Polystyrene recycling is often described as difficult, but the barrier is usually not chemistry—it’s collection and transport. Expanded polystyrene (EPS) foam takes up a lot of space relative to its weight. Without densification, storage and freight costs can dominate the economics.

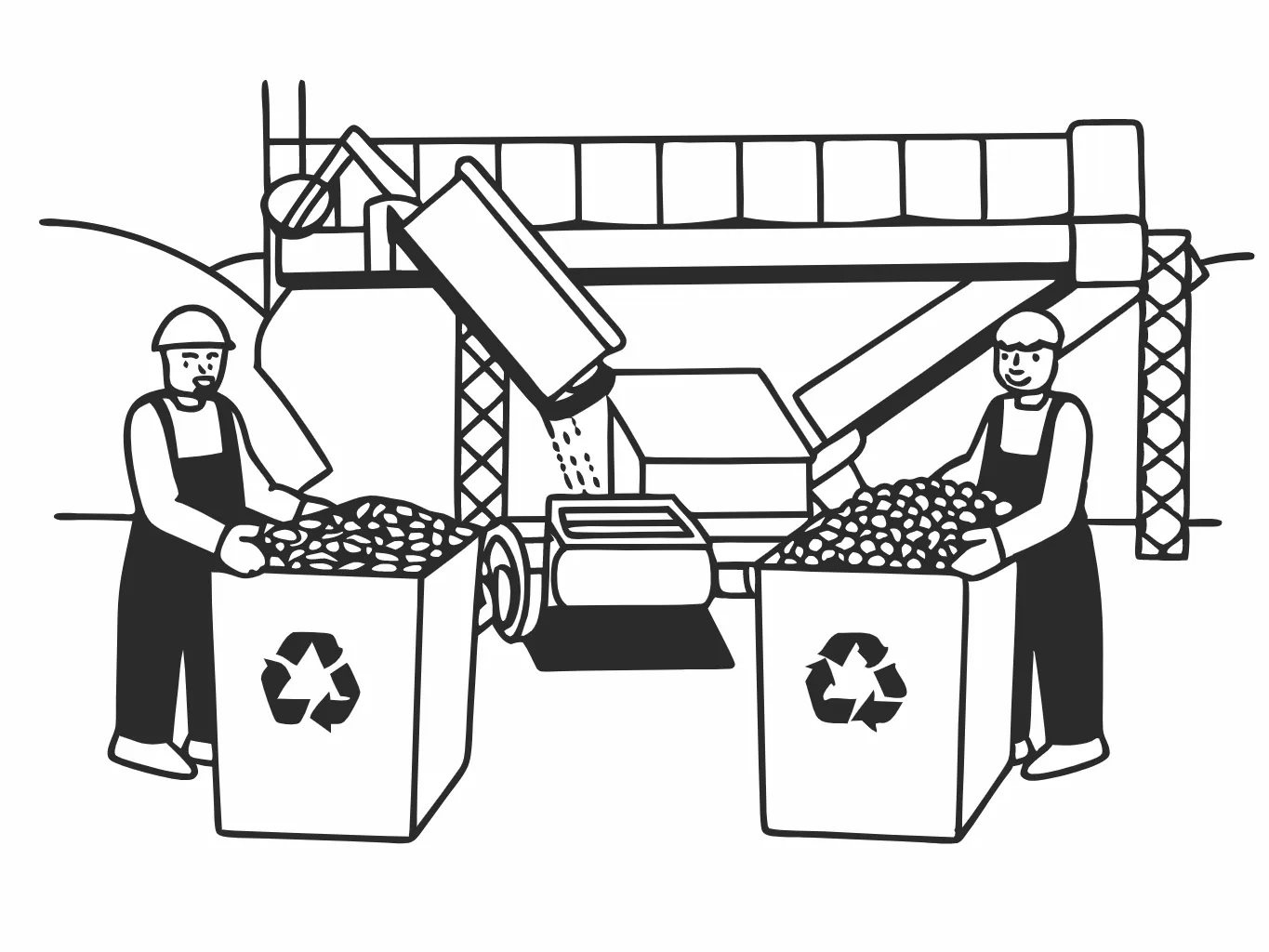

Polystyrene recycling machines solve that problem by converting loose foam into denser formats that are easier to handle, ship, and reprocess into pellets or other products.

Conclusiones rápidas (para compradores)

- If your stream includes EPS foam, densification is usually the first step that makes a recycling program workable.

- The “right” machine depends on output format (logs/ingots/pellets), contamination level, and how centralized your processing will be.

- If you plan to pelletize PS, treat sorting, cleaning, and melt filtration as core requirements—not add-ons.

PS vs EPS: Know What You’re Handling

Polystyrene shows up in multiple forms: – Rigid PS (often GPPS/HIPS) used in various rigid products and packaging – Espuma EPS used for cushioning and insulation because of its low bulk density

APR’s PS/EPS design guidance notes that EPS’s low bulk density is one reason it’s used for insulation and cushioning, and also highlights that collection access can be limited in many regions—so your business case needs a realistic view of collection and logistics, not only processing equipment. (Source: APR PS/EPS Design Guidance)

The Three Output Formats That Drive Your Equipment Choice

Most buyers end up choosing one of these “output paths.” Each path has different capex, utilities, and operational risk.

| Output format | ¿Qué es | What machines you usually need | Where it fits |

|---|---|---|---|

| Compacted EPS logs | Mechanically compressed foam (not fully melted) | EPS compactor + basic sorting and storage | Clean packaging foam streams; distributed collection sites feeding a central processor |

| Thermal densified ingots | Foam collapsed by heat into dense blocks | Thermal densifier + ventilation + safe handling/collection | Sites that need higher density for shipping and can support ventilation and heat management |

| PS pellets | Extruded and pelletized recycled PS | Densification (if EPS) + shredding/grinding + extrusion + melt filtration + pelletizing | Operations selling standardized feedstock to converters; higher quality control expectations |

If you want a process walkthrough, see Energycle’s EPS recycling machine workflow overview and its overview of expanded polystyrene (EPS) recycling machines.

Core Machine Modules (What Actually Matters in Daily Operation)

1) Sorting and contamination control

PS and EPS value drop quickly when streams are mixed with other plastics, paper, food residue, or fines. Define what you will accept and how you will reject.

Buyer checks: – how material is inspected (incoming QC) – how mixed plastics are removed (manual or automated) – how food-contact packaging is handled (contamination risk management)

2) Densification (for EPS streams)

This is the module that changes the logistics cost curve.

Two common approaches: – Cold compaction (mechanical): compresses foam into logs. Simpler and often lower utility requirements. – Thermal densification: collapses foam with heat into ingots. Can reach higher density but requires ventilation and heat management.

3) Size reduction (when you plan to pelletize)

Densified material still needs stable feeding into an extruder. That usually means shredding or grinding to a controlled size.

4) Extrusion, filtration, and pelletizing (when you sell pellets)

If your output goal is standardized pellet, you will be judged on consistency. That typically means: – stable feeding (avoid surging) – melt filtration matched to contamination load – pelletizing method matched to the polymer and the plant’s operating model

For downstream options, Energycle’s máquinas peletizadoras de plástico page is a useful reference for line configurations.

What to Put in an RFQ (So Quotes Are Comparable)

| RFQ item | Por qué es importante | What to specify |

|---|---|---|

| Material form | EPS vs rigid PS changes the whole line | EPS foam vs rigid PS; typical piece size; contaminants |

| Contamination profile | Drives sorting, cleaning, and filtration needs | Paper/labels, food residue, mixed plastics, fines |

| Output format | Defines machine type and utilities | Logs/ingots/pellets; packaging and handling requirements |

| Rendimiento y ciclo de trabajo | Determines sizing and maintenance plan | Objetivo de kg/h y turnos/día; cargas pico vs. cargas promedio |

| Utilities and site limits | A menudo bloquea proyectos después de la compra. | Available power, ventilation limits, space, noise constraints |

Market and Compliance Notes (What Affects Sale Price)

For PS and EPS projects, equipment selection is only half the job. Sale price depends on whether your output can meet a buyer’s application requirements:

- Odor and residue: food-service EPS can carry residues that create odor complaints. If your end market is sensitive, plan more aggressive cleaning and tighter incoming QC.

- Contamination tolerance: PS buyers often focus on visible specks and mixed polymer carryover. Define sampling and lot segregation rules so “one bad load” does not contaminate a full day’s production.

- Food-contact ambition: if you are targeting food-contact applications, consult the relevant regulatory guidance early and expect stricter documentation and process control. In the U.S., FDA publishes guidance on chemistry considerations for recycled plastics in food packaging. (Source: U.S. FDA guidance)

Preguntas frecuentes (Preguntas reales sobre adquisiciones)

Is EPS foam actually recyclable, or is it “technically recyclable but not collected”?

Both statements can be true depending on your region. Mechanically, EPS can be processed when you can collect it cleanly and densify it so shipping makes sense. The practical barrier is often that EPS is bulky, so collection and transport costs can exceed the value of the material unless densification happens early. APR’s PS/EPS design guidance also notes that collection access for PS or EPS can be limited in some areas, which is why a recycling plan should start with realistic collection channels and contamination control. Treat equipment as the second step after you validate supply and buyers. (Source: APR PS/EPS design guidance)

Should I buy a cold compactor or a thermal densifier for EPS?

Choose based on your input cleanliness, utilities, and the logistics model. Cold compactors are usually simpler to run and can fit cleaner packaging foam streams. Thermal densifiers can create a denser output but add heat management and ventilation requirements. The bigger decision is where densification happens: on-site at collection points (to reduce shipping volume) or at a centralized processor. If you are unsure, start with the output format your downstream buyer prefers and then pick the simplest densification method that meets that handling spec.

Can I go directly from EPS densification to pellets?

Not usually without additional steps. Densification makes EPS shippable, but pellet output depends on consistent feeding, melt filtration, and stable extrusion. In most plants, densified PS is size-reduced (shredded or ground) for stable feeding, then extruded with filtration sized for the contamination load, then pelletized. If your incoming foam has food residue or mixed plastics, expect sorting and cleaning requirements to rise quickly. If pellets are your goal, ask suppliers to quote the full line concept, not only the densifier.

What are the biggest quality risks when making recycled PS pellets?

Contamination and variability. Mixed polymers, paper, and residue can show up as gel-like defects, odor issues, or unstable processing. Your process needs clear incoming QC rules, a sorting plan, and a filtration strategy that matches the real contamination load. It also helps to define what “pass” means for your customer: melt flow consistency, visual contamination limits, and odor expectations. Treat pellet quality as a system outcome (collection + sorting + filtration + pelletizing), not as a feature of the extruder alone. Ask suppliers to propose a trial plan tied to your acceptance tests.

Does PS recycling require special design guidance for packaging and labels?

If your stream includes packaging, it helps to understand how packaging design affects recyclability and contamination risk. APR maintains PS/EPS design guidance that covers both rigid PS and EPS and discusses how components like labels, inks, and adhesives can affect recycling streams. Even if you are not a packaging designer, the guidance is useful because it explains what types of components typically create problems in mechanical recycling. Use it to build your incoming QC rules and to explain rejection reasons to suppliers. (Source: APR PS/EPS design guidance)

Where can I check broader plastics recycling context and definitions?

For standards context, ISO 15270 provides guidance on plastics waste and recycling. For U.S. national-level materials context, the EPA publishes plastics material-specific data within its “Facts and Figures” reporting framework, which can help you sanity-check how plastics are tracked and discussed at a high level (it won’t replace your own market research, but it helps avoid confusion). For polystyrene-specific collection efforts and roadmaps, the Polystyrene Recycling Alliance (PSRA) publishes materials focused on expanding access and capacity. (Sources: Descripción general de la norma ISO 15270, U.S. EPA plastics material-specific data, PSRA)

Referencias

- Energycle — EPS recycling workflow

- Energycle — Overview of EPS recycling machines

- Energycle — Máquinas peletizadoras de plástico

- Asociación de Recicladores de Plástico (APR) — Guía de diseño de PS/EPS

- U.S. EPA — Plastics material-specific data (Facts and Figures)

- Polystyrene Recycling Alliance (PSRA)

- ISO — Directriz de reciclaje de plásticos (descripción general de la norma ISO 15270)

- U.S. FDA — Chemistry considerations for recycled plastic in food packaging (guidance)