The ubiquitous plastic bag, a staple of convenience, presents a significant environmental challenge. However, within this challenge lies a substantial opportunity for innovative and profitable recycling. For industrial recycling professionals and equipment buyers, understanding the end-of-life potential of plastic bags is crucial for tapping into a growing market. At Energycle, we specialise in providing robust plastic recycling machinery that transforms this common waste stream into valuable new products, driving the circular economy forward.

Plastic bags, predominantly made from polyethylene (PE), are 100% recyclable. With the right technology, they can be reprocessed and given a new lease of life, diverting vast quantities from landfill and our oceans. The UK market for recycled plastics is on a growth trajectory, projected to reach a value of £3 billion by 2035, spurred by consumer demand for sustainable products and government initiatives like the Plastic Packaging Tax. This creates a fertile ground for businesses equipped to handle this material.

From Waste to Wonder: The New Life of a Plastic Bag

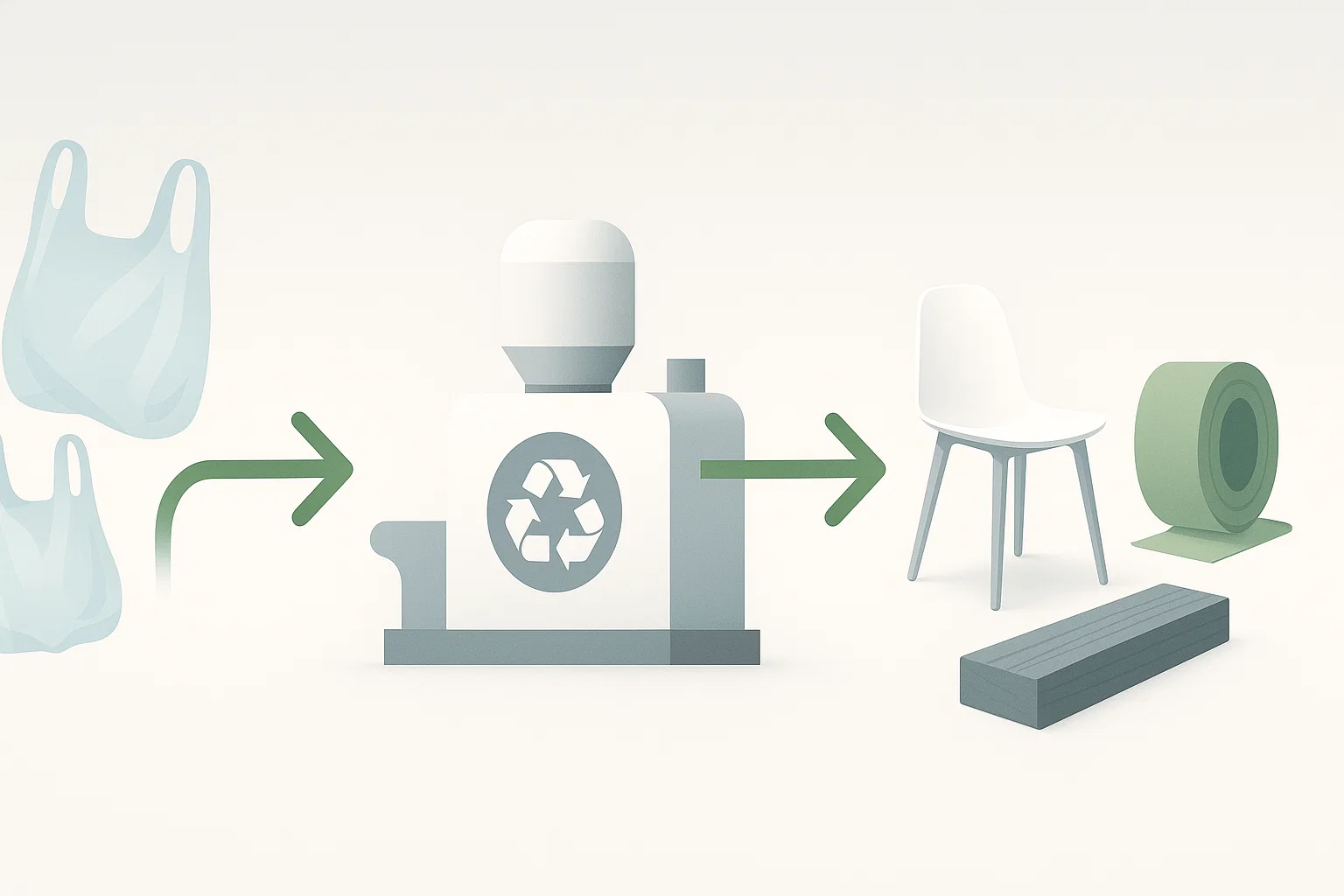

The applications for recycled plastic bags are diverse and expanding, catering to both industrial and consumer markets. Once processed through a dedicated plastic recycling machine, the resulting plastic pellets or granules become a versatile raw material for a host of new products.

Industrial and Construction Applications:

- New Plastic Bags and Film: A significant portion of recycled plastic bags is used to manufacture new ones, creating a closed-loop system. This includes everything from bin liners and agricultural film to industrial packaging.

- Composite Lumber: Recycled plastic is blended with wood fibres to create durable, low-maintenance composite lumber. This material is ideal for decking, fencing, and outdoor furniture, offering a sustainable alternative to traditional timber.

- Construction Materials: The versatility of recycled plastic allows it to be incorporated into various building materials such as pipes, flooring, and insulation, contributing to greener construction practices.

- Waterproofing Membranes: The inherent water-resistant properties of polyethylene make it an excellent material for manufacturing waterproofing membranes used in construction and agriculture.

Consumer and Innovative Products:

- Fashion and Textiles: In a fascinating display of innovation, plastic bags and other films are being transformed into fabrics for clothing and accessories. Scientists have developed methods to turn polythene into comfortable, wearable textiles suitable for sportswear and even high-end fashion. UK-based companies are already creating swimwear and jackets from recycled plastics.

- Furniture: From stylish chairs and tables to practical park benches, recycled plastic is being moulded into a wide array of modern furniture.

- Automotive Parts: The automotive industry is increasingly using recycled plastics for interior components, dashboards, and bumpers to enhance sustainability.

- Reusable Bags: Many eco-conscious brands are producing colourful and durable reusable shopping bags and backpacks from recycled plastic, directly combating the single-use problem.

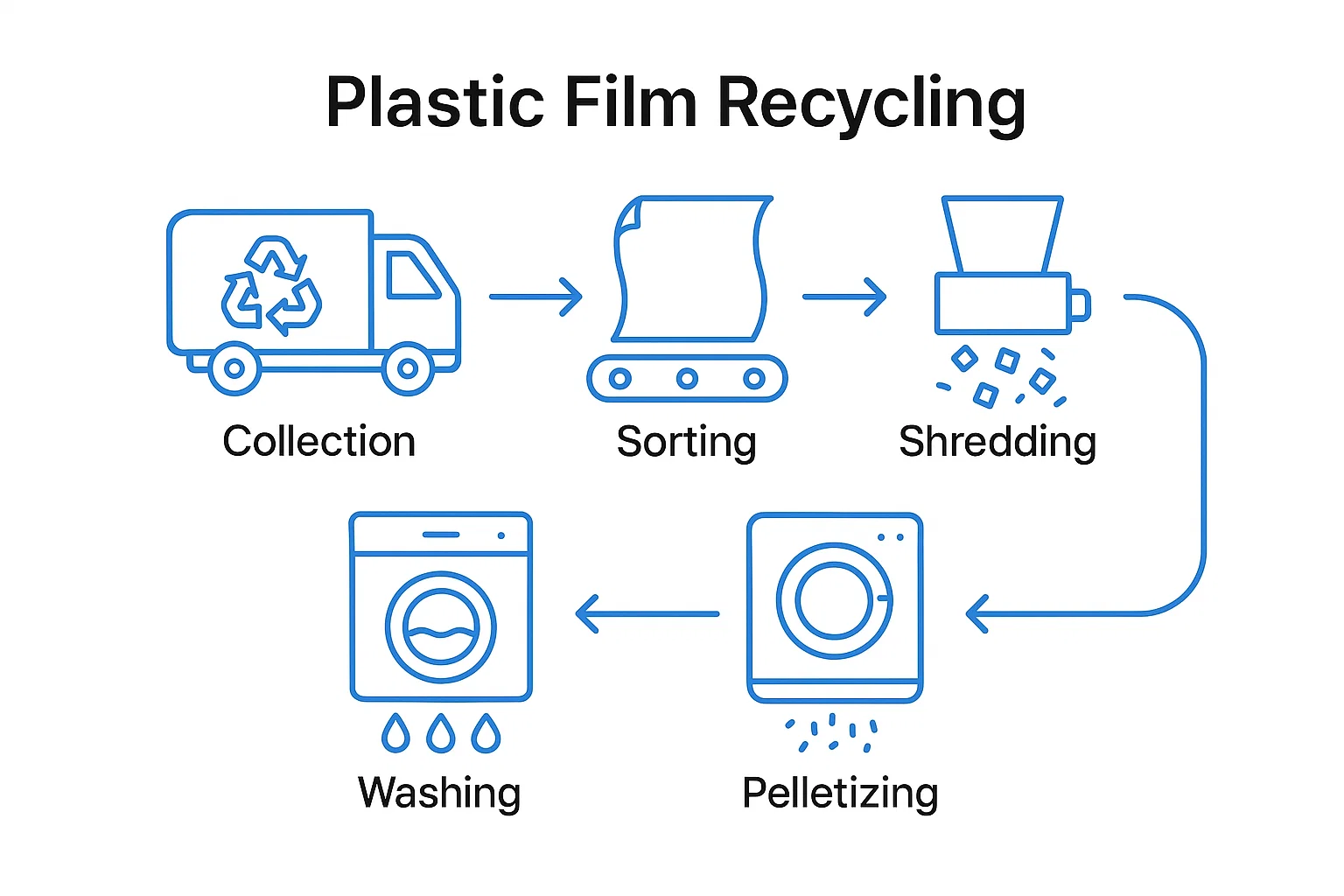

The Journey of a Plastic Bag: A Step-by-Step Recycling Process

Transforming a used plastic bag into a valuable commodity involves a multi-stage process, powered by a series of specialised plastic recycling machines. Understanding this workflow is key for any industrial recycling operation.

- Collection and Sorting: The process begins with the collection of plastic bags. At a materials recovery facility (MRF), they are sorted from other recyclables. As plastic films can entangle standard sorting machinery, they often require separate collection streams or specialised sorting solutions.

- Shredding and Grinding: Once sorted, the plastic bags are fed into industrial shredders or granulators. These powerful machines break down the bulky, lightweight film into smaller, more manageable flakes or granules.

- Washing and Cleaning: The plastic flakes then enter a washing line to remove contaminants such as dirt, labels, and food residue. A hot wash may be used for heavily soiled films to ensure a high-quality end product.

- Drying: After washing, the material is thoroughly dried. This is a critical step as excess moisture can affect the quality of the final plastic pellets.

- Extrusion and Pelletizing: The clean, dry plastic flakes are fed into an extruder. The extruder melts the plastic at a controlled temperature and pushes it through a die. As the molten plastic exits the die, it is cut into small, uniform pellets by a pelletizer. These pellets are the final product, ready to be sold to manufacturers.

The Machinery Powering the Transformation

The efficiency and profitability of a plastic bag recycling operation hinge on the quality and performance of its machinery. At Energycle, we provide a comprehensive range of plastic recycling machines designed to handle the specific challenges of plastic film.

Key Equipment in a Plastic Film Recycling Line:

- Shredders and Granulators: These are the first step in size reduction. Granulators, in particular, are vital for producing uniform particles ready for extrusion. There are different types to consider, for instance, wet granulators spray water during operation to clean the plastic and reduce friction, extending blade life.

- Washing Lines: A complete washing line will typically include a friction washer and a float-sink tank to effectively separate different types of plastics and remove impurities.

- Extruders: The heart of the recycling process, the extruder melts and homogenises the plastic flakes. The choice of extruder will depend on the type of plastic and the desired output. Key specifications to consider include screw diameter, L/D ratio, and degassing capabilities for printed films.

- Pelletizers: This final stage determines the shape and size of the recycled plastic pellets. Water-ring die-face cutters are commonly used for recycling plastic film.

Success Stories in the UK

The UK is home to a growing number of businesses successfully turning plastic bag waste into valuable resources. For example, the FPF FlexCollect trial is exploring the best ways to collect plastic bags and wrapping at the kerbside, aiming to boost recycling rates. Companies like Jayplas are market leaders in recycling plastic packaging and converting it into high-quality polymers and new packaging products. Furthermore, brands like Kingsmill have successfully trialled bread bags containing 30% post-consumer recycled content, demonstrating the potential for a circular economy for plastic bags. These examples underscore the viability and importance of investing in capable plastic recycling machine technology.

The Energycle Advantage

The journey from a discarded plastic bag to a durable new product is a testament to the power of modern recycling technology. For industrial buyers and recycling professionals, the opportunities within this sector are significant. Investing in the right plastic recycling machine is not just an environmental decision; it is a sound business strategy.

At Energycle, we understand the technical demands of plastic film recycling. We provide high-performance, reliable machinery tailored to your specific needs, from individual units to complete recycling lines. Our expertise ensures you have the right tools to efficiently process plastic bags and unlock their full economic potential. Contact us today to learn how our solutions can empower your recycling operations and contribute to a more sustainable future.