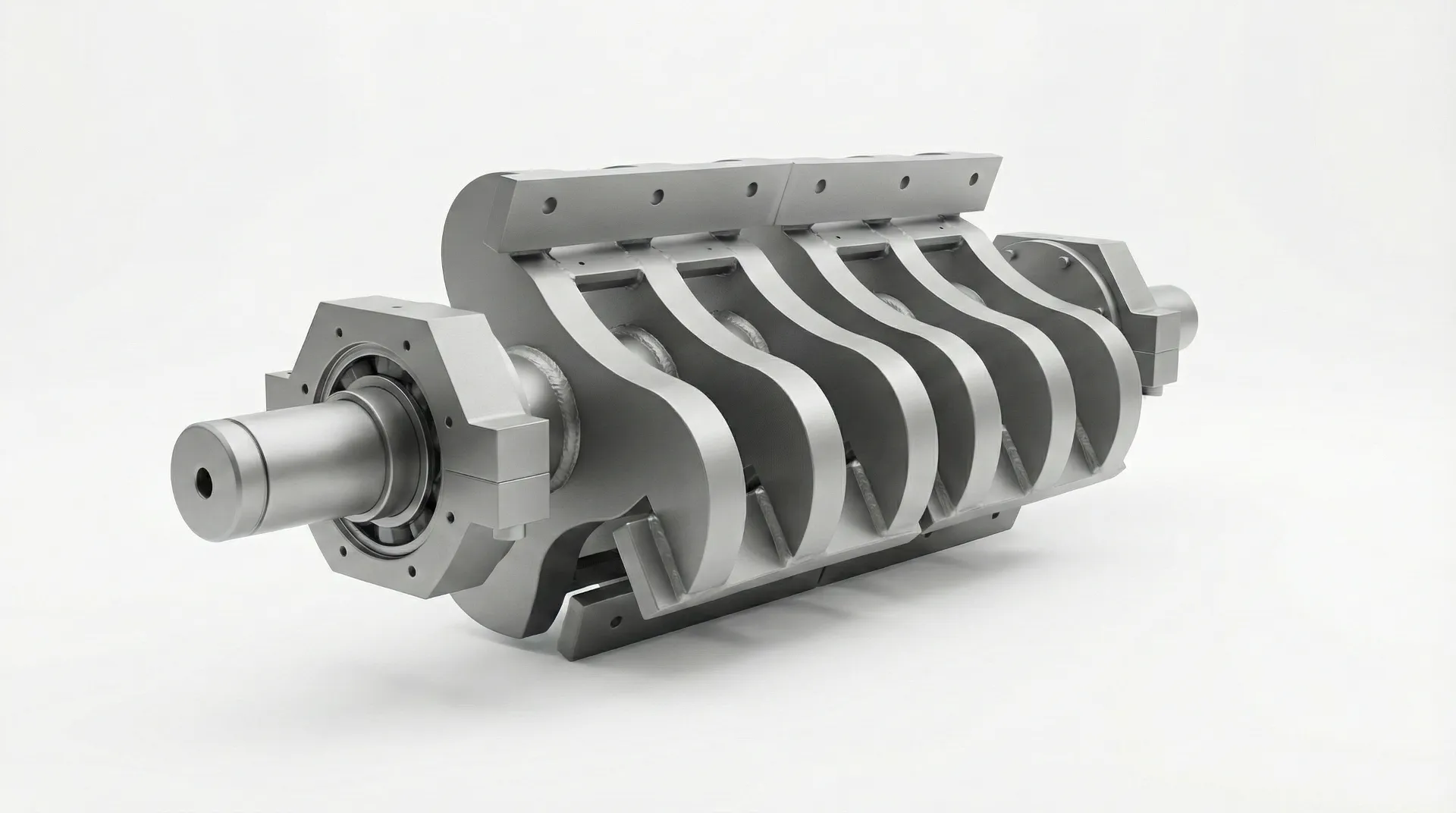

Integrated Shredder-Granulator Machine

Transform bulky waste into uniform, reusable granules in a single pass. Our all-in-one system combines a high-torque shredder and a high-speed granulator to maximize efficiency and save valuable floor space.

The All-in-One Advantage

Forget complex, multi-machine setups. Our integrated shredder-granulator streamlines your workflow, reduces costs, and delivers consistently high-quality output.

Save Space & Reduce Costs

Combining two machines into one compact unit reduces your equipment footprint by up to 50%. This lowers initial investment, simplifies installation, and cuts ongoing energy and maintenance costs.

Automated, One-Person Operation

Experience seamless, continuous material flow from shredding to granulation. An intelligent PLC control system with a user-friendly touchscreen allows for efficient, one-person operation.

Robust & Reliable Performance

Engineered with a heavy-duty frame, wear-resistant alloy steel blades, and premium components to ensure maximum uptime and operator safety in demanding industrial environments.

Two-Stage Recycling in a Single Machine

Our integrated system uses a sequential process to efficiently transform waste.

Stage 1: Shredding

Bulky material enters the high-torque, low-speed shredder for primary size reduction into rough strips.

Stage 2: Granulation

The shredded strips fall directly into the high-speed granulator, where they are ground into fine, uniform regrind.

Ideal Applications

The perfect all-in-one solution for operations that require a consistent, fine-particle output from a variety of waste streams.

Plastics Recycling

Perfect for processing PE, PP, PET, and PVC materials, including bottles, containers, film rolls, purgings, and hard plastic lumps.

E-Waste & Cables

Efficiently liberates metals by granulating plastic components from electronics, wire and cable scrap, and circuit boards.

Wood & Biomass

Reduces wood scraps, offcuts, and green waste into fine chips suitable for animal bedding, boiler fuel, or compost.

Typical Materials We Process

Ideal for dense lumps, purgings, and irregular resin waste that needs reliable size reduction into uniform regrind.

Epoxy Resin Waste

Cured epoxy lumps and cast‑off residues—reduced into uniform granules for easier handling and downstream processing.

Polyurethane (PU) Resin Residues

Drum/bucket bottom leftovers, cured blobs, and resin build‑up—processed into consistent regrind for downstream recycling.

Extruder Die‑Head Purgings

Start‑up scrap, hot‑melt purgings, and die head lumps—shredded then granulated for stable reprocessing.

Injection Molding Purgings

Start‑up purges, sprues, runners, and thick parts—converted into uniform regrind with a controllable particle size.

Thermoforming Skeleton & Offcuts

Sheet skeletons, trims, and edge offcuts—reduced efficiently for closed‑loop reuse.

Hard Plastic Lumps & Purges

Hard-plastic production waste (e.g., PP/PE/ABS/PS) including thick lumps and edge trim—sized to your target screen.

Technical Specifications

| Shredder Motor Power | Ranges from 18.5 kW to 75 kW |

|---|---|

| Granulator Motor Power | Ranges from 15 kW to 55 kW |

| Processing Capacity | 300 kg/hr to 1500 kg/hr (material dependent) |

| Final Particle Size | Typically 5 mm - 15 mm (customizable with screens) |

| Blade Material | High-grade D2 / SKD11 Alloy Steel |

| Control System | Integrated PLC with HMI Touchscreen |

| Safety Features | Emergency stops, rotor lock, overload protection |

Frequently Asked Questions

Is this machine better than having a separate shredder and granulator?

For many applications, yes. The integrated design saves significant floor space, reduces capital investment, lowers energy consumption, and simplifies operation. It's ideal for facilities that need a streamlined, single-pass process to get from bulky waste to fine granules. Separate machines may offer more flexibility for very high-volume or specialized operations.

What materials is this machine best suited for?

This system excels at processing materials that require both initial breaking and fine grinding. It is particularly effective for hard plastics (purgings, lumps), plastic films, E-waste, cables, and wood scrap. It is generally not recommended for shredding heavy steel or highly abrasive materials.

How is maintenance performed on the two cutting chambers?

Our machines are designed with maintenance in mind. Both the shredder and granulator chambers feature easy-access panels, allowing for quick inspection, rotation, or replacement of the cutting blades and screens with minimal downtime.

Warranty & Installation

Get predictable commissioning, operator guidance, and long-term service to keep your shredder‑granulator running at peak performance.

1‑Year Limited Warranty

Coverage for key mechanical components against manufacturing defects (wear parts excluded), helping protect your investment.

Commissioning Support

We provide installation guidance, recommended settings, and operator training for a smooth start-up and stable daily operation.

Ready to Revolutionize Your Recycling Workflow?

Contact our specialists today to discuss your material requirements. We will provide a personalized consultation, a detailed quote, and information on how our all-in-one shredder-granulator can transform your operation.