Introducción

Elegir el sistema de peletización adecuado para su línea de producción de PET es una decisión crucial que puede afectar significativamente su eficiencia operativa, la calidad del producto y los costos a largo plazo. Entre los métodos más utilizados se encuentran peletización de anillo de agua y peletización de hebras refrigeradas por aguaCada sistema tiene sus ventajas y se adapta a diferentes objetivos de producción y limitaciones de las instalaciones.

En Máquina EnergycleNos especializamos en ayudar a fabricantes de EE. UU. y Europa a optimizar sus líneas de reciclaje y procesamiento de polímeros. Si está explorando sistemas diseñados para escamas de PET, visite nuestro sitio web. Peletizadora de un solo tornillo de escamas de plástico PET Página para obtener más información sobre soluciones de tornillo único de alta eficiencia.

Esta guía detallada lo guiará a través de una comparación equilibrada de ambas tecnologías de peletización, ayudándolo a determinar la que mejor se adapta a sus necesidades específicas.

Comprensión de los conceptos básicos de la peletización de PET

La peletización de PET (tereftalato de polietileno) es un proceso posterior en la línea de producción de reciclaje de plástico o polímero virgen, donde el PET fundido se convierte en pellets sólidos. Estos pellets son más fáciles de manipular, transportar y reutilizar en los procesos de fabricación.

Los dos sistemas dominantes son:

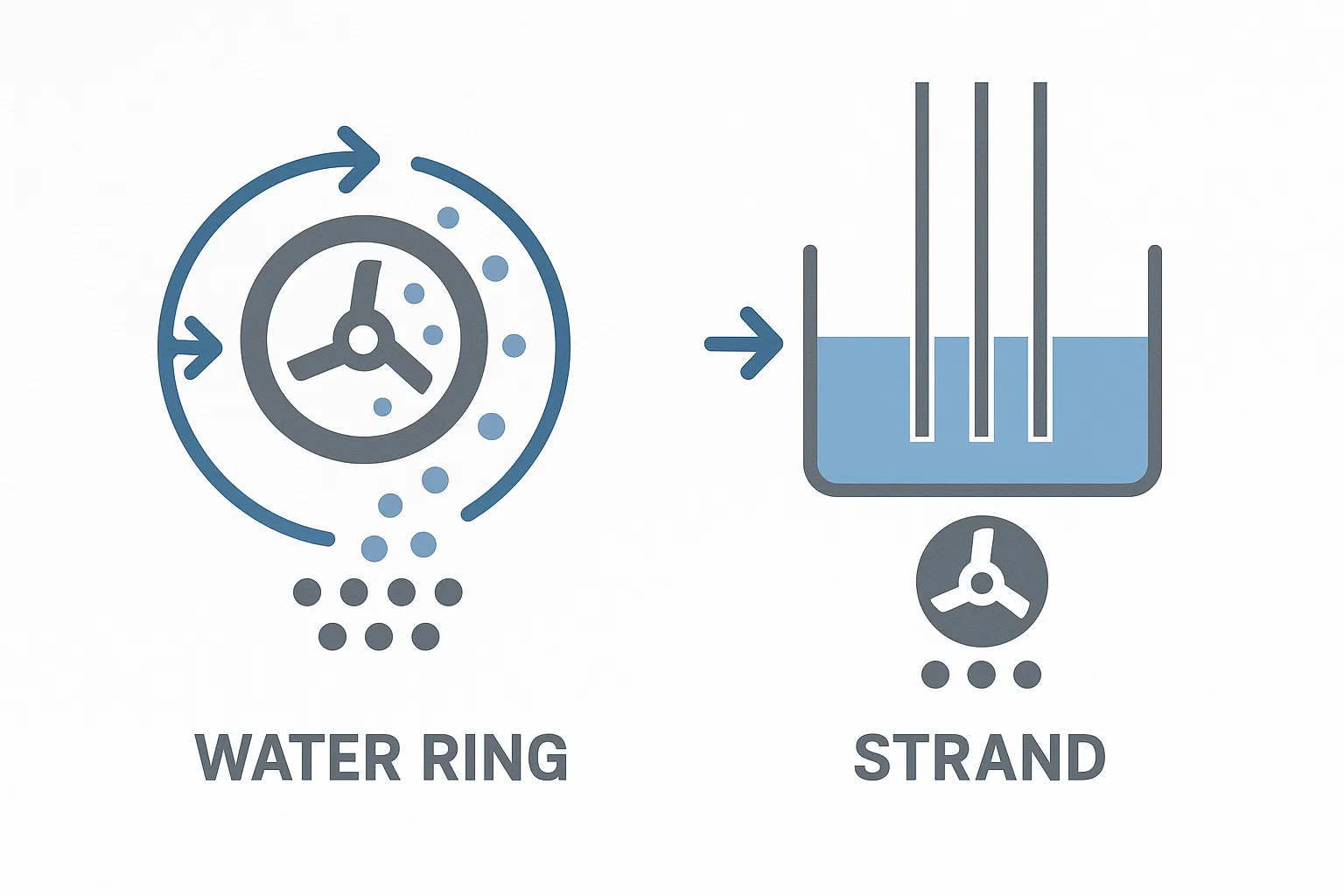

- Peletización por anillo de aguaEl PET fundido se extruye a través de una matriz y se corta inmediatamente en gránulos mediante cuchillas giratorias. Posteriormente, los gránulos se enfrían en un anillo de agua circulante.

- Peletización de hebras refrigeradas por agua:El PET fundido se extruye en hebras continuas, se enfría en un baño de agua y luego se corta en gránulos.

Para escamas de botellas de PET, Máquina Energycle También ofrece sistemas de peletización especializados Diseñado para una producción estable y una calidad de pellet constante.

Requisitos de espacio y huella

Peletización por anillo de agua

Los sistemas de anillo de agua son compactos y altamente integrados. Ocupan menos espacio, lo que los hace ideales para instalaciones donde el espacio es limitado. Todos los componentes principales, incluyendo el cortador, el anillo de agua y el secador, suelen ensamblarse como una sola unidad.

Peletización de hebras refrigeradas por agua

Los sistemas de filamentos requieren mayor espacio en planta debido a los canales de agua de refrigeración y la disposición de los filamentos. Esta configuración puede ser limitada para fábricas pequeñas o instalaciones de modernización. Sin embargo, puede ofrecer mayor flexibilidad para manejar diferentes viscosidades de materiales.

Máquina Energycle recomienda evaluar el diseño de su planta para comprender qué sistema se adapta mejor a su espacio operativo.

Automatización y facilidad de uso

Peletización por anillo de agua

Los sistemas de anillo de agua suelen estar más automatizados y requieren menos intervención del operador. La presión de las cuchillas suele ser autoajustable y el secado de pellets está integrado, lo que reduce la necesidad de manipulación manual.

Peletización de hebras refrigeradas por agua

Los sistemas de peletización de hebras requieren más mano de obra. Los operadores deben garantizar una correcta alineación de las hebras y un flujo de agua constante. El arranque y la parada requieren mayor atención y habilidad.

Para los fabricantes que buscan reducir los costos laborales y mejorar la consistencia, Máquina Energycle sugiere considerar la peletización de anillo de agua por sus beneficios de automatización.

Forma y calidad de los pellets

Peletización por anillo de agua

Produce pellets redondeados y uniformes con un acabado brillante. Son especialmente beneficiosos para aplicaciones de alta gama donde la estética y la fluidez del pellet son cruciales.

Peletización de hebras refrigeradas por agua

Los pellets suelen ser cilíndricos con extremos ligeramente irregulares. Si bien son funcionales para la mayoría de los usos posteriores, es posible que no cumplan con los estándares estéticos o de procesamiento más exigentes.

Si la uniformidad y la apariencia de los pellets son fundamentales para su aplicación, Máquina Energycle Recomienda sistemas de anillo de agua.

Tabla comparativa resumida

| Característica | Peletización por anillo de agua | Peletización de hebras refrigeradas por agua |

|---|---|---|

| Huella | Compacto | Se necesita más espacio |

| Automatización | Alto | Medio a bajo |

| Forma de pellet | Redondo, uniforme | Cilíndrico, variable |

| Mantenimiento | Moderado | Menor riesgo de desgaste |

| Costo inicial | Más alto | Más bajo |

| Costo de operación | Bajar a largo plazo | Mayor coste laboral |

| Rendimiento | Alto | Medio |

| Flexibilidad del material | Medio | Alto |

Preguntas frecuentes

P1: ¿Puedo instalar un peletizador de anillo de agua en mi línea de PET existente?

Sí, muchos de Máquina EnergycleLos modelos están diseñados para modernización, pero se deben evaluar los parámetros de diseño y extrusión.

P2: ¿Qué peletizadora es más adecuada para el PET reciclado?

La peletización con anillo de agua suele ser mejor para el PET reciclado debido a su mayor rendimiento y su integración de secado superior.

P3: ¿Hay sistemas híbridos disponibles?

Algunos sistemas ofrecen opciones modulares que combinan características de ambos tipos de peletización. Máquina Energycle Puede consultar sobre soluciones personalizadas.

P4: ¿Cuál es el período de recuperación típico para la actualización a un sistema de anillo de agua?

Dependiendo de su producción y de los costos laborales, el período de recuperación puede variar entre 1 y 3 años.

Tome la decisión correcta para su línea de producción

Elegir el sistema de peletización adecuado puede determinar el futuro de su línea de producción de PET. Máquina Energycle ayudarle a realizar una inversión informada y con garantía de futuro.

Visita nuestra Peletizadora de un solo tornillo de escamas de plástico PET página o contáctenos hoy para discutir sus necesidades.

Solicitar un presupuesto personalizado