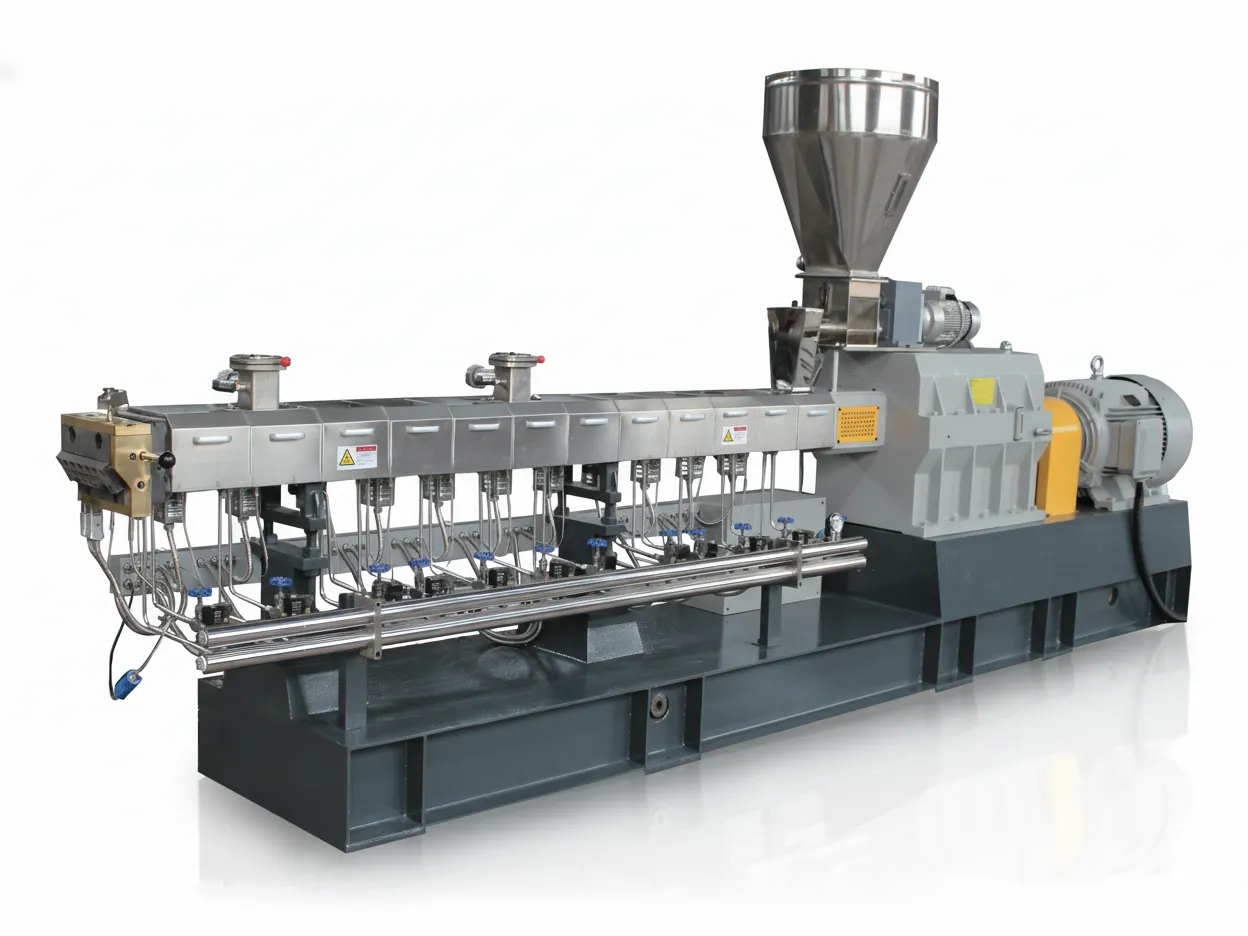

Twin-Screw Compounding & Extrusion Pelletizing Line

Purpose-built for mixing, compounding, devolatilization, and stable extrusion—ideal for masterbatch, filled compounds, polymer blends, and high-value recycled compounds.

Request a QuoteDesigned for Compounding, Not Just Extrusion

Unlike a general-purpose twin-screw extruder that primarily pushes a pre-compounded melt, this line is engineered to disperse fillers and additives evenly, remove volatiles with venting/vacuum, and deliver consistent pellet quality with integrated filtration and pelletizing.

Compounding-Grade Advantages

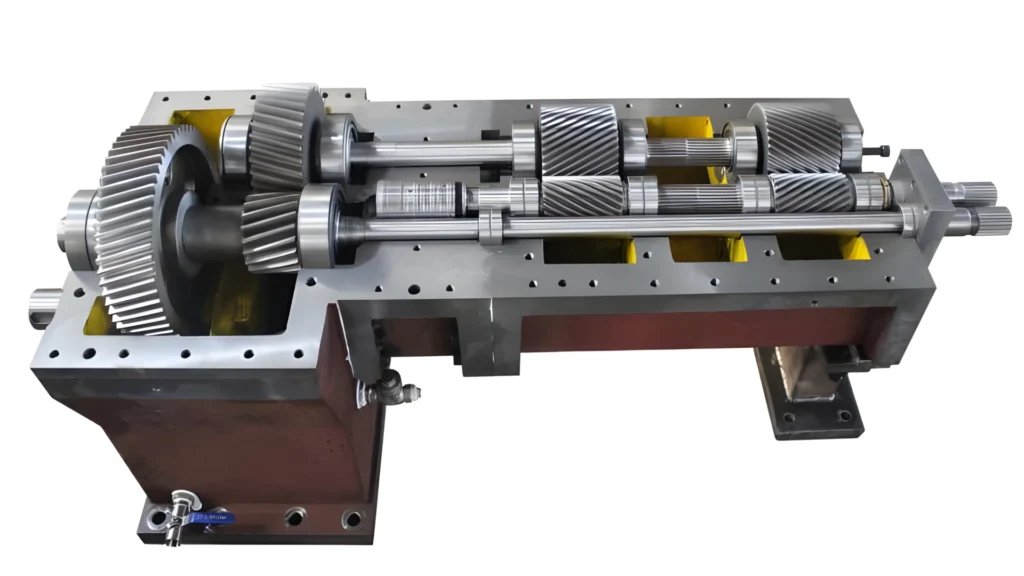

High-Intensity Mixing

Optimized screw elements deliver strong dispersive and distributive mixing for stable compound properties.

Precision Feeding

Supports gravimetric/volumetric feeders, side-feeding, and tailored dosing for fillers, fibers, and additives.

Devolatilization Control

Venting and vacuum options remove moisture and volatiles for cleaner pellets and fewer defects.

Integrated Filtration & Pelletizing

Hydraulic screen changer and pelletizing choices (strand or water-ring) stabilize quality and output.

How It Differs from a Standard Twin-Screw Extruder

Best for simple extrusion

Often used to melt and convey materials that are already well-prepared or pre-compounded.

- Limited dispersion at high filler/additive loading

- Fewer dedicated compounding zones (venting, vacuum, side feeding)

- Downstream equipment may be external or non-integrated

- Higher risk of batch-to-batch variation for complex recipes

Built for mixing + compounding + extrusion

Designed to turn resin + fillers + additives into a consistent compound, then pelletize with stable quality control.

- Configurable screw/barrel modules for dispersive & distributive mixing

- Feeder options for powders, fibers, liquids, and side feeding

- Venting/vacuum to remove volatiles and improve pellet appearance

- Integrated filtration + pelletizing for cleaner, uniform pellets

The Mixing–Compounding–Extrusion Workflow

- Feeding & Dosing: Resin and additives are accurately metered (main feeder + side feeder as needed).

- Intensive Mixing: Screw elements disperse fillers/pigments and distribute additives evenly through the melt.

- Venting / Vacuum: Moisture and volatiles are removed to improve stability and reduce bubbles/odor.

- Melt Filtration: A hydraulic screen changer captures contaminants for a clean, stable melt stream.

- Pelletizing: Choose strand or water-ring pelletizing based on polymer and downstream requirements.

- Cooling & Handling: Pellets are cooled, dried (if needed), and conveyed for storage or packaging.

High-Value Compounding Applications

Masterbatch Production

High-concentration color/additive/filler masterbatch with consistent dispersion and repeatable quality.

Filled & Reinforced Compounds

Optimized for minerals (CaCO₃, talc) and fiber reinforcement with stable throughput and melt control.

Recycled Compounds

Improves consistency of recycled streams with devolatilization and filtration for cleaner pellets.

Reactive / Functional Compounding

Supports controlled mixing zones for specialty formulations and functional additives.

Main Technical Parameters

| Line | Extruder | Screw Diameter (mm) | Screw Speed (rpm) | Motor Power (kW) | Capacity (kg/h) |

|---|---|---|---|---|---|

| GTS52/120 | GTE52 | 51.4 | 600 | 55–75 | 180–260 |

| SJ120 | 120 | 85 | |||

| GTS65/150 | GTE65 | 62.4 | 600 | 90–110 | 260–350 |

| SJ150 | 150 | 85 | |||

| GTS75/180 | GTE75 | 71 | 600 | 132–160 | 450–550 |

| SJ180 | 180 | 85 | |||

| GTS95/200 | GTE95 | 93 | 600 | 185–200 | 650–750 |

| SJ200 | 200 | 85 |

*Specifications may vary based on formulation and configuration. Contact us for a matched solution.

Machine Showcase

Watch It in Action

A quick look at the compounding and pelletizing workflow.

Warranty & Installation

1-Year Limited Warranty

All of our recycling and compounding systems include a comprehensive one-year limited warranty.

Process Support & Customization

We provide screw configuration guidance, installation support, and after-sales service to match your formulation and output targets.

Frequently Asked Questions

What makes this compounding line different from a normal twin-screw extruder?

This system is configured around mixing, devolatilization, filtration, and pelletizing—so it can reliably turn resin + fillers/additives into a consistent compound. A standard extruder is often focused on simple extrusion of already-prepared material.

Can you support high filler or glass-fiber formulations?

Yes. With the right feeders and screw elements, the line can handle mineral-filled and reinforced compounds. Capacity and achievable loading depend on formulation, particle size, and dosing stability—share your recipe for a recommended configuration.

How do I choose strand pelletizing vs. water-ring pelletizing?

Strand pelletizing is robust and widely used for many compounds. Water-ring pelletizing is compact and efficient for stable melt flows. We recommend based on polymer type, throughput, and pellet quality requirements.

Do you provide screw configuration and commissioning support?

Yes. We can recommend screw/barrel layouts and provide installation guidance, start-up support, and maintenance advice to help you reach stable output quickly.

What inputs do you need to size the line correctly?

Please share polymer type(s), filler/additive percentages, target capacity (kg/h), moisture/contamination level, and desired pelletizing method. We’ll match the extruder size, feeders, filtration, and downstream equipment.

Get a Quote for Your Compounding Line

Tell us your formulation and target capacity—our team will recommend the right feeders, screw configuration, filtration, and pelletizing setup.