Expanded Polystyrene (EPS), widely used for packaging, insulation, and disposable food containers, is notoriously challenging to recycle due to its lightweight and bulky nature. However, modern recycling machinery like EPS recycling machines provides efficient solutions for handling and repurposing EPS waste. This article delves into the workflows of the two primary types of EPS recycling machines—cold pressing and hot melting—to help you choose the most suitable equipment for your recycling operations.

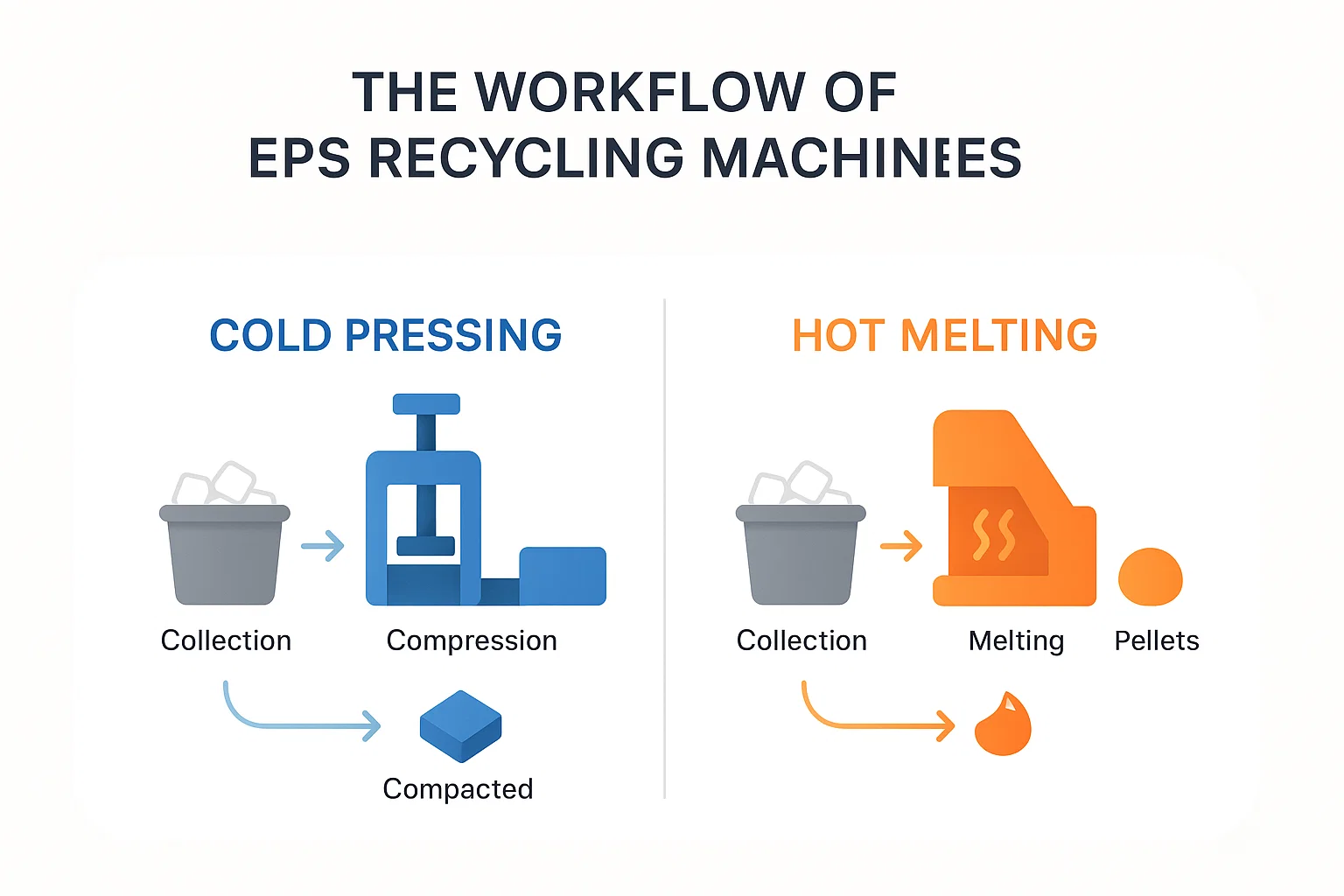

Cold Pressing EPS Recycling Machine Workflow

Cold pressing machines, also known as EPS densifiers, compact EPS waste mechanically without applying heat, significantly reducing its volume.

- Collection and Sorting

The initial stage involves collecting EPS waste and ensuring that contaminants such as tape, labels, and dirt are removed. - Shredding

The clean EPS waste is fed into a shredder, breaking it down into smaller, manageable pieces. - Compression

The shredded EPS material is then fed into the cold pressing chamber, where it is mechanically compressed under high pressure. This reduces its volume by up to 50:1. - Extrusion into Blocks

The compressed EPS is extruded into dense, solid blocks or logs, ready for efficient transportation and storage.

Advantages:

- Lower energy consumption.

- No heat-related emissions.

- Suitable for operations seeking simplicity and cost-effectiveness.

For detailed information about cold pressing machinery, explore our EPS Foam Cold Press Machine page.

Hot Melting EPS Recycling Machine Workflow

Hot melting machines operate by melting EPS materials into a compact, reusable form, significantly increasing the recycling efficiency.

- Collection and Pre-processing

Similar to cold pressing, EPS waste is collected and cleaned to remove contaminants. - Feeding and Crushing

EPS materials are introduced into the machine’s hopper and processed through an integrated crusher, reducing them into smaller fragments. - Melting Process

The crushed EPS enters a heating chamber where it is melted at temperatures between 140°C and 200°C, turning it into a liquid state. - Extrusion and Cooling

The molten EPS is extruded through a nozzle, forming dense ingots or blocks as it cools and solidifies.

Advantages:

- High reduction ratio (up to 90:1).

- Produces uniform, dense ingots suitable for recycling into new products.

- Efficient handling of large volumes of EPS waste.

Visit our detailed EPS Foam Melting Machine guide to understand more about hot melting processes.

Comparative Analysis: Cold Pressing vs Hot Melting

Choosing between cold pressing and hot melting machines depends on several operational factors:

| Feature | Cold Pressing | Hot Melting |

|---|---|---|

| Volume Reduction Ratio | Moderate (up to 50:1) | High (up to 90:1) |

| Energy Consumption | Lower | Higher |

| Quality of End Product | Solid compressed blocks | Uniform ingots suitable for reuse |

| Environmental Impact | Minimal heat emissions | Higher due to heating process |

Choosing the Right EPS Recycling Machine for Your Business

Consider your operational scale, available budget, and recycling objectives when selecting your EPS recycling machinery. Cold pressing offers simplicity and lower operating costs, ideal for smaller businesses or operations with moderate EPS waste. In contrast, hot melting suits businesses requiring higher density outputs and greater recycling efficiency.

Conclusion

Energycle’s EPS recycling machines, both cold pressing and hot melting, provide sustainable, practical solutions tailored to your industrial recycling needs. By investing in the appropriate equipment, businesses can achieve significant environmental and economic benefits while reinforcing their commitment to sustainability.

To discuss the most suitable EPS recycling solutions tailored to your requirements, contact our expert team today!