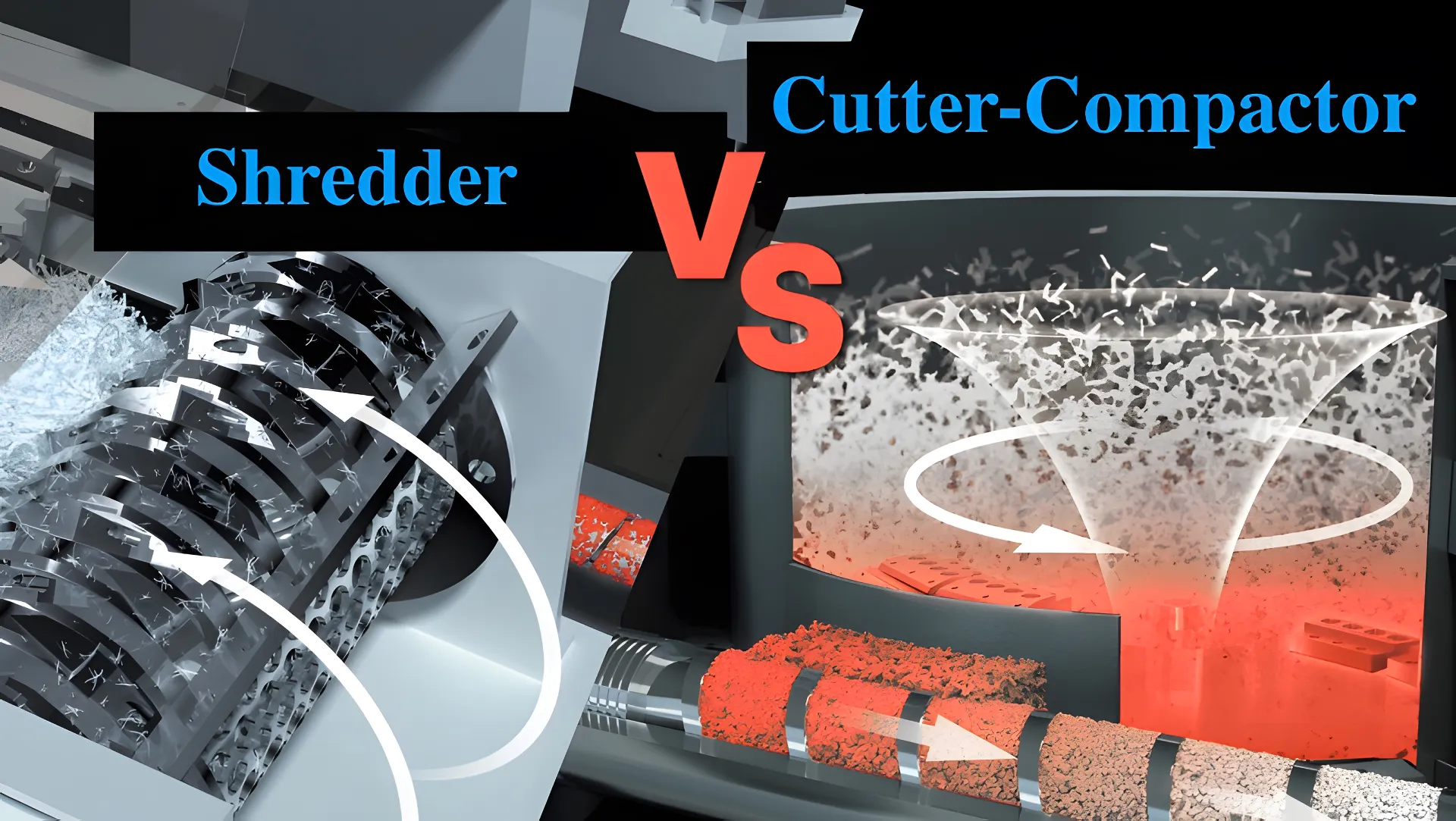

Understanding cutter compactors and shredders in plastic recycling

Cutter-Compactor vs. Shredder decisions usually come down to one question. Are you processing soft film that needs densifying and stable feeding. Or bulky rigid scrap that needs aggressive size reduction.

Both machines support extrusion and pelletizing. They do it in different ways. This guide explains how each machine works, what materials each handles best, and how to choose the right layout for your recycling line.

What a cutter compactor does

A cutter compactor cuts and densifies light and flexible plastics into a uniform, hot, fluffy regrind that feeds an extruder consistently.

Most cutter compactor designs use two cutting elements.

- Stationary knives mounted in the cutting chamber that provide a fixed shearing edge.

- Rotating knives on a rotor that cut and mix the material to keep it moving and evenly processed.

Because the material is continuously mixed, the output is more homogeneous than standard shredding. This matters for film and light packaging. Film tends to bridge, wrap, and feed unevenly. Densification reduces bulk density swings and helps the extruder pull material at a steady rate.

If your film stream is contaminated, plan the cleaning stage before extrusion. A high-speed friction washer can remove dirt, paper, and stubborn residue so the extruder sees a more consistent feed (Lavadora de tornillo de fricción).

Best fit materials: PE film and bags (HDPE LDPE LLDPE) and PP film or raffia that is clean and reasonably consistent.

What a shredder does

A shredder is built for heavy duty size reduction. It turns large, rigid, or thick plastic scrap into manageable pieces for washing, separation, or extrusion.

Typical industrial shredders rely on controlled feeding toward a rotor with robust cutting tools. The goal is simple. Break bulky scrap into a size that downstream equipment can handle without overload.

Shredders do not mix or densify. They primarily reduce size. If your process requires stable feeding into an extruder, you usually add a feeder, compaction stage, or buffer system after shredding.

Best fit materials: thick HDPE and PP parts, injection molded scrap, purge lumps, pipe, crates, and mixed rigid streams.

Cortadora-Compactadora vs. Shredder: key differences

| Factor | Cortadora-Compactadora | Desfibradora |

|---|---|---|

| Primary job | Cut plus densify to stabilize extrusion feeding | Strong size reduction for bulky or rigid scrap |

| Material handling | Handles light, flexible, low bulk density plastics well | Handles thick, rigid, and heavy pieces well |

| Output behavior | More uniform bulk density, better feeding consistency | More variable bulk density, often needs a controlled feed system |

| Rol típico en una línea | Film recycling and compact pelletizing lines | Rigid recycling, washing lines, pre shredding before granulation |

| Huella | Compact, integrated with extrusion in many designs | Usually larger, depends on rotor size and hopper design |

How to choose for your application

Use these practical checkpoints.

- Start with material form. Film and light packaging often benefits from cutter compactor densification. Thick parts and large lumps typically require shredding.

- Define your downstream bottleneck. If your extruder is the limiting step, stable feeding becomes critical and favors cutter compactor systems. If your bottleneck is opening and cutting bulky scrap, start with a shredder.

- Check contamination and variability. Mixed rigid streams or inconsistent scrap sizes are safer with shredding first. Cleaner, more uniform film streams can go directly to cutter compaction.

Integrated system options

Many recycling plants combine both approaches.

- Film line: cutter compactor plus extruder and pelletizer for consistent throughput.

- Rigid line: shredder plus washing and separation, then extrusion and pelletizing. If you need a turnkey approach, start with a complete plastic washing line configuration and scale capacity around your input stream (sistema de lavado de reciclaje).

- Hybrid: shred bulky film bales first, then cutter compaction for stable extrusion feeding.

For additional background on plastic materials and recycling pathways, see the U.S. EPA overview of plastics and recycling (EPA). For material identification and typical resin uses, the Society of the Plastics Industry resin identification codes are a helpful reference (Asociación de la Industria del Plástico).

Conclusión

Choosing between a cutter compactor and a shredder is not about which machine is better. It is about which machine matches your material behavior and the needs of your extrusion step.

If you recycle PE and PP film and need steady feeding, a cutter compactor system is often the most direct path to stable pellet output. If you process thick, rigid, bulky scrap or purge, a shredder is usually the first essential step.

When your goal is to sell higher-value, easy-to-handle product instead of loose flakes, a dedicated pelletizing line is the usual next step (peletizadores de plástico).

Preguntas frecuentes

- Q1: What is the main difference between a cutter compactor and a shredder

- A1: A cutter compactor cuts and densifies soft plastics to stabilize feeding into an extruder. A shredder focuses on strong size reduction for bulky or rigid plastics.

- Q2: Can a shredder process PE film

- A2: It can, but feeding and output density may be inconsistent. Film lines often perform better with cutter compaction or a shredder plus a dedicated densifying stage.

- Q3: Do cutter compactors require pre cutting

- A3: Many cutter compactor systems can process film directly without a separate crusher, depending on film thickness, contamination, and bale condition.

- Q4: When do you need both machines

- A4: When the input stream includes bulky scrap that must be opened and reduced first, but extrusion still requires stable feeding. A common layout is shredder first, then cutter compaction or controlled feeding into the extruder.