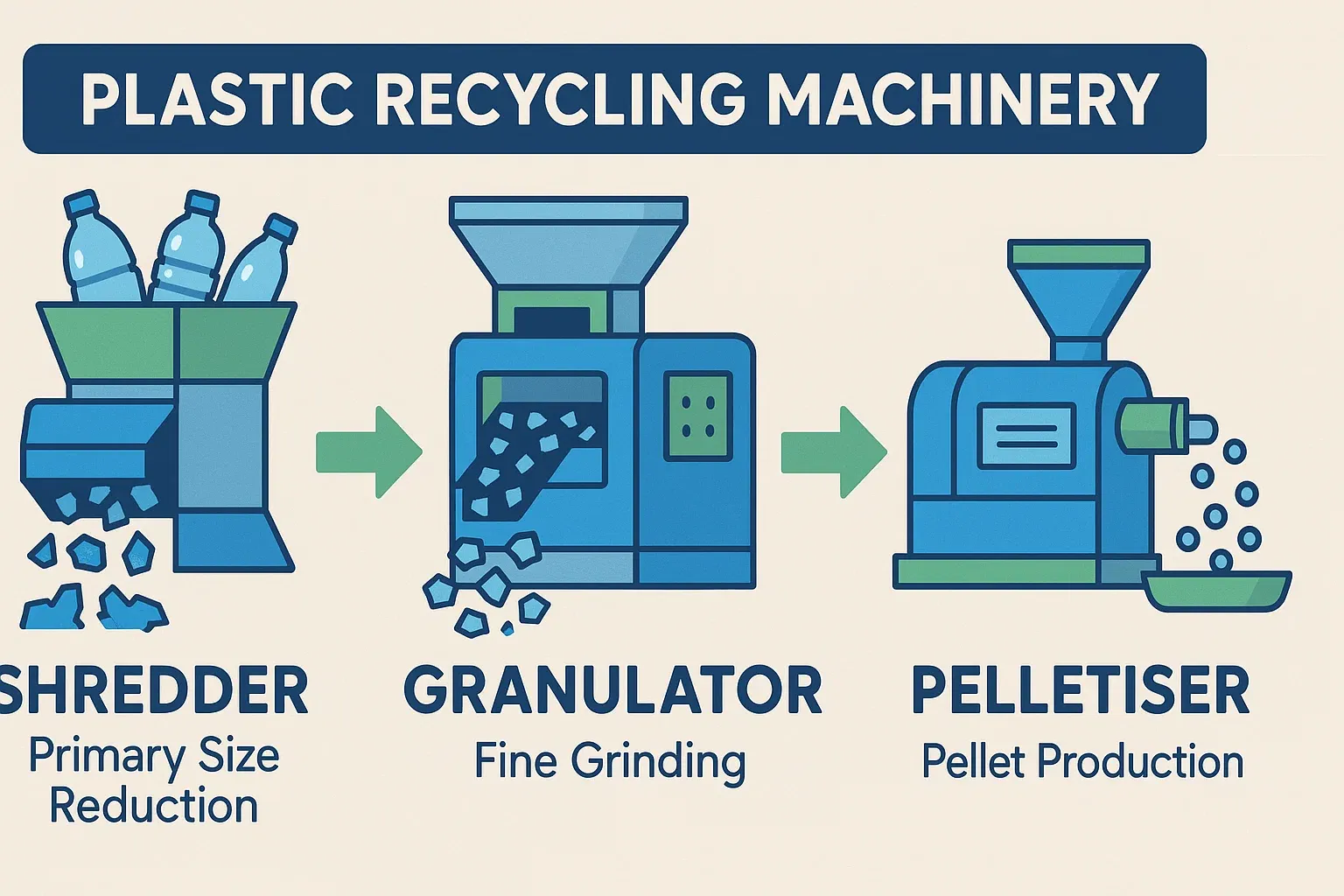

A recycling line is a cascade of size reduction. Attempting to granulate a whole pipe will destroy the machine. Attempting to extrude dirty flake will block the screen. This guide explains the engineering hierarchy of Primary, Secondary, and Tertiary processing.

Related equipment: integrated shredder-granulator machine, single shaft shredder.

1. Primary Reduction: The Shredder (20:1 Ratio)

- Input: Everything (Bales, Purging, Pipes, Pallets).

- Mechanism: Shear. Low Speed (60-80 RPM) + High Torque.

- Role: To create a manageable “flowable” chip (40-60mm).

- Why: You cannot feed a 1-meter pipe into a granulator. The shredder acts as the “Pre-Conditioner.”

- Vulnerability: Tramp Metal. (Requires Overband Magnet).

2. Secondary Reduction: The Granulator (5:1 Ratio)

- Input: Shredded Chips (Clean or Dirty).

- Mechanism: Scissor Cut. High Speed (400-600 RPM).

- Role: To create a uniform “Regrind” (8-12mm).

- Why: Washing lines require small particles to clean effectively (friction). Extruders need uniform bulk density to melt consistently.

- Vulnerability: Heavy shocks. The high inertia rotor will explode if it hits a solid bolt.

3. Tertiary Processing: The Pelletizer (1:1 Ratio)

- Input: Clean, Dry Regrind/Flake.

- Mechanism: Plastification (Melting + Filtration + Degassing).

- Role: To create a virgin-like “Pellet” (3mm).

- Why:

- Filtration: It is the only step that removes non-melting contaminants (wood, paper, aluminum) via a Laser Filter.

- Degassing: Vacuum venting removes volatiles (inks, moisture) that cause bubbles.

- Flowability: Injection molders cannot run light fluffy regrind; they need dense pellets.

Comparison Matrix

| Feature | Shredder | Granulator | Pelletizer |

|---|---|---|---|

| Speed | Slow (80 RPM) | Fast (500 RPM) | Variable (Screw) |

| Torque | Massive | Moderate | Moderate |

| Noise | 80-85 dB | 95-100 dB | 80 dB |

| Output | 50mm Chips | 10mm Flake | 3mm Pellet |

| Maintenance | Low (Rotate knives) | High (Sharpen daily) | Medium (Screens) |

System Design Rules

Rule of 40mm

Never feed material $>40mm$ into a standard granulator. It wears the blades exponentially faster. Let the shredder do the heavy lifting.

The Bulk Density Curve

- Baled Film: 200 kg/m³.

- Shredded Film: 300 kg/m³.

- Densified/Granulated Film: 400 kg/m³.

- Pelletized Film: 800 kg/m³.

Increasing bulk density reduces storage and transport costs.

References

[1] “Size Reduction of Plastics,” Society of Plastics Engineers. Size Reduction of Plastics

[2] “Extrusion Processing Guide,” Battenfeld-Cincinnati. Extrusion Processing Guide