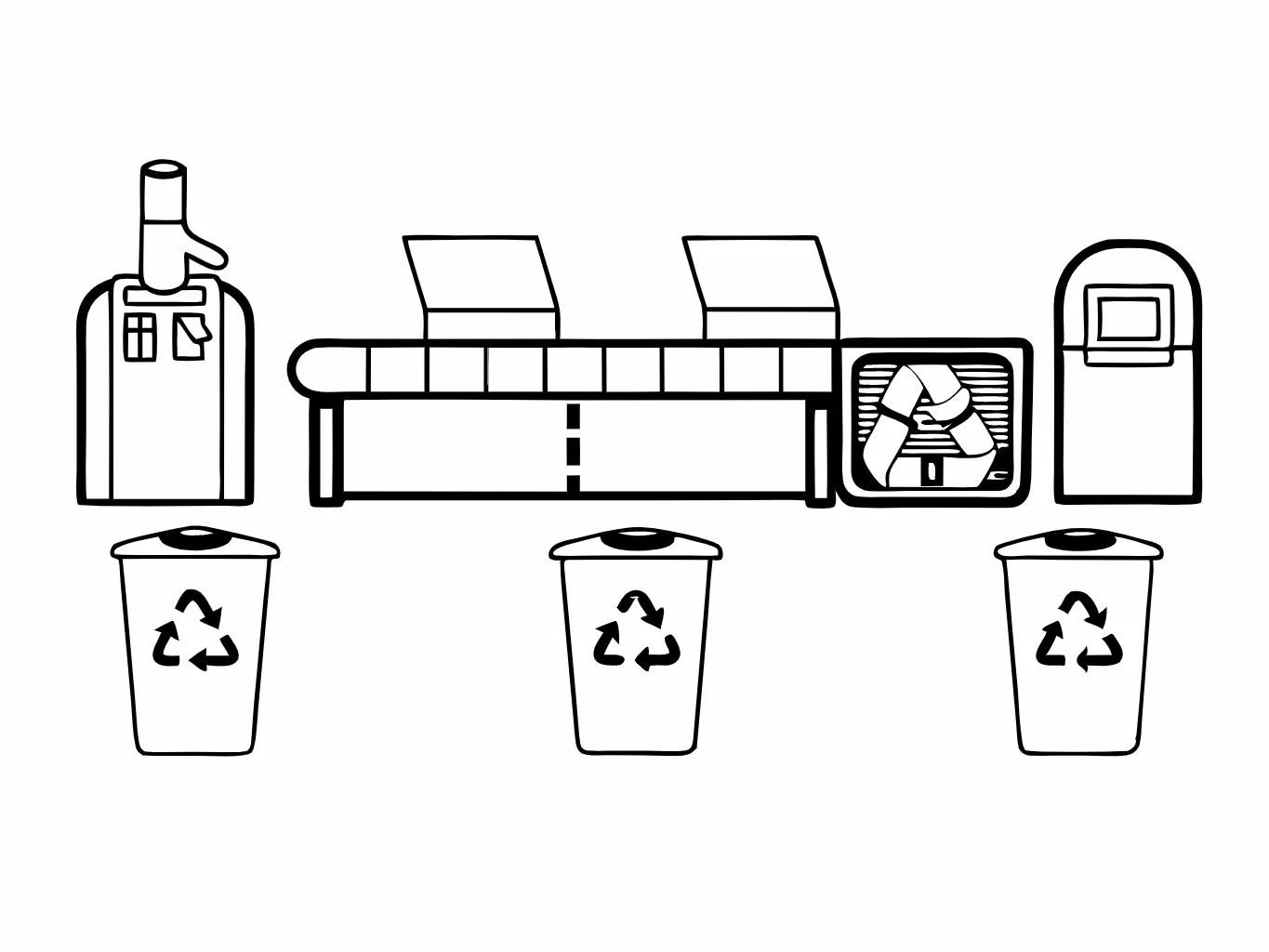

2) Define Zones: Dirty → Transitional → Clean

A simple way to design is to separate the plant into zones:

| Zone | What happens there | Why it matters | Design tips |

|---|---|---|---|

| Dirty receiving | Unload, inspect, and remove obvious contaminants | Prevents contamination and damage from spreading downstream | Plan space for staging, rejects, and safe forklift movement |

| Transitional processing | Size reduction, washing, separation | High noise/dust/water exposure drives maintenance needs | Keep access for cleaning, screens, knives, and lifts |

| Clean output handling | Drying, pelletizing, packing, storage | Quality and customer acceptance depend on cleanliness | Keep traffic controlled; avoid cross-contamination from inbound scrap |

3) Common Layout Patterns (When They Make Sense)

L-shaped layouts

Often used when the building forces a corner turn or when you want separation between dirty receiving and clean packaging zones.

U-shaped layouts

Often used to keep operator stations closer together and simplify supervision, especially when space constraints prevent a straight-through line.

Z-shaped layouts

Often used to route around fixed obstacles (columns, existing equipment) while keeping maintenance access points reachable.

The “right” shape depends on your material handling and safety constraints, not on a universal rule.

4) Optional Devices That Often Improve Real-World Efficiency

A) Controlled feeding and anti-bridging devices

Useful when material is light, irregular, or tends to wrap (film, woven material, flakes with high fines).

B) Metal detection and removal

Used to protect downstream cutting systems and extrusion filtration.

Typical tools include magnets, metal detectors, and guarded inspection points—chosen based on the contamination risk of your stream.

C) Buffer storage (bins and silos)

Buffers decouple upstream and downstream steps. They help when: – receiving/feeding is intermittent – packaging is batch-based – the line must run steadily for quality reasons

D) Filtration upgrades for pelletizing

If your line pelletizes, filtration strategy affects stop frequency and output stability. Selection depends on contamination window, throughput, and maintenance model.

Energycle configures pelletizing lines and filtration packages on its plastic pelletizer machines page.

5) A Simple Bottleneck Map (Use This Before Buying Options)

Optional devices are worth buying when they remove a measurable bottleneck. This table helps you map symptoms to layout or auxiliary equipment changes.

| Symptom | Likely root cause | Layout / option that usually helps |

|---|---|---|

| Frequent extruder starvation or surging | Unstable feeding, no buffer, poor staging | Buffer bin, controlled feeder, better receiving staging |

| Screen changes dominate downtime | Filtration undersized for contamination load | Filtration strategy upgrade, clearer inbound specs, better upstream separation |

| Too much labor in material movement | Poor conveyor routing and forklift conflicts | Conveyor re-route, defined traffic lanes, better product storage placement |

| Cross-contamination in finished product | Dirty and clean zones overlap | Zoning and physical separation; dedicated routes for finished product |

6) Utilities, Maintenance Access, and Safety (Where Layout Pays Back)

Layout decisions also lock in utility runs and maintenance access. If you design for “today’s demo,” you often pay later in downtime.

| Utility / Constraint | What to Plan | Why It Protects Efficiency |

|---|---|---|

| Power and panel access | Clear cable routes, safe service access, spare capacity for options | Retrofits and troubleshooting are faster when the electrical layout is accessible. |

| Water loop and drainage | Short, cleanable drain runs and space for filtration/sludge handling | Backups and dirty water degrade wash quality and create repeated stops. |

| Ventilation and dust/fines control | Defined collection points and clean-out access | Fines buildup creates quality drift and maintenance events. |

| Maintenance clearances | Knife/screen access, lifting paths, and safe lockout zones | When service is slow or unsafe, operators delay it until failure. |

7) What to Provide for a Layout Proposal

To get a useful layout (not a generic drawing), prepare: – a building sketch with columns, doors, ceiling height, and crane limits (if any) – power availability, compressed air, and water/wastewater constraints – your daily material handling method and staffing plan – target product packaging method and storage constraints

Energycle can help turn those inputs into a plant layout and complete line configuration via its contact page.

FAQ (Real Procurement Questions)

How do I know whether I need a buffer bin or silo?

You need a buffer when upstream and downstream steps run at different rhythms. Receiving and feeding are often intermittent, while extrusion and pelletizing usually prefer steady flow for stable melt pressure and consistent output. Packaging can also be batch-based (bag changes, pallet changes), which can force stops if there’s no intermediate storage. A buffer decouples those steps so the main process can run steadily. Ask your team to map where stops happen today (feeding, screen changes, packaging, maintenance), then size buffer capacity to cover the most common interruption window.

Should I prioritize a straight line layout over an L/U/Z layout?

Prioritize material flow and maintenance access, not the shape. Straight lines can be simple, but they can create dirty-to-clean crossovers if the building forces awkward traffic. L- and U-shaped layouts can separate receiving from packing and keep operators closer to critical stations. The right choice depends on how material arrives, how finished product ships, where forklifts must travel, and where you need access for knife changes, screen changes, and cleaning. Ask the supplier to show service access clearances and lifting points on the layout drawing, not just a footprint.

What optional devices typically pay back fastest?

The ones that remove downtime or reduce labor in a repeatable way: controlled feeding for unstable materials, magnets/metal removal for scrap with fasteners, and buffer storage when packaging causes stops. Filtration upgrades can also pay back quickly when contamination causes frequent screen changes and restart scrap. The key is to tie the option to a measurable problem: hours of downtime per week, labor hours per shift, or rejected bales/pellet lots. If the supplier can’t connect the option to a defined bottleneck, treat it as a “nice to have,” not a requirement.

How do I write a layout RFQ so I don’t get a generic drawing?

Send the building constraints (columns, doors, ceiling height, crane limits), utility limits (power, air, water/wastewater), and your operating model (shifts, staffing, packaging method, forklift traffic). Also include photos of inbound material and a sketch of how it arrives (bales, bags, loose). Then require a zone plan (dirty/transitional/clean), a material flow diagram, and a maintenance access plan. A layout that doesn’t show service access for knives, screens, and cleaning is incomplete. The drawing should support operations, not just fit in the building.

Are there safety standards I should reference in a recycling line layout?

Yes—especially for guarding, access control, and maintenance procedures. For U.S. facilities, OSHA guidance on machine guarding and lockout/tagout is a useful baseline when you define requirements for interlocks, safe access, and maintenance routines. The layout should make safe maintenance possible by design: clear access, lifting points, and lockout points that don’t require unsafe workarounds. Also require a documented procedure for jam clearing and cleaning so operators don’t improvise around guards. (OSHA: machine guarding and 29 CFR 1910.147 lockout/tagout)